A comprehensive processing method for bagged black tea snus

A comprehensive processing and snus technology, which is applied in the fields of tobacco, processed tobacco, tea treatment before extraction, etc., can solve the problems of poor mouthfeel quality, high irritation, bitter taste and strong spicy taste of snus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

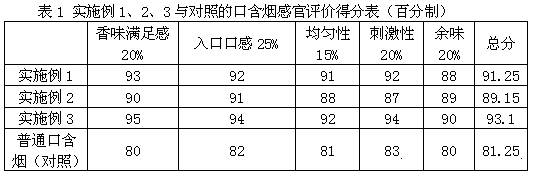

Examples

Embodiment 1

[0024] 1) Collect fresh tea leaves with a tenderness of one bud and two leaves to one bud and three leaves, wither naturally for 15 hours, stop withering when the water content of the leaves is 68%, and then grind the tobacco leaves to a particle size of 20-30 mesh, and wither the leaves Mix the tea leaves;

[0025] 2) Put the mixed withered tea leaves and tobacco powder mixture into the tea rolling machine for kneading treatment. The kneading method is "no pressure → light pressure → heavy pressure → light pressure → no pressure", and the kneading time is 60 minutes ;

[0026] 3) Put the mixture of tea leaves and tobacco powder after kneading into a black tea fermentation machine, and ferment under temperature and humidity control. The fermentation temperature range is 28°C, the fermentation relative humidity range is 95%, and the fermentation time range is 7h;

[0027] 4) The fermented tea and tobacco mixture is subjected to the first heat treatment, the heat treatment temp...

Embodiment 2

[0032] 1) Collect fresh tea leaves with a tenderness of one bud and two leaves to one bud and three leaves, wither naturally for 13 hours, stop withering when the water content of the leaves is 69%, and then grind the tobacco leaves to a particle size of 18-35 mesh, and wither the withered leaves Mix the tea leaves;

[0033] 2) Put the mixed withered tea leaves and tobacco powder mixture into the tea rolling machine for kneading treatment. The kneading method is "no pressure→light pressure→heavy pressure→light pressure→no pressure", and the kneading time is 45min ;

[0034] 3) Put the mixture of tea leaves and tobacco powder after kneading into a black tea fermenter, and ferment under temperature and humidity control. The fermentation temperature range is 26°C, the relative humidity range is 90%, and the fermentation time range is 5.5 hours;

[0035] 4) The fermented tea and tobacco powder mixture is subjected to the first heat treatment, the heat treatment temperature range ...

Embodiment 3

[0040] 1) Collect fresh tea leaves with tenderness of one bud and two leaves to one bud and three leaves, wither naturally for 15 hours, and stop withering until the water content of the leaves is 68%, and then grind the tobacco leaves to a particle size of 22-40 mesh, and wither the withered leaves Mix the tea leaves;

[0041] 2) Put the mixture of withered tea leaves and tobacco powder into the tea rolling machine for kneading treatment. The kneading method is "no pressure → light pressure → heavy pressure → light pressure → no pressure", and the kneading time is 65 minutes ;

[0042] 3) Put the mixture of tea leaves and tobacco powder after kneading into a black tea fermenter, and ferment under temperature and humidity control. The fermentation temperature range is 29°C, the relative humidity range is 95%, and the fermentation time range is 7.5 hours;

[0043] 4) The fermented tea and tobacco mixture is subjected to the first heat treatment, the heat treatment temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com