Clothes tailoring scriber

A scriber and clothing technology, which is applied in the field of clothing, can solve the problems of easy crooked lines, clothing fabric folds, affecting clothing scribing, etc., and achieve the effect of fast and convenient scribing and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

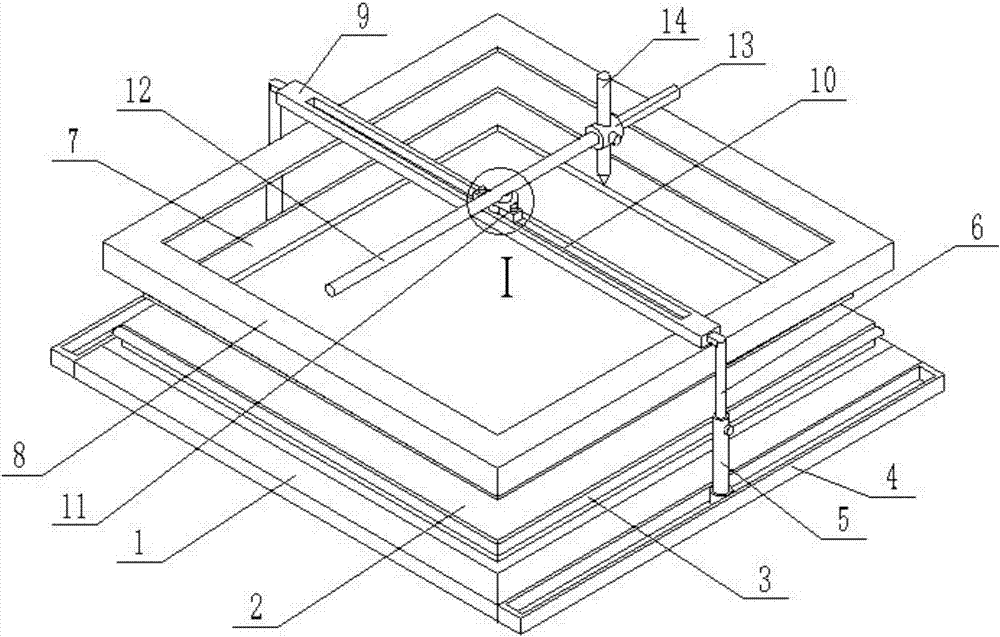

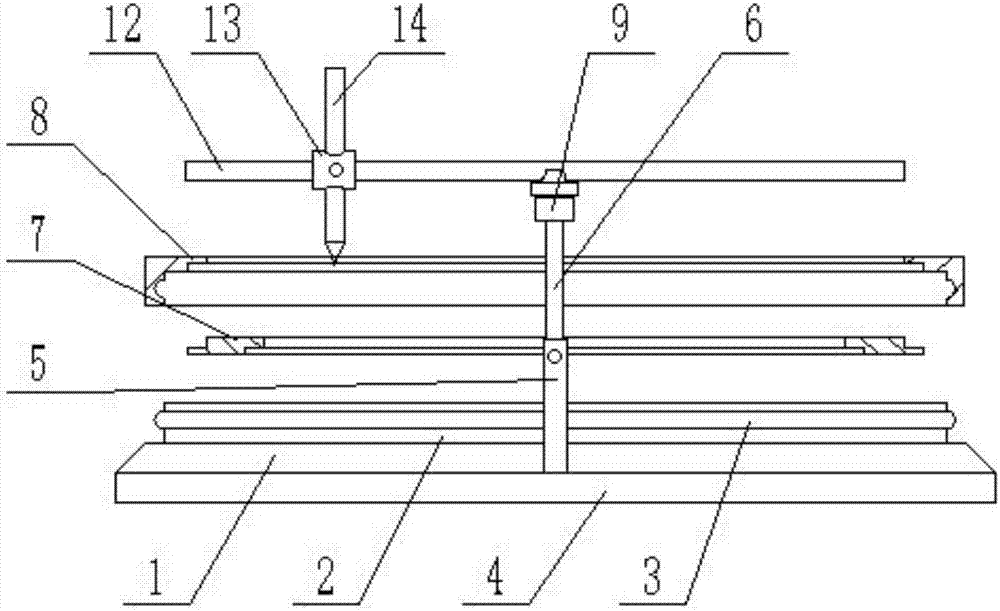

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail

[0023] as attached Figure 1-4 The shown garment cutting and marking device of the present invention includes: a base 1, a cloth pallet 2, a raised ring 3, a guide rail groove 4, a sleeve 5, a telescopic rod 6, an inner pressure ring 7, and an outer clip Ring 8, top frame 9, chute 10, mounting seat assembly 11, guide rod 12, ring 13 and marking pen 14.

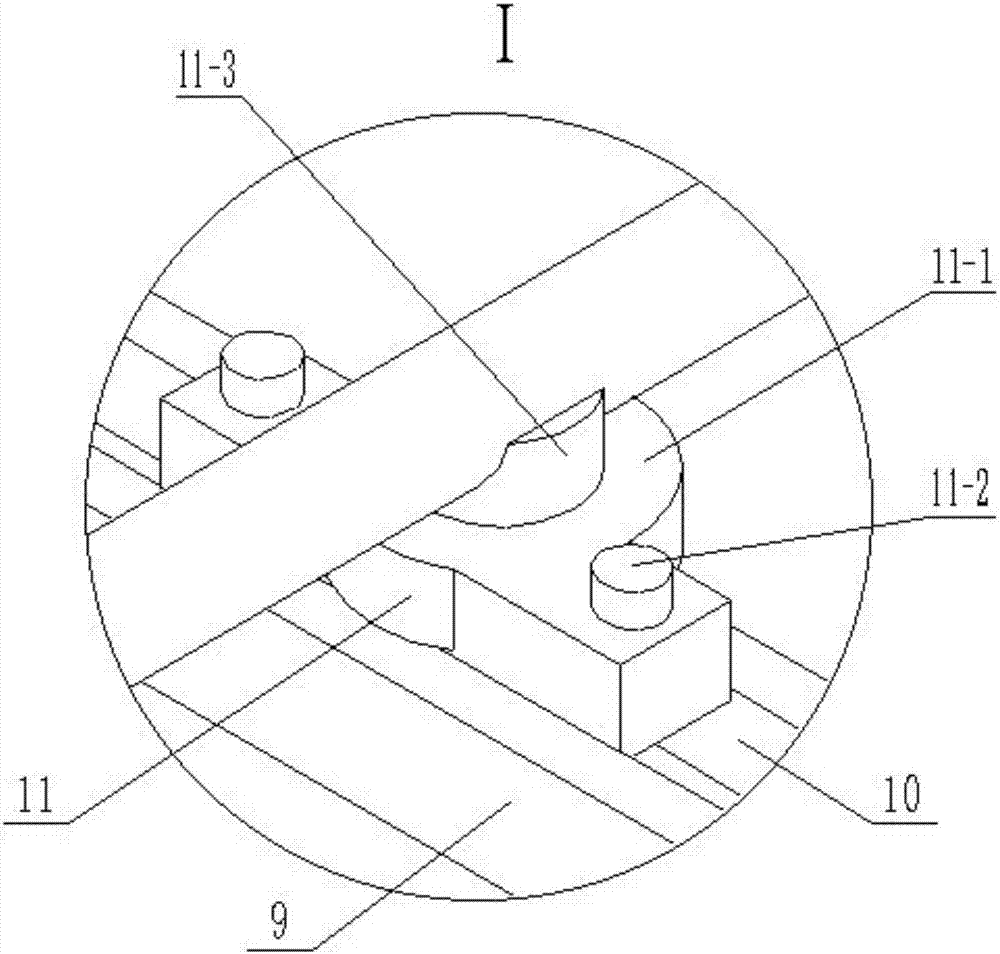

[0024] Mounting seat assembly 11 comprises mounting seat main body 11-1, sliding locking screw 11-2, rotating column 11-3, rotating locking screw 11-4 and T-shaped guide slider 11-5, the mounting seat main body 11-1 A sliding locking screw 11-2 is respectively arranged on the left and right sides, and a rotating post 11-3 is movably installed on the top of the mounting seat main body 11-1, and the rotating locking screw 11-4 connects the rotating post 11-3 with the mounting seat main body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com