Winding machine

A winding machine and roll forming technology, which is applied in the direction of thin material processing, conveying filamentous materials, transportation and packaging, etc., can solve the problems of not being able to choose freely, and achieve the effect of highly effective damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

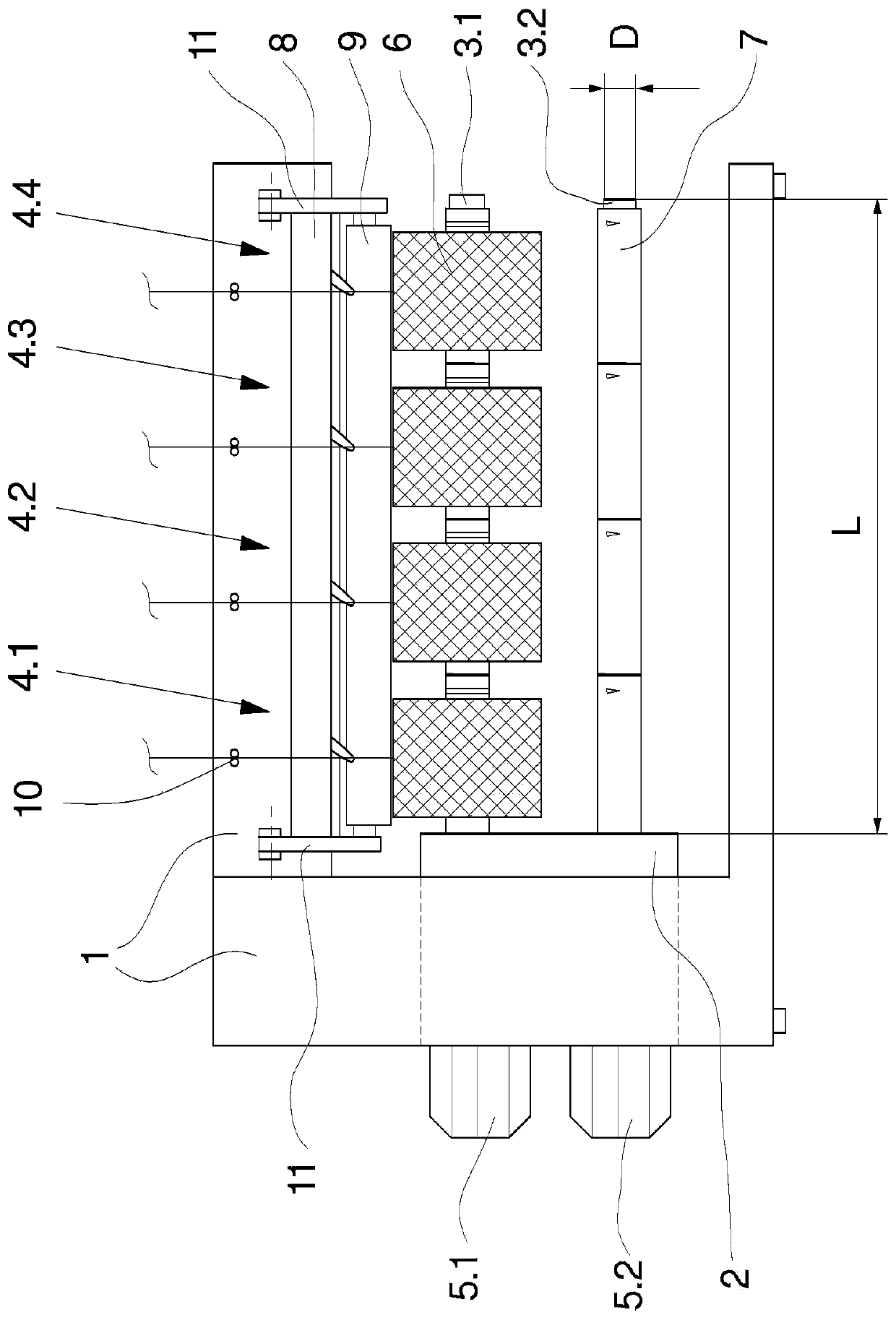

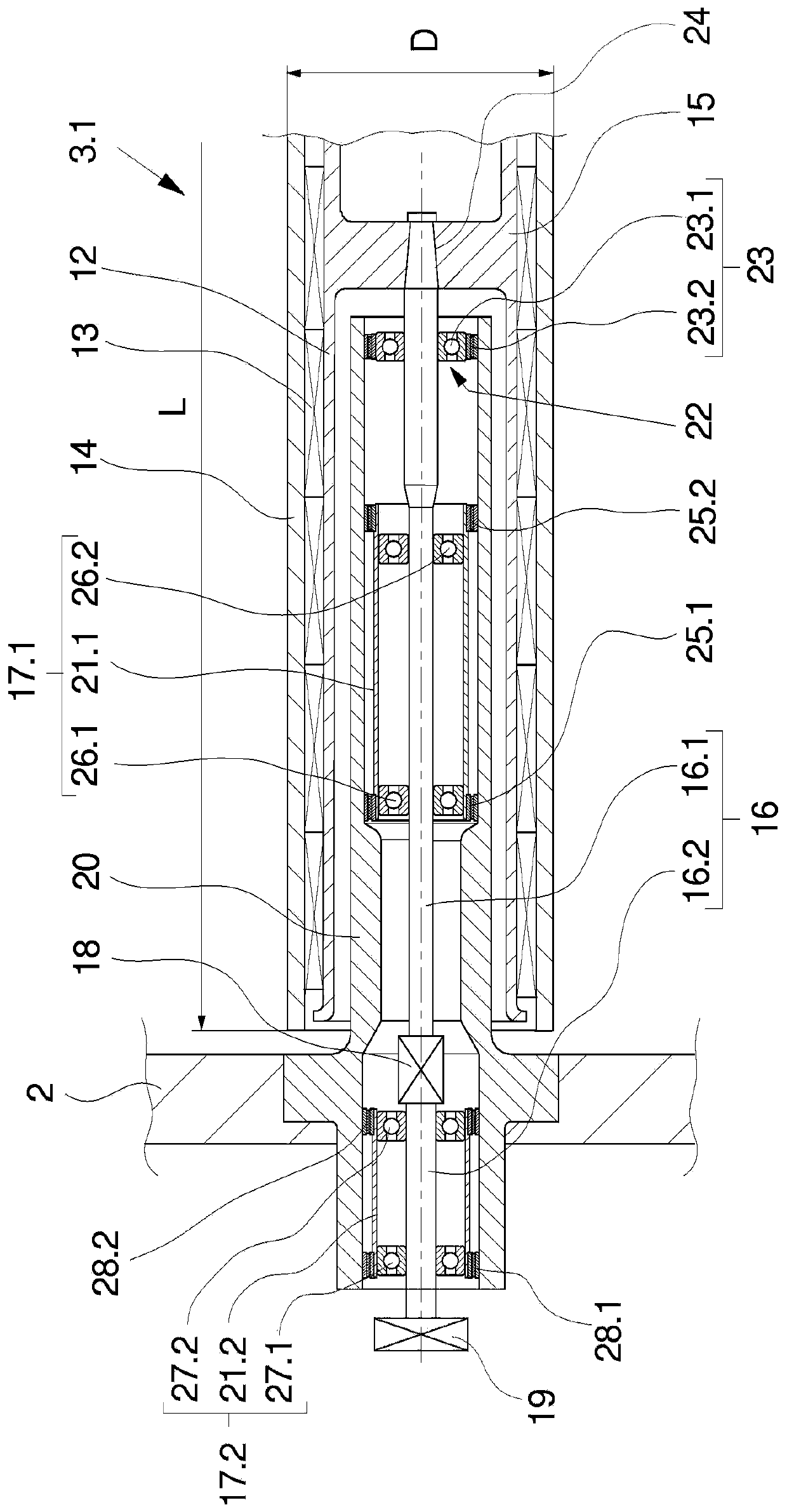

[0027] An exemplary embodiment of a winder according to the invention is in figure 1 is schematically shown in . The winding machine has two substantially protruding winding spindles 3.1 and 3.2 which are arranged on a winding tower 2 which is mounted so that it can be mounted on the machine frame 1 Rotate. Four winding stations 4.1 to 4.4 extend along the winding spindles 3.1 and 3.2, in which four bobbins 6 are wound in parallel. For this, the winding spindles 3.1 and 3.2 are each coupled to one spindle motor 5.1 and 5.2.

[0028] The number of winding stations is exemplary. In principle, a winder of this type has several winding stations in order to wind several bobbins simultaneously.

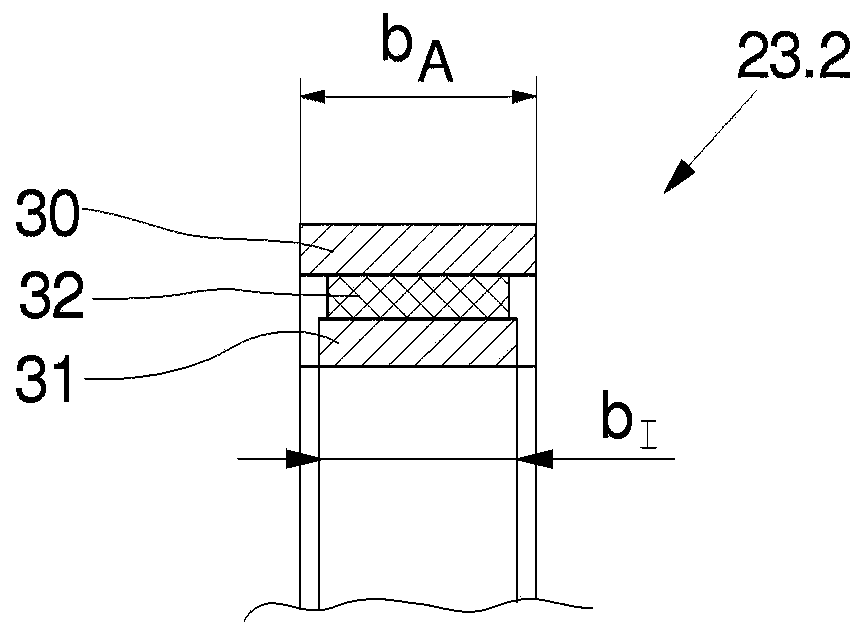

[0029] The winding stations 4.1 to 4.4 are assigned to the contact pressure roller 9 and the traversing device 8, wherein the traversing device 8 for each winding station 4.1 to 4.4 has a thread guiding in each case in a reciprocating manner. guide wire device. The contact pressure ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com