Rubbing mechanism and fine dried noodle making machine

A technology of noodle machine and driving mechanism, which is applied in the fields of dough processing, baking, food science, etc., can solve the problems of large floor space and inconvenient maintenance, and achieve the effect of small floor space, reduction of occupational diseases, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

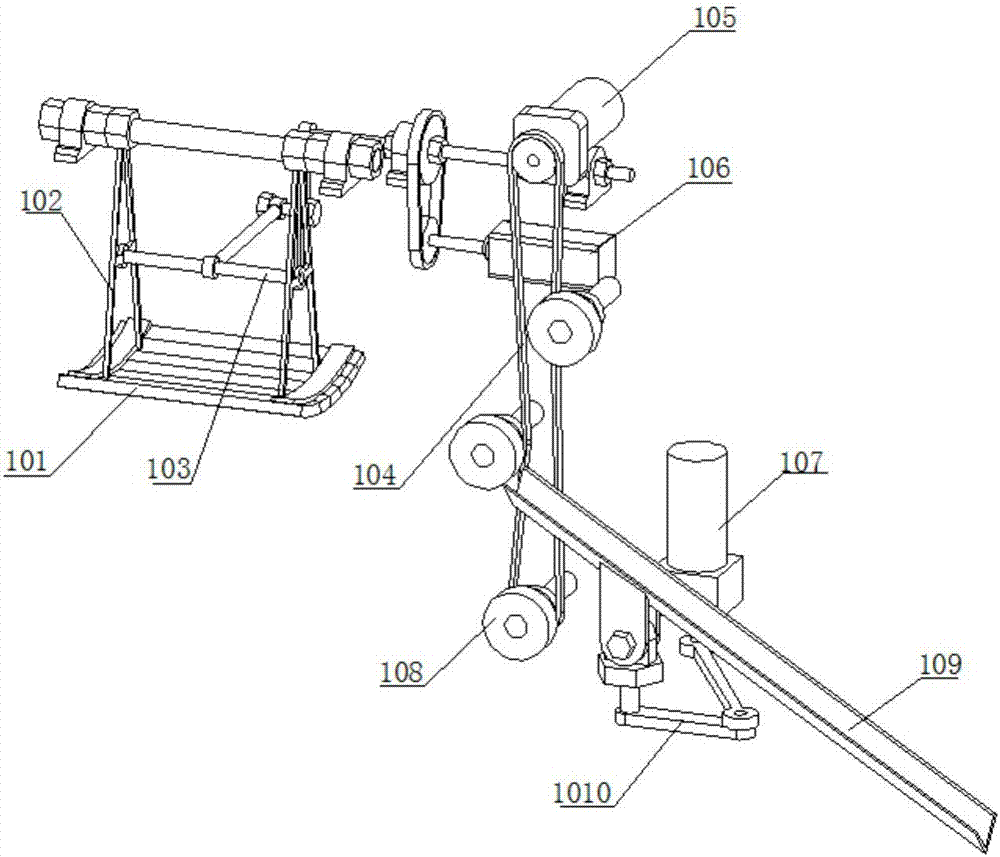

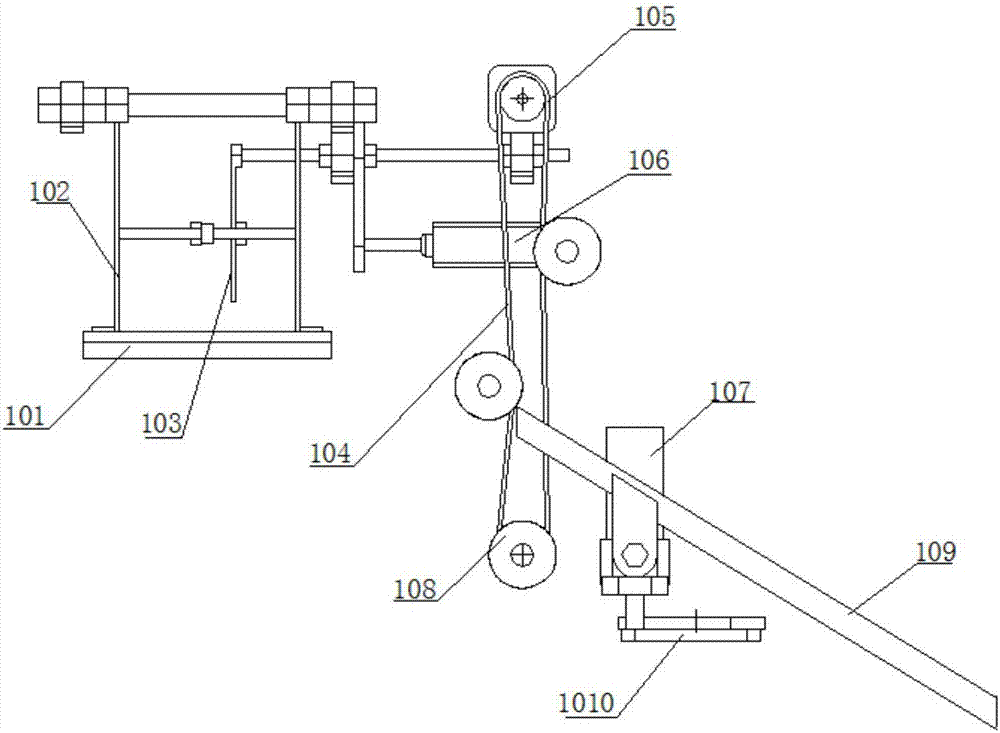

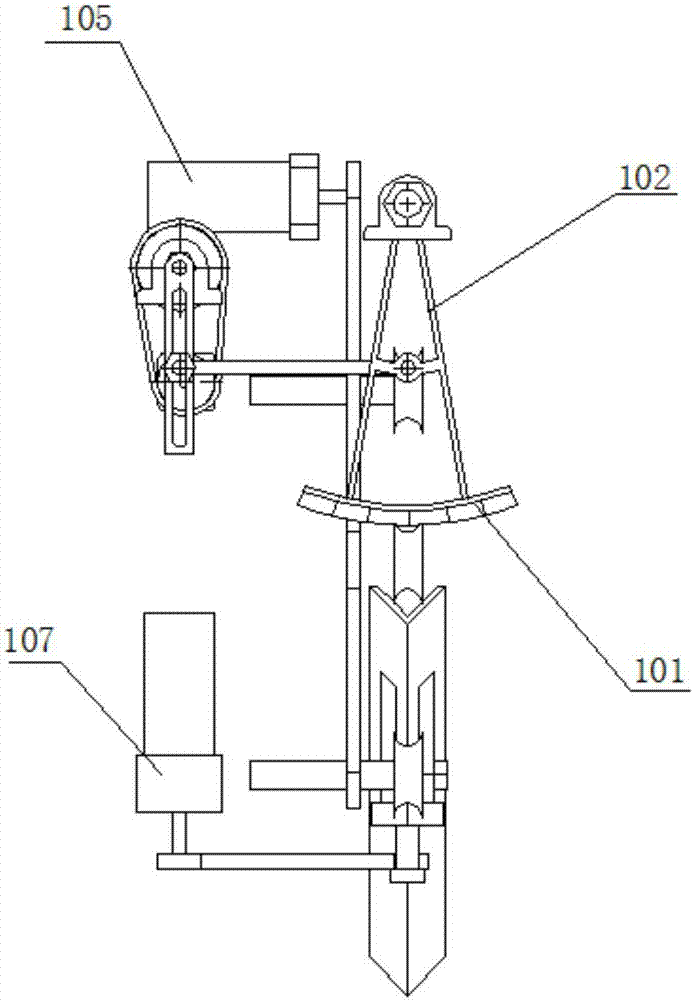

[0044] figure 1 Structural schematic diagram of the rubbing mechanism provided for the embodiment of the present invention; figure 2 The front view of the rubbing mechanism provided by the embodiment of the present invention; image 3 The side view of the rubbing mechanism provided for the embodiment of the present invention;

[0045] Such as Figure 1-3 As shown, the rubbing mechanism provided in this embodiment includes: a washboard 101, a swing body 102 connected to the washboard 101, a first drive mechanism 106 for driving the swing body 102 to swing, a plurality of first guides for conveying noodles Wheel 108 and the second drive mechanism 105 for driving the first guide wheel 108; a plurality of first guide wheels 108 are arranged vertically, which can effectively prevent the noodles from slipping during the stretching process and lose the purpose of stretching. Guide wheel 108 vertical installation can make the contact area of noodle and first guide wheel 108 bigg...

Embodiment 2

[0054] Figure 4 A schematic structural view of the noodle machine provided by the embodiment of the present invention; Figure 5 The front view of the noodle machine provided by the embodiment of the present invention; Figure 6 Schematic diagram of the structure of the disk mechanism of the noodle machine provided by the embodiment of the present invention; Figure 7 The front view of the disk surface mechanism of the noodle machine provided by the embodiment of the present invention; Figure 8 It is a side view of the disk surface mechanism of the noodle machine provided by the embodiment of the present invention.

[0055] Such as Figure 4-8 As shown, the noodle machine provided in this embodiment includes: a frame 700, on which a plurality of conveying bodies arranged sequentially from top to bottom are arranged, and a rubbing mechanism 100 and a disk surface mechanism 200 are also arranged on the frame 700, and The strip mechanism 100 is located on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com