Preparation method of compound liquid bait for artificial cultivation of coral

A compound liquid and artificial technology, applied in animal feed, animal feed, animal husbandry, etc., can solve the problem of high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

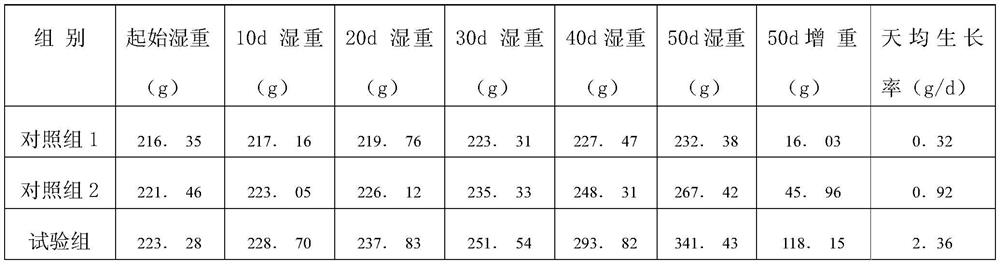

Examples

Embodiment 1

[0049] 1. Preparation of enzymatic hydrolysis liquid and fish oil mixture

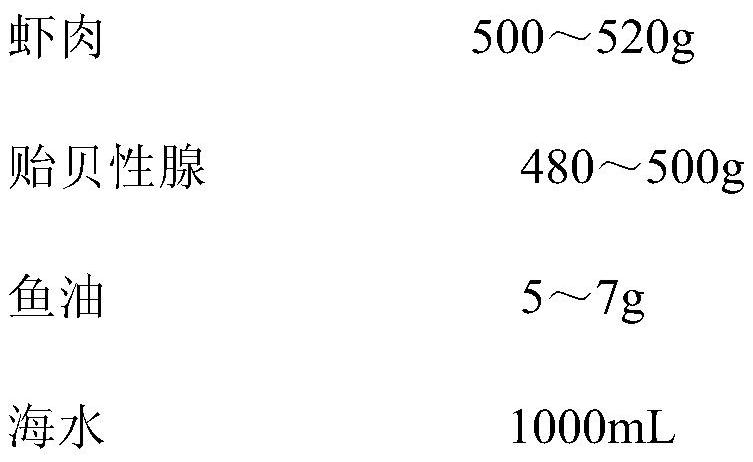

[0050] (1) proportioning by weight and volume:

[0051]

[0052] (2) Preparation:

[0053] Add seawater to the gonads of shrimp meat and mussels, grind them into shrimp meat and mussels gonads by a grinder, add 0.036kg of compound protease for enzymolysis to obtain an enzymatic hydrolysis solution, and pass the enzymatic hydrolysis solution through 200 mesh nylon cloth After filtration, the enzymatic hydrolysis liquid was added; 0.07 kg of fish oil was added to the enzymatic hydrolysis liquid, mixed to make a mixture of the enzymatic hydrolysis liquid and fish oil, and refrigerated at 6°C for later use.

[0054] Described seawater refers to seawater cooled to normal temperature after boiling seawater for 5 minutes.

[0055] The composite protease is composed of acid protease and papain in a weight ratio of 1:1.

[0056] The enzymolysis conditions are as follows: pH is 4.0, enzymolysis temperature...

Embodiment 2

[0077] Example 1

[0078] 1. Preparation of enzymatic hydrolysis liquid and fish oil mixture

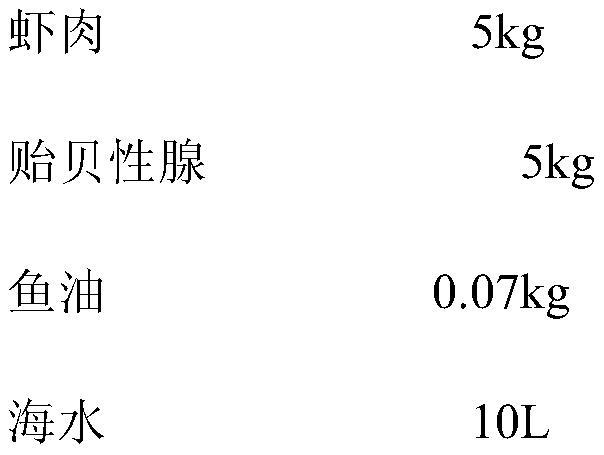

[0079] (1) Proportioning in parts by weight and volume:

[0080]

[0081] (2) Preparation:

[0082] Add seawater to the gonads of shrimp meat and mussels, grind them into shrimp meat and mussels gonads by a grinder, add 0.072kg of compound protease for enzymolysis to obtain an enzymatic hydrolysis solution, and pass the enzymatic hydrolysis solution through 200-mesh nylon cloth After filtration, the enzymatic hydrolysis liquid was added; 0.14 kg of fish oil was added to the enzymatic hydrolysis liquid, mixed to make a mixture of the enzymatic hydrolysis liquid and fish oil, and refrigerated at 6°C for later use.

[0083] Described seawater refers to seawater cooled to normal temperature after boiling seawater for 5 minutes.

[0084] The composite protease is composed of acid protease and papain in a weight ratio of 1:1.

[0085] The enzymolysis conditions are as follows: pH is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com