Liquid separation equipment

A technology of liquid separation and equipment, applied in the field of separation, can solve problems such as poor separation effect, and achieve the effect of simple structure, good separation effect and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

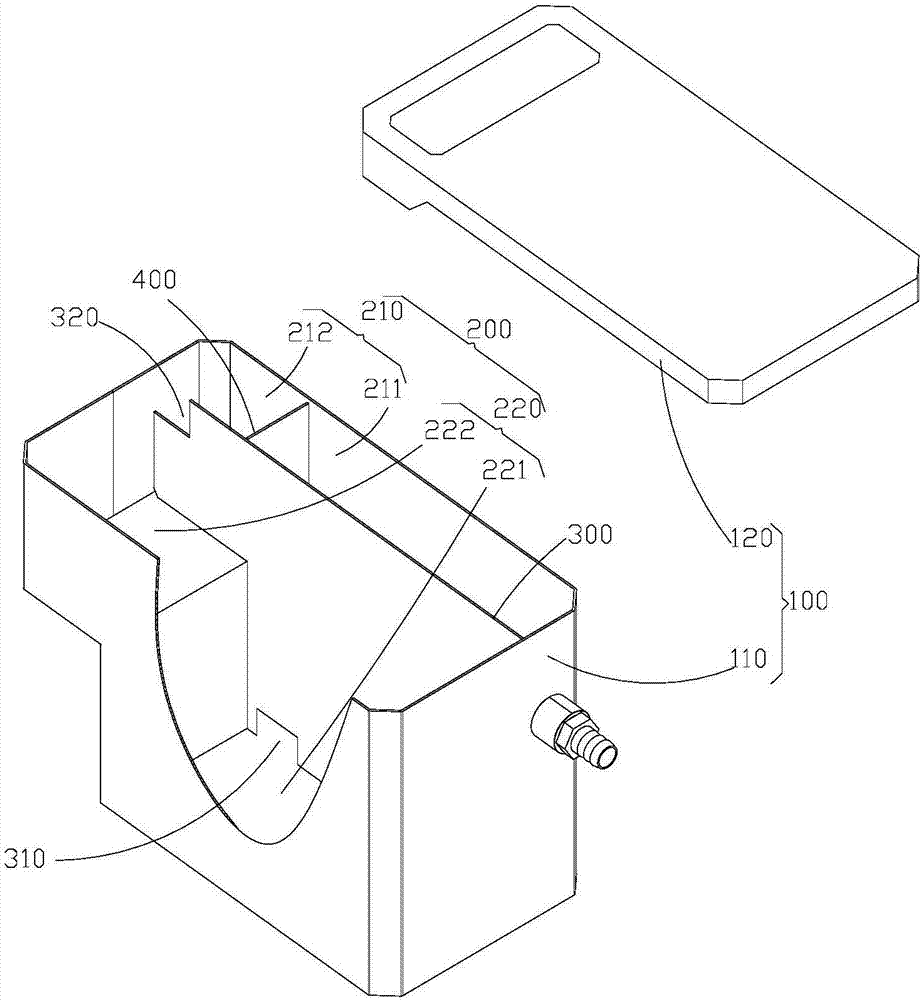

[0031] The present invention provides a liquid separation device, including a liquid separation box 100 , through a reasonable layout of each chamber inside the liquid separation box 100 , to achieve the purpose of improving the liquid separation effect.

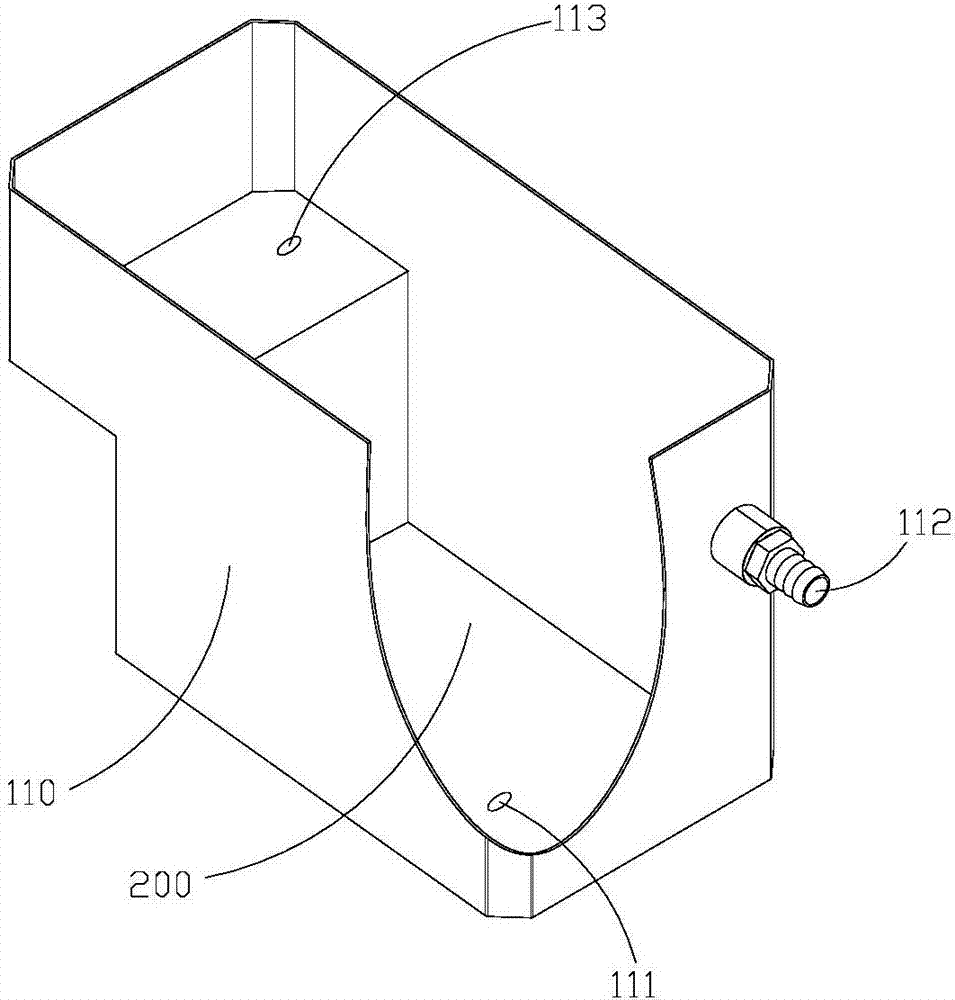

[0032] Such as figure 1 As shown, the liquid separation box 100 includes a box body 110 and a box cover 120 , the box body 110 forms a liquid containing chamber 200 with an open upper end, and the box body 110 can be sealed after the box cover 120 is closed on the box body 110 .

[0033] The liquid-holding chamber 200 is provided with a transverse partition 300, and the upper edge of the transverse partition 300 is flush with the upper edge of the box body 110. The transverse partition 300 divides the liquid-containing chamber 200 into two chambers, and the two chambers are located at The first liquid chamber 210 at the rear side and the second liquid chamber 220 at the front side. The first liquid containing chamber 210 is...

Embodiment 2

[0042] The liquid separation equipment provided by the embodiment of the present invention has the same realization principle and technical effect as the foregoing method embodiment. For the sake of brief description, for the parts not mentioned in the device embodiment, please refer to the corresponding method in the foregoing method embodiment. content.

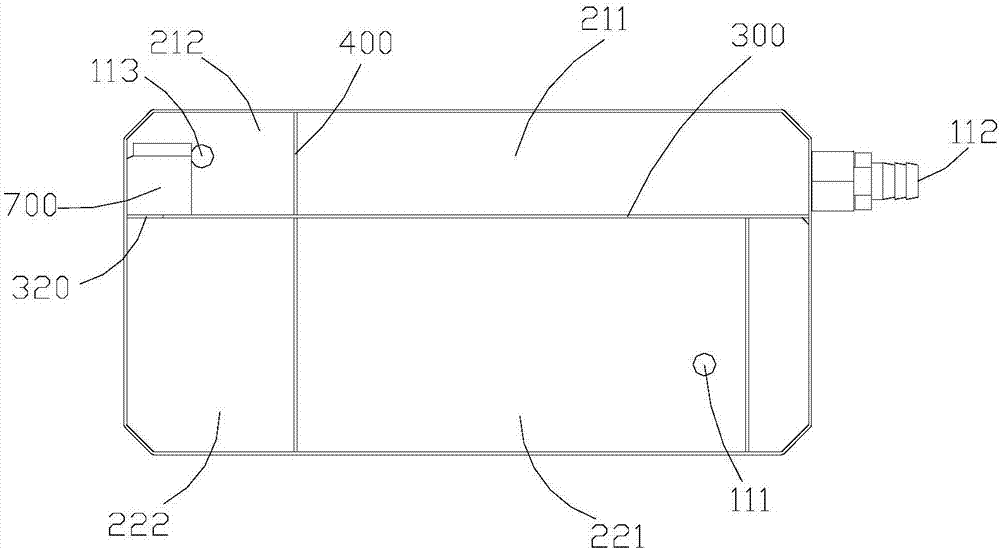

[0043] In the above-mentioned embodiment, in order to ensure that the actions of discharging the second liquid and the first liquid are carried out at the same time, the height of the second liquid outlet 320 and the height of the first liquid outlet hole 112 should have a certain correlation, that is, when the liquid separation box 100 is horizontal When placed, the second liquid outlet 320 and the first liquid outlet 112 should be located at the same height. Therefore, the liquid separation box 100 needs to be leveled before use to avoid a height difference between the second liquid outlet 320 and the first liquid outlet ...

Embodiment 3

[0051] The difference between this embodiment and embodiment 2 is that, as Figure 6 As shown, the liquid separation chamber 221 is provided with a liquid separator 2213 arranged longitudinally, and the height of the liquid separator 2213 is flush with the bottom wall of the left half of the liquid separation box 100 . The liquid separator 2213 divides the liquid separation chamber 221 into a dynamic chamber 2212 and a static chamber 2211 , the dynamic chamber 2212 is farther away from the liquid floating chamber 222 than the static chamber 2211 , and the liquid inlet hole 111 communicates with the dynamic chamber 2212 .

[0052] Such as Figure 7 As shown, the liquid separator 2213 is a rectangular structure, and two liquid outlets 2214 are provided at the bottom thereof. The dynamic cavity 2212 communicates with the static cavity 2211 through the liquid outlet 2214 . The waste liquid to be separated enters the dynamic chamber 2212 through the liquid inlet hole 111, and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap