Mixing and stirring method for modified engineering soil

一种混合搅拌、工程土的技术,应用在黏土搅拌装置、混合操作控制、水泥搅拌装置等方向,能够解决原料浪费等问题,达到改性效果好、好输料效果、使用方便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

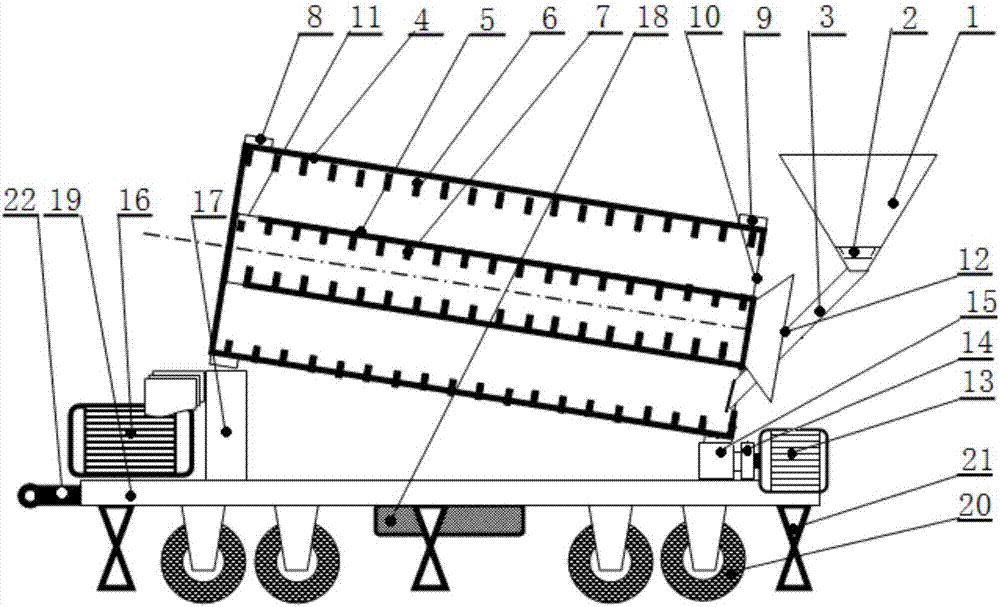

[0032] combine figure 1 and figure 2 , a mobile modified engineering soil mixing device of the present embodiment is mainly composed of a carrying trailer 19, a stirring mechanism and a driving mechanism, and the stirring mechanism and the driving mechanism are both arranged on the carrying trailer 19. A balance support 21 is arranged at the front, middle and rear positions of the transport trailer 19, and the balance support 21 is symmetrically arranged on both sides of the transport trailer 19. During the movement of the transport trailer 19 through the wheels 20, the balance support 21 is in a contracted state. During work, The balance support 21 is supported on the construction ground, making it more stable and not easy to shake during work. One end of the carrying trailer 19 is provided with a supporting hook 22 to facilitate pulling and carrying the carrying trailer 19 .

[0033] The mixing mechanism in this embodiment includes an outer mixing drum 4, an inner mixing ...

Embodiment 2

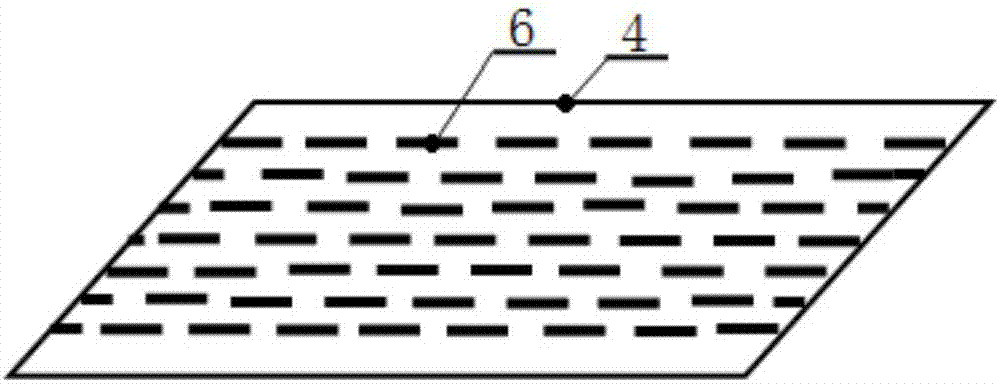

[0040] A mobile modified engineering soil mixing device of this embodiment has the same basic structure as that of Embodiment 1, the difference being that in this embodiment, the non-continuous spiral stirring blades 6 arranged on the inner wall of the outer mixing drum 4 are arranged in a cross arrangement , the spiral stirring blades 6 between the middle part of the outer mixing drum 4 and the lower end of the outer mixing drum 4 are arranged at equal intervals, and the distance between the spiral stirring blades 6 from the middle part of the outer mixing drum 4 to the upper end of the outer mixing drum 4 gradually becomes smaller, that is, the spiral stirring The arrangement of the blades 6 is finer and has a better pulverizing effect. At the same time, it can increase the friction between the outer mixing drum 4 and the materials, and has a greater lifting force, and accelerates the materials entering the feeding port 11 of the inner mixing drum. The inclination of the set ...

Embodiment 3

[0042] A mobile modified engineering soil stirring device of this embodiment has the same basic structure as that of Embodiment 1, the difference is that in this embodiment, the inner wall of the inner mixing drum 5 is provided with two continuous spiral stirring fins 7 , forming a double-screw conveying structure, which can speed up material conveying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com