Constant temperature sample injection adiabatic confluence device

A constant temperature and sample injection technology, which is applied to heating or cooling equipment, laboratory containers, chemical instruments and methods, etc., to achieve the effects of not easy to leak, reduce errors, and have a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is combined with the following combined examples to illustrate the content of the present invention, but not to limit the scope of the present invention.

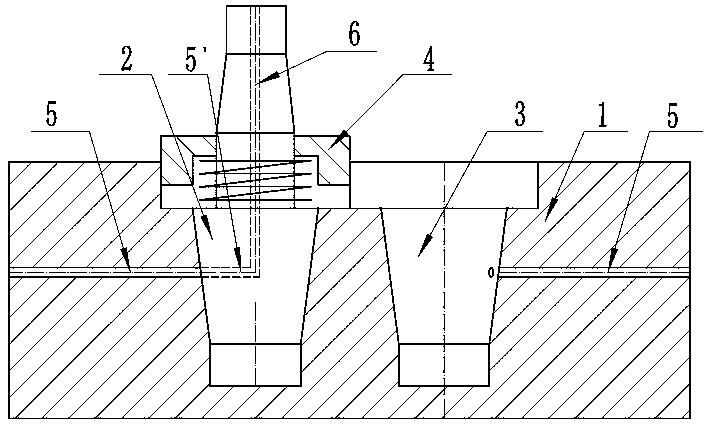

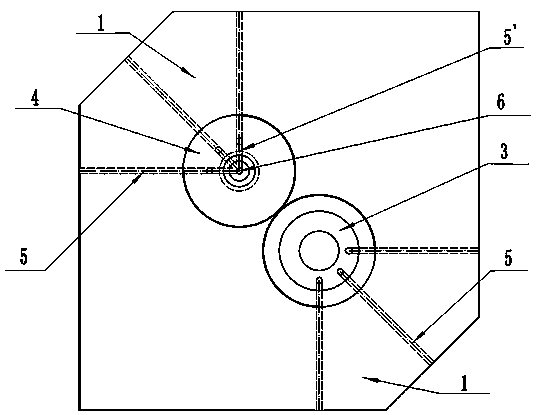

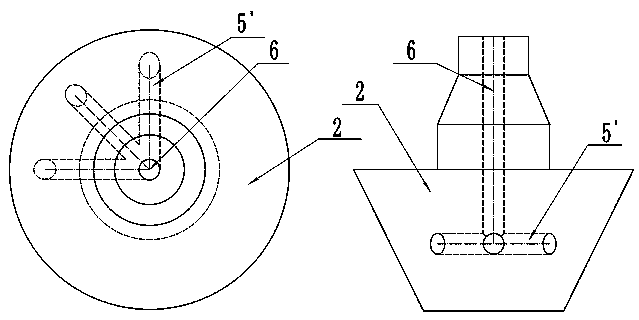

[0020] Such as figure 1 with figure 2 As shown, the thermostatic sample injection adiabatic confluence device is composed of a thermostatic body 1, a thermally insulating tapered cock 2 and a gland 4. The thermostatic body 1 is a polygonal stainless steel metal block. The temperature of the bottom of the thermostatic body 1 is controlled by a semiconductor heating / cooling device. Constant temperature, the constant temperature body 1 has a tapered plug hole 3 that matches the heat insulating tapered cock 2, the heat insulating tapered cock 2 is pressed by the gland 4 by spring force and held in the tapered plug hole 3, the heat insulating cone A semi-cylindrical and semi-conical protrusion is arranged on the upper part of the shaped cock 2, and the structure is as follows: image 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com