A small temperature difference measuring device

A measuring device and small temperature difference technology, applied in the direction of material thermal development, etc., to achieve good adaptability, good compactness, and reduce errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is combined with the following combined examples to illustrate the content of the present invention, but not to limit the scope of the present invention.

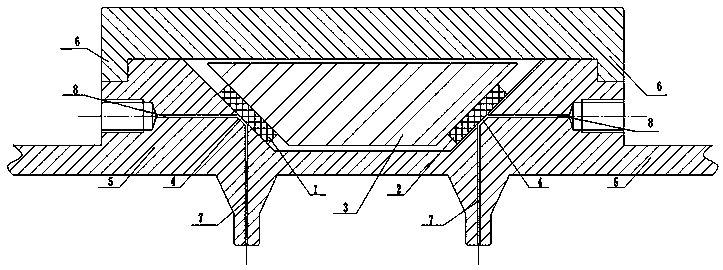

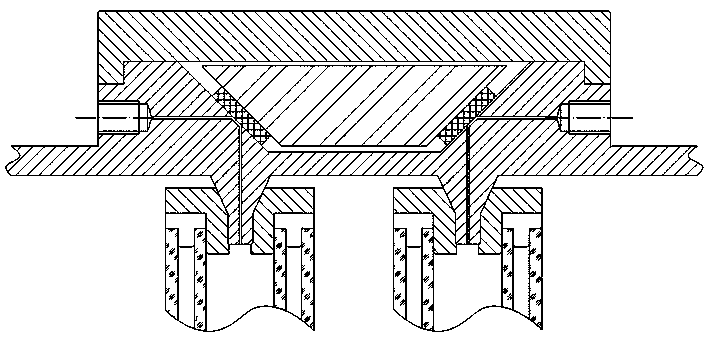

[0014] Such as figure 1 As shown, the small temperature difference measuring device is composed of thermal sensor A1, thermal sensor B2, constant temperature heat sink 3, temperature sensing cavity 4, thermal insulation support body 5, thermal insulation gland 6 inflow channel 7 and outflow channel 8, thermal sensor A1 And the thermal sensor B2 is a twin thermal sensor, using a sheet-like thermopile with the same performance and structure. There are pits on the thermal insulation support 5 for built-in thermal sensor A1, thermal sensor B2 and constant temperature heat sink 3, thermal sensor A1 and thermal sensor The hot end surface of the sensor B2 is in close contact with the side of the constant temperature heat sink 3, and heat-conducting silicone grease is applied to reduce the contact therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com