Heading machine with drilling tool, scraper box, coring drilling rod and quartering hammer

A technology of roadheader and coring drill, which is used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of time-consuming, labor-intensive, and difficult drilling, and achieve the effect of avoiding time-consuming and laborious, stable base, and huge power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and examples.

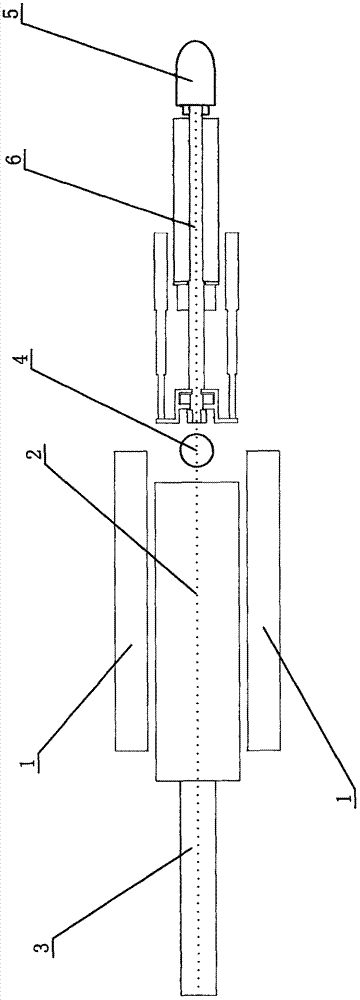

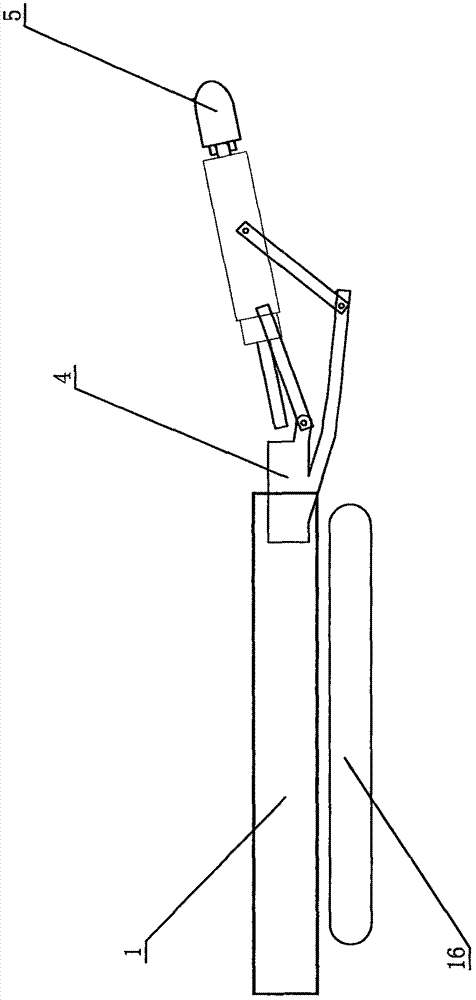

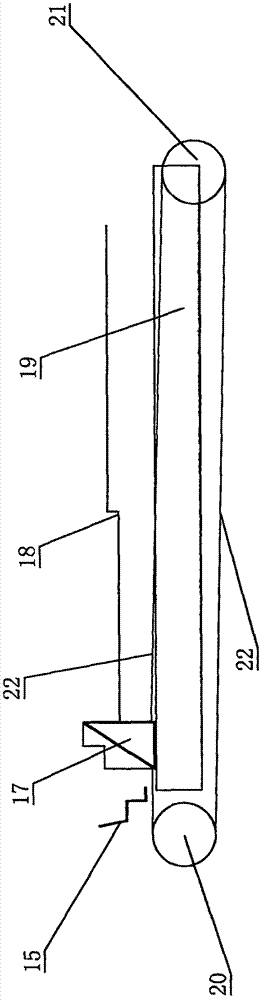

[0033]In the above-mentioned accompanying drawings: the structure of the first embodiment when the present invention is used is shown; Referring to the accompanying drawings, its basic structure is: the roadheader with drilling tool, scraper bucket, coring drill, breaker is an existing The roadheader is reformed from a roadheader, and its feature is: move the hydraulic motors, hydraulic pumps, cooling boxes, transformers, etc. Two single-arm drills 1 are side by side, the fixed seat 17 of the single-arm drill 1, that is, the maximum width of the single-arm drill 1 is less than 0.4 meters, the width of the scraper groove 3 of the roadheader is about 0.9 meters, and the two single-arm drills 1 plus the scraper groove 3 , that is, the total width of the machine is less than 2 meters, and the length is about 16 meters, which is slightly shorter than the existi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com