Sewing machine presser foot device

A technology for sewing machine presser feet and sewing machines, which is applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., and can solve problems affecting sewing effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

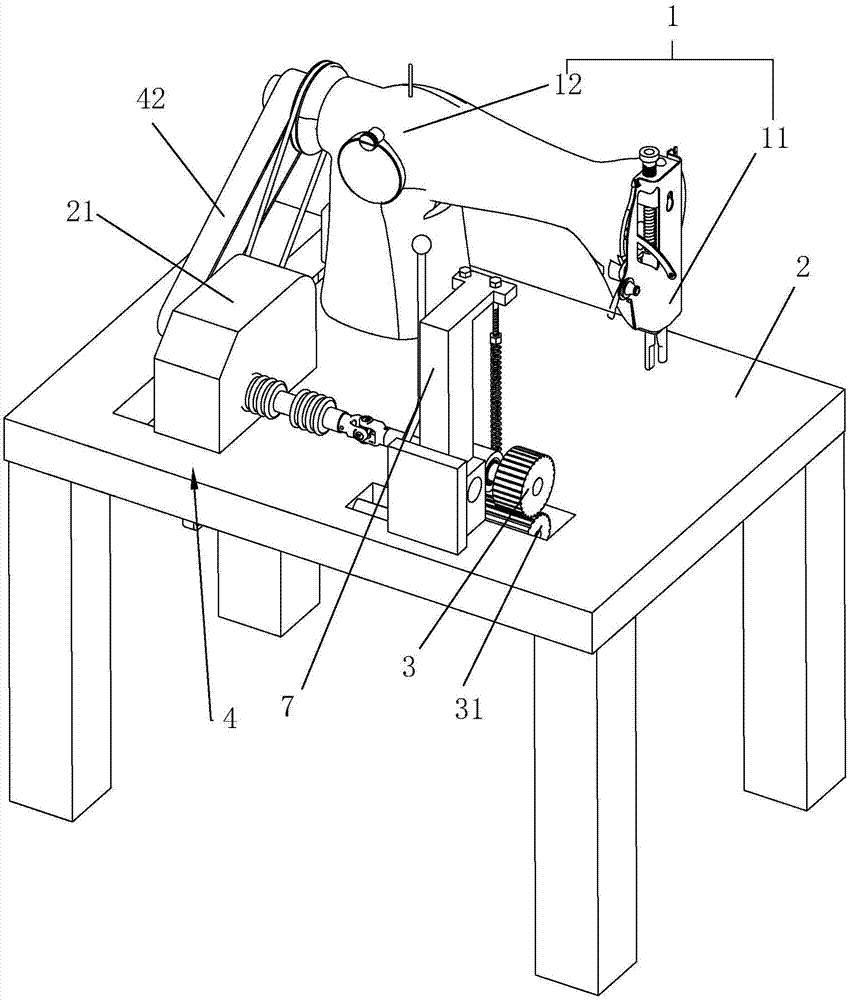

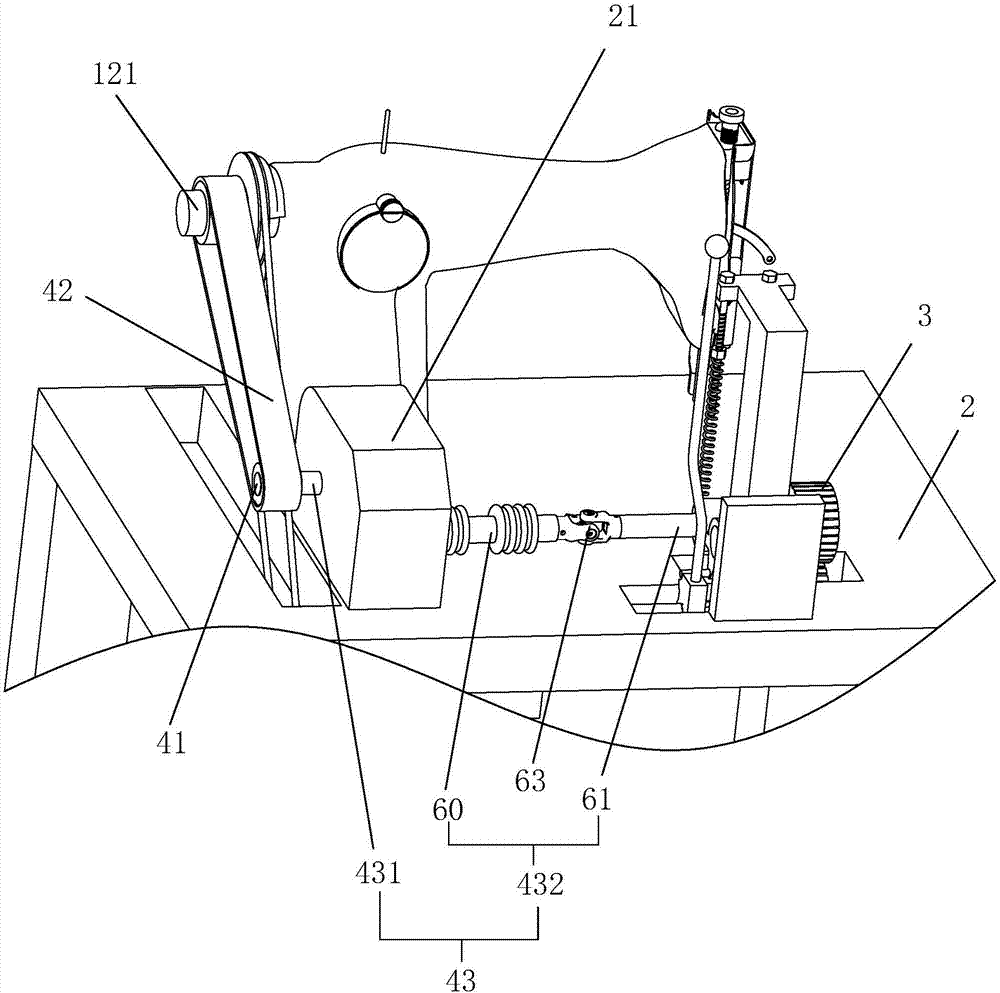

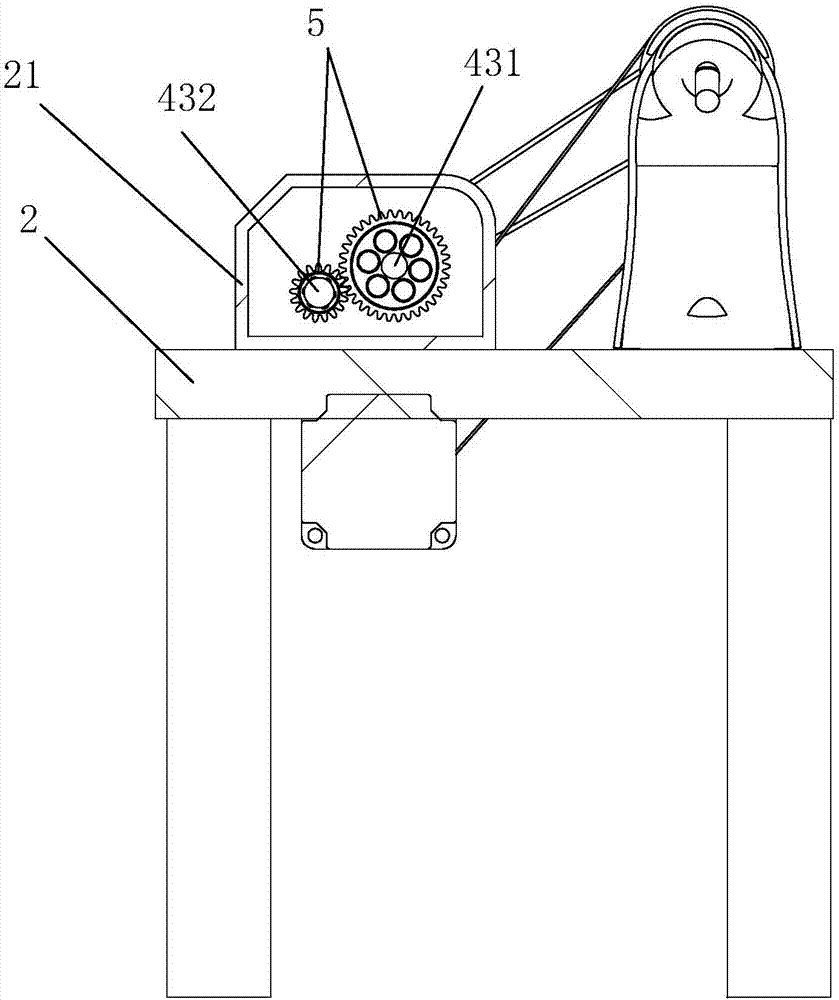

[0038] refer to figure 1 A sewing machine presser foot device installed on a sewing machine is used to limit the moving direction of the sewn cloth, to prevent the sewn cloth from falling off the surface of the sewing machine seat, to drive the cloth to be sewn to rotate, and to affect the sewing effect.

[0039] refer to figure 1 , the sewing machine includes a machine head 1 and a machine base 2 for supporting the machine head 1, and the machine head 1 includes a sewing part 11 and a driving part 12 for driving the sewing part 11 to sew. The sewing machine presser foot device disclosed in the present invention includes a presser foot post 3 that is rotatably connected to one end of the top of the machine base 2 close to the sewing part 11. The presser foot post 3 is located on the side of the sewing part 11 away from the operator, and the presser foot post 3 can be opposite to the sewing machine. The top lifts. Be positioned at the below of presser foot column 3 in support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com