Fully automatic sound velocity measuring instrument and measurement method

A fully automatic, measuring instrument technology, applied in measuring devices, measuring propagation velocity, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of difficult to accurately find the maximum position of the waveform, complicated experimental steps, difficult to determine the accuracy, etc., to achieve Intuitive effect, high data collection efficiency, and effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

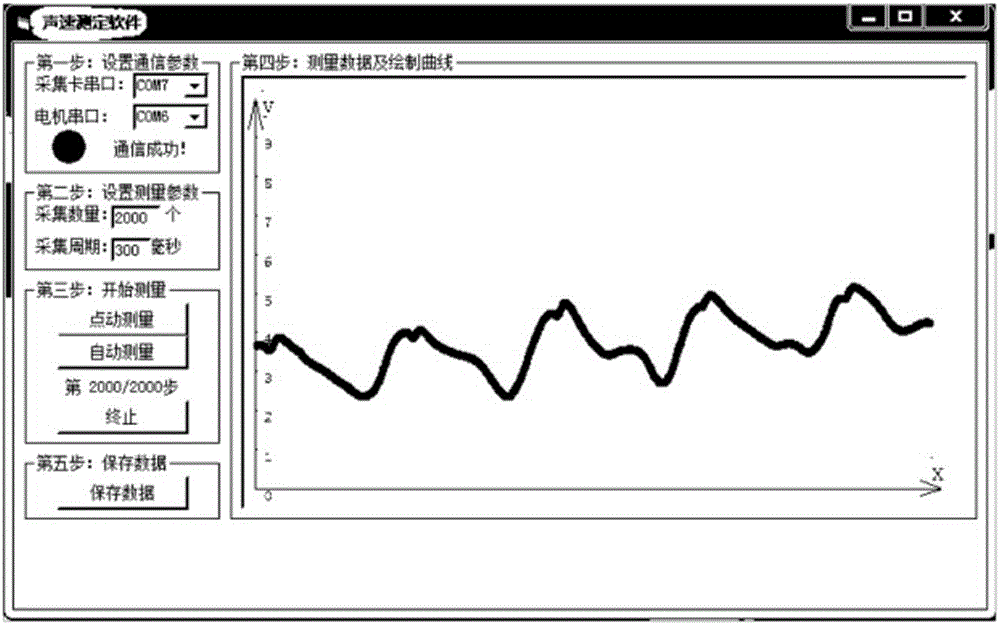

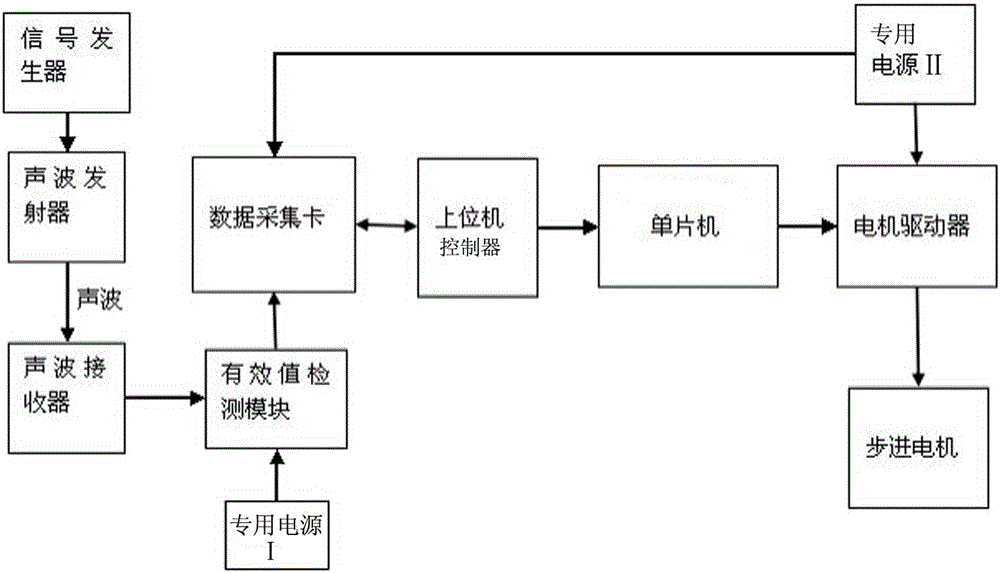

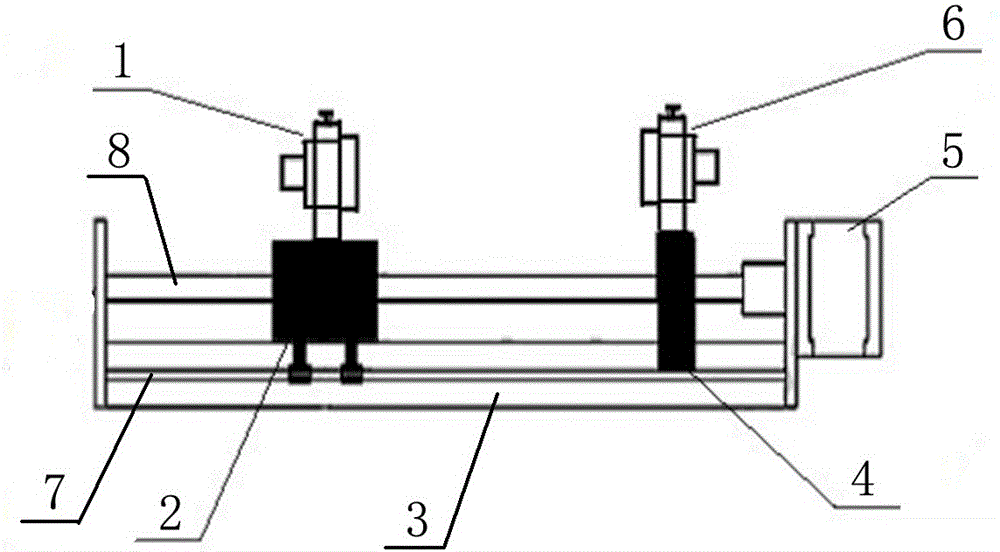

[0028] see figure 1 and figure 2 , a fully automatic sound velocity measuring instrument, comprising a host computer controller, a signal generation system, a sound wave receiver displacement system and a data acquisition system, the inside of the host computer controller is provided with sound velocity measurement software in a C language programming mode; the signal The generating system includes a signal generator, and the signal generator is connected with the sound wave transmitter 6; the data acquisition system includes the sound wave receiver 1, and the sound wave receiver 1 is connected with an effective value detection module, and the effective The value detection module is connected with a data acquisition card, and the data acquisition card is connected with the host computer controller through a bidirectional converter; the acoustic wave receiver displacement system includes a single-chip microcomputer, a stepping motor driver and an acoustic wave receiver displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com