Slotted magnetic core, coil component using same, and manufacturing method of coil component

A magnetic core and gap technology, which is applied in the manufacture of magnetic cores, coils, inductors with magnetic cores, etc., can solve problems such as limitations and achieve the effect of improving manufacturing efficiency

Inactive Publication Date: 2019-08-09

SHT CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] In the gapless magnetic core proposed in Patent Document 2, there is a problem in that since the inductance and the magnetic saturation current are determined by the characteristics of the magnetic material, a desired range of DC superposition characteristics suitable for various power supply circuits is obtained. restricted

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

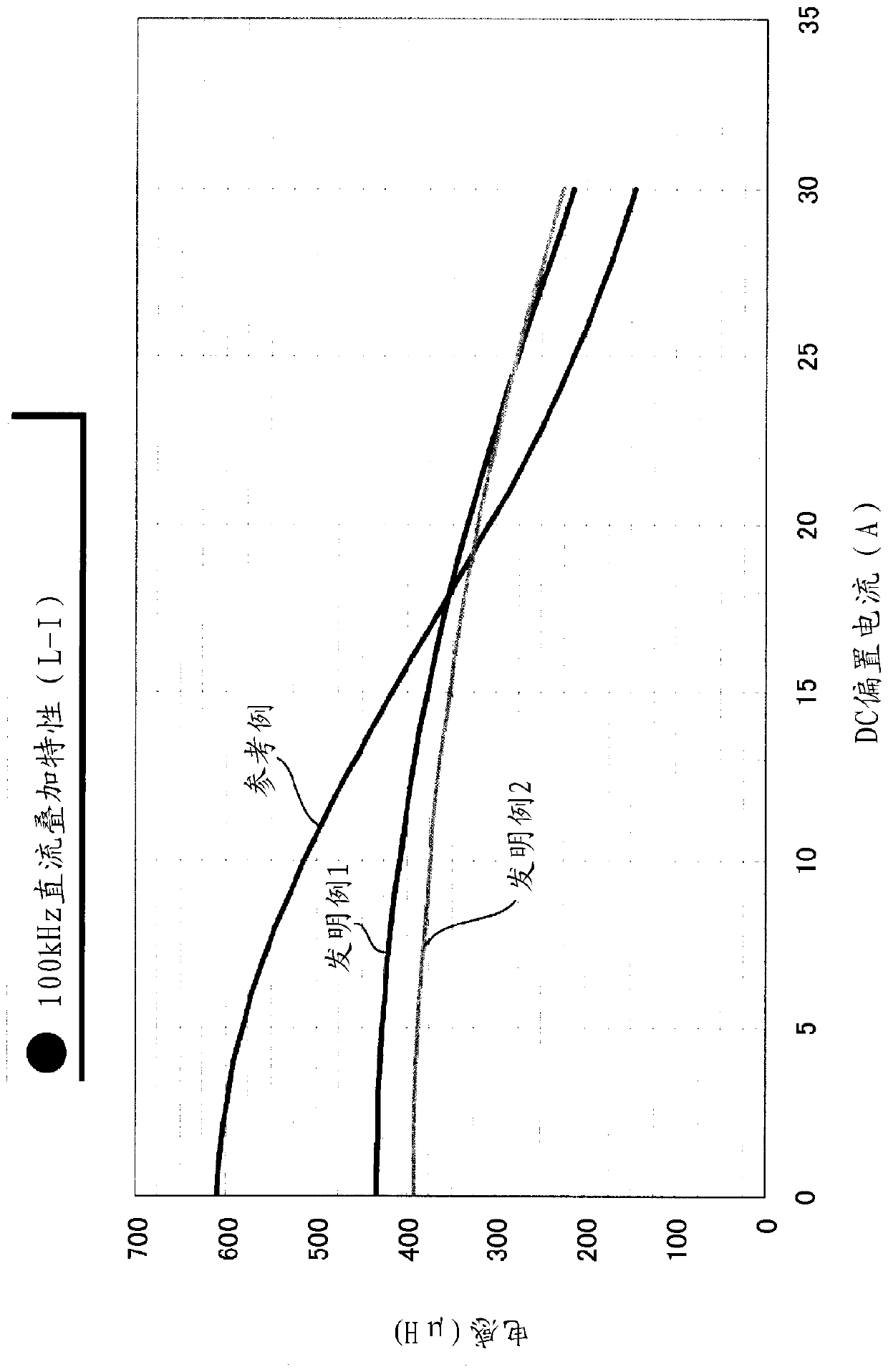

[0119] As the magnetic body 21 , a plurality of powder compacts were produced from Fe—Ni alloy powder, and the molded magnetic core 20 in which the resin coating portion 22 was formed was obtained by insert molding. The magnetic body 21 is annular having a cross section with a width of 9.8 mm and a height of 25 mm, and an outer diameter of 40 mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

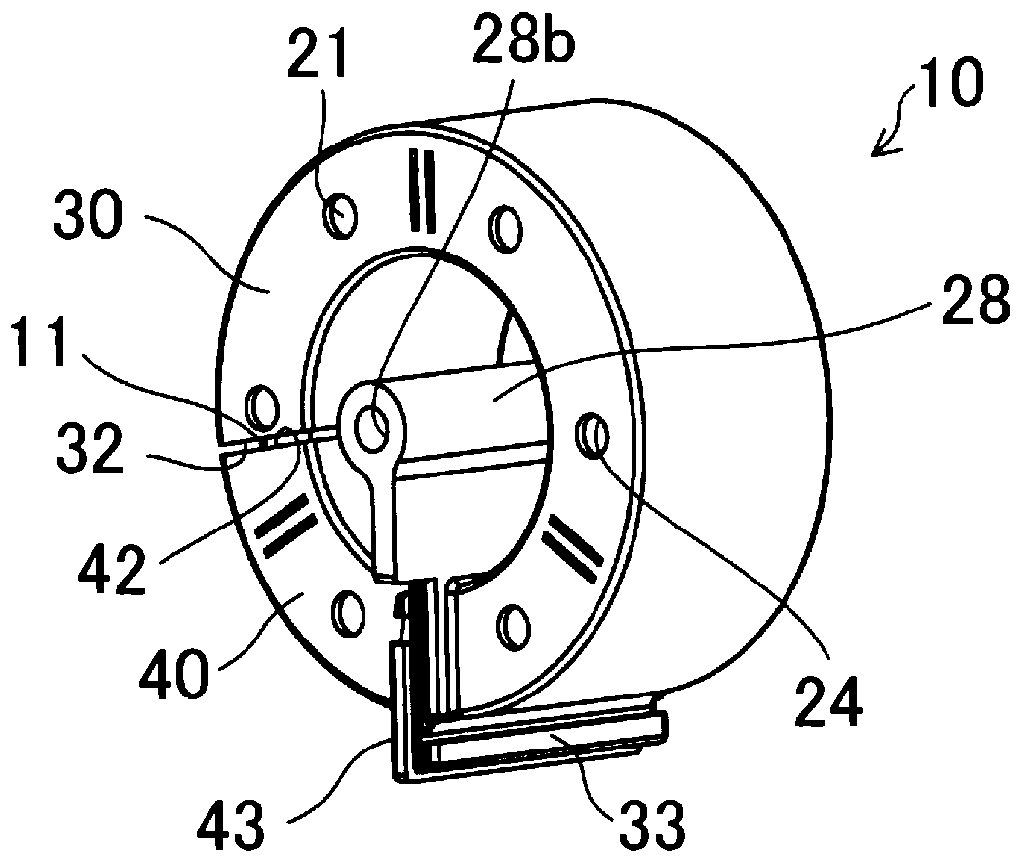

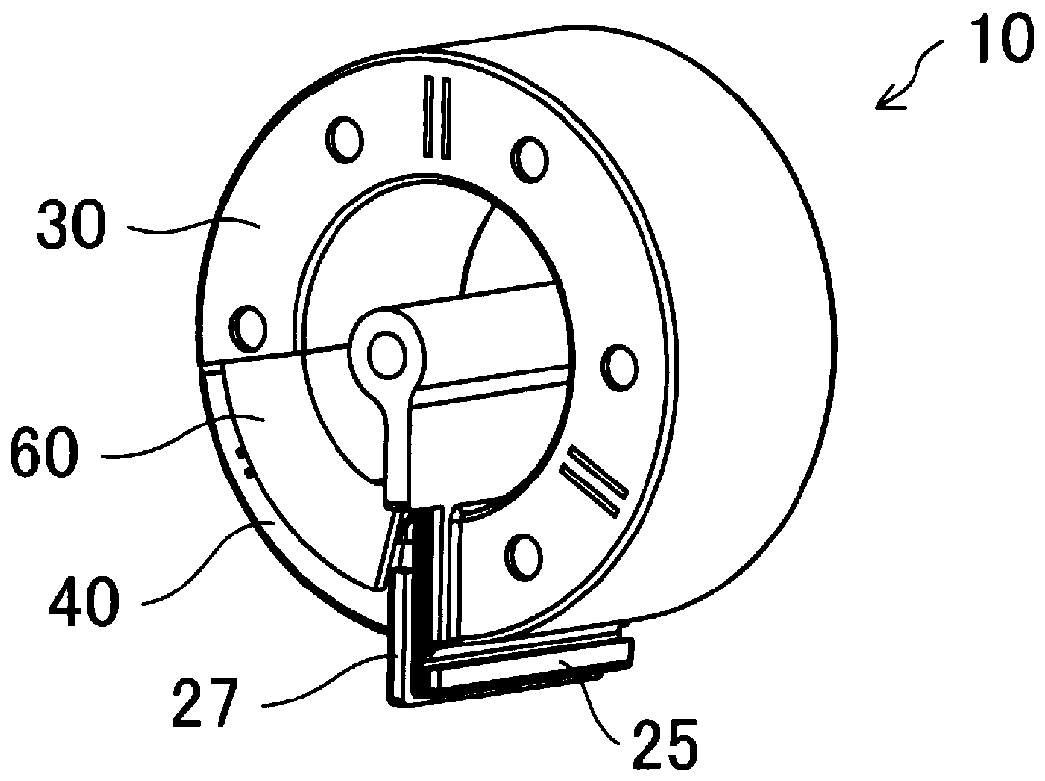

The present invention provides a gapped core that facilitates adjustment of DC bias characteristics, has little variation in those characteristics, and also allows for excellent manufacturing efficiency. A gapped core (10) according to the present invention has a main body (30) and a segment (40) that are obtained by a molded core (20) including an annular magnetic body made of a magnetic material and a resin covering part that covers the magnetic body being cut at a first cutting part and a second cutting part that transect an outer peripheral surface and an inner peripheral surface and approach each other toward an inner periphery of the molded core, the main body (30) having a main body-side first end face formed by cutting at the first cutting part and a main body-side second end face formed by cutting at the second cutting part, and the segment (40) having a segment-side first end face formed by cutting at the first cutting part and a segment-side second end face formed by cutting at the second cutting part, the segment being disposed in a cutout part (31) formed between the main body-side first end face and the main body-side second end face of the main body, and the main body-side first end face and the segment-side first end face and / or the main body-side second end face and the segment-side second end face opposing each other across a gap (11).

Description

technical field [0001] The present invention relates to a magnetic core used for a coil component of a rectifier circuit, a noise prevention circuit, a resonant circuit, etc. equipped in AC equipment such as a power supply circuit and an inverter, a coil component using the core, and a method for manufacturing the coil component. Background technique [0002] A coil device mounted in a circuit of various AC equipment includes a coil component in which a coil is wound around an annular magnetic core. [0003] In order to easily wind the coil on the magnetic core, the following coil components have been proposed. The coil component forms a magnetic core partially formed with a void, inserts a pre-wound air-core coil through the void, and then uses magnetic or a non-magnetic filling material to backfill the gap, using the gap as a gap (for example, refer to Patent Document 1 Figure 10 ). [0004] On the other hand, the applicant proposes a gapless magnetic core in which a rin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): H01F27/24H01F17/06H01F27/255H01F37/00H01F41/02

CPCH01F3/14H01F17/062H01F27/255H01F27/266H01F27/2895H01F27/306H01F37/00H01F41/0206H01F41/0246H01F41/08H01F17/06H01F27/24H01F41/04H01F27/28

Inventor 高桥康臣井上雅文今西恒次吉森平

Owner SHT CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap