Heating sterilization protective cover for total heat exchange core and total heat exchange structure

A full heat exchange core, heating and sterilization technology, applied in heating, household heating, heating methods, etc., can solve the problem of the full heat exchange core being prone to moisture and mildew, and achieve the effect of strong applicability and improved heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

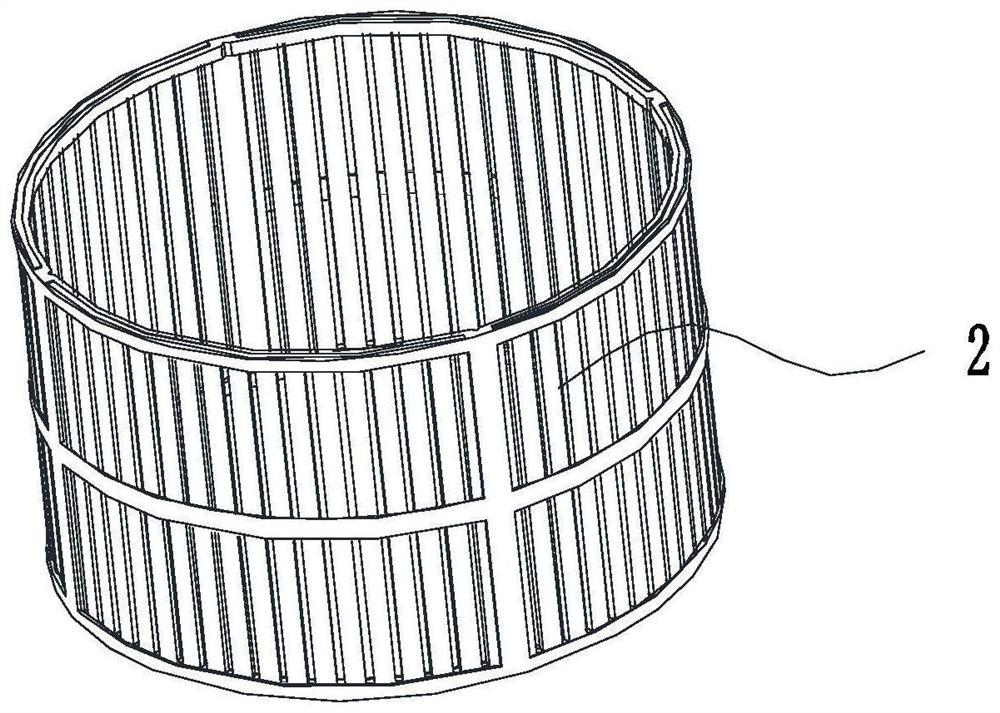

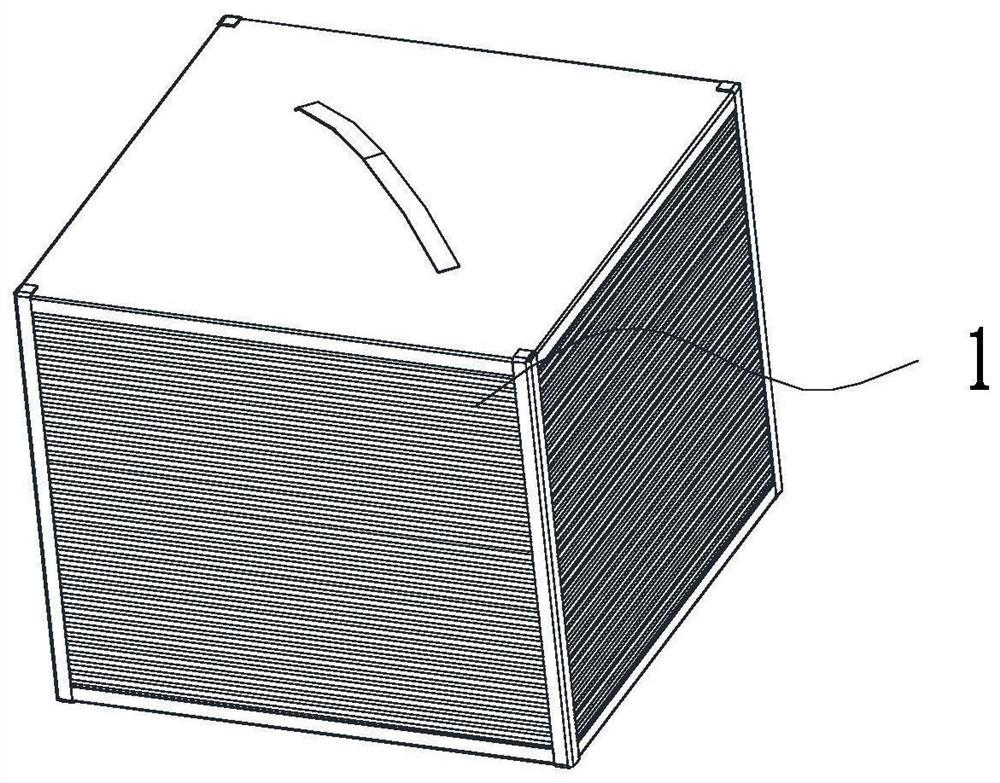

[0037] This embodiment provides a heat sterilization protective cover 2 for the total heat exchange core 1, specifically as Figure 2-12 As shown: it includes a cover body 3 with a heating element 31 and a detachable snap-fit structure 32 provided on the outer surface of the total heat exchange core 1 on the cover body 3 . By providing a heating and sterilization protective cover 2 detachably arranged on the total heat exchange core 1, when the total heat exchange core 1 is not performing fresh air heat exchange, the heating and sterilization protection cover 2 is opened, and the total heat exchange core 1 Realize high-temperature heating and sterilization, which solves the problem that the total heat exchange core 1 is prone to moisture and mold in the prior art. At the same time, when the total heat exchange core 1 is performing heat exchange with fresh air, the heating and sterilization protective cover 2 is opened to realize heating of outdoor fresh air Sterilize.

[00...

Embodiment 2

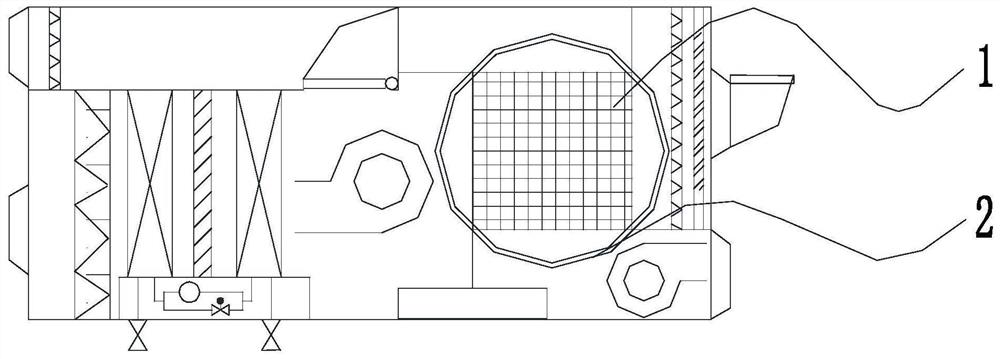

[0048] This embodiment provides a total heat exchange structure, such as figure 1 As shown, it includes a total heat exchange core 1, and the total heat exchange core 1 is provided with the heat sterilization protective cover 2 mentioned in the above embodiment. A fitting structure 32 is arranged on the heating and sterilization cover, so that the heating and sterilization cover can be detachably fixed on the total heat exchange core 1 . Further, the total heat exchange core 1 is provided with a connecting portion corresponding to the engagement structure 32 of the heat sterilization protective cover 2. During the specific implementation process, when the engagement structure 32 provided on the heat sterilization cover is a concave groove 321, The total heat exchange core 1 is provided with a protruding strip corresponding to the concave groove 321; The concave groove 321 corresponding to the bar. When only the groove 323 is provided on the support frame 33, the total heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com