Hydraulic motor sealing performance detection device

A sealing detection and hydraulic motor technology, which is applied in fluid pressure actuation devices, liquid tightness measurement using liquid/vacuum degree, fluid pressure actuation system testing, etc. It can solve the problems of high cost, laborious and laborious hydraulic motors, etc. , to achieve the effect of stable movement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

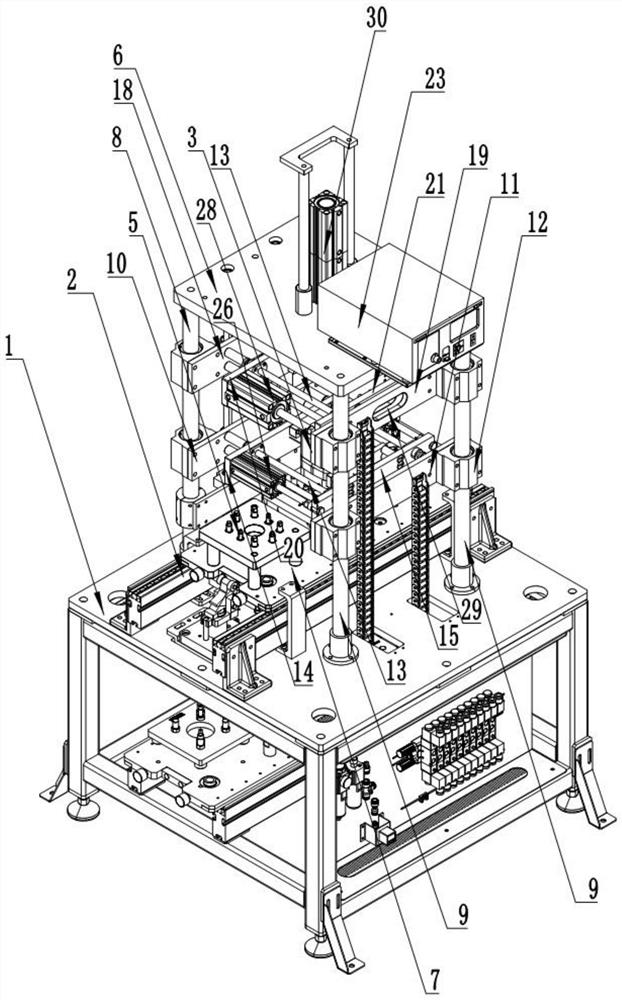

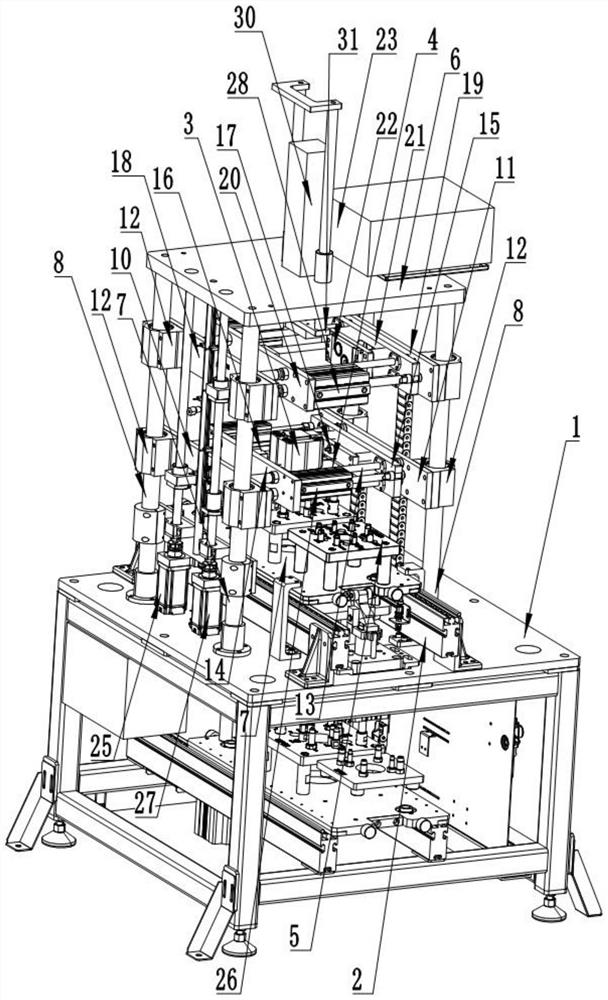

[0031] figure 1 and figure 2 An embodiment of the hydraulic motor 3 leak detection device of the present invention is shown. Please refer to figure 1 and figure 2 It includes a base 1, an air-tightness detection device and a sealing device for sealing the through hole 29 of the hydraulic motor 3. The base 1 is a stainless steel stand, wherein the air-tightness detection device and the sealing device are all arranged on the base 1 On the base 1, a workpiece conveying device 2 is arranged longitudinally, and the workpiece conveying device 2 is provided with a detection station 4 for testing the tightness of the hydraulic motor 3. The position of the detection station 4 is kept fixed relative to the base 1, The workpiece conveying device 2 is provided with several workpiece positioning devices 5 for fixing the hydraulic motor 3 on the outward side. The flat plate is attached, and the positioning column is adapted to the positioning hole at the bottom of the hydraulic motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com