Tape box and tape printing system

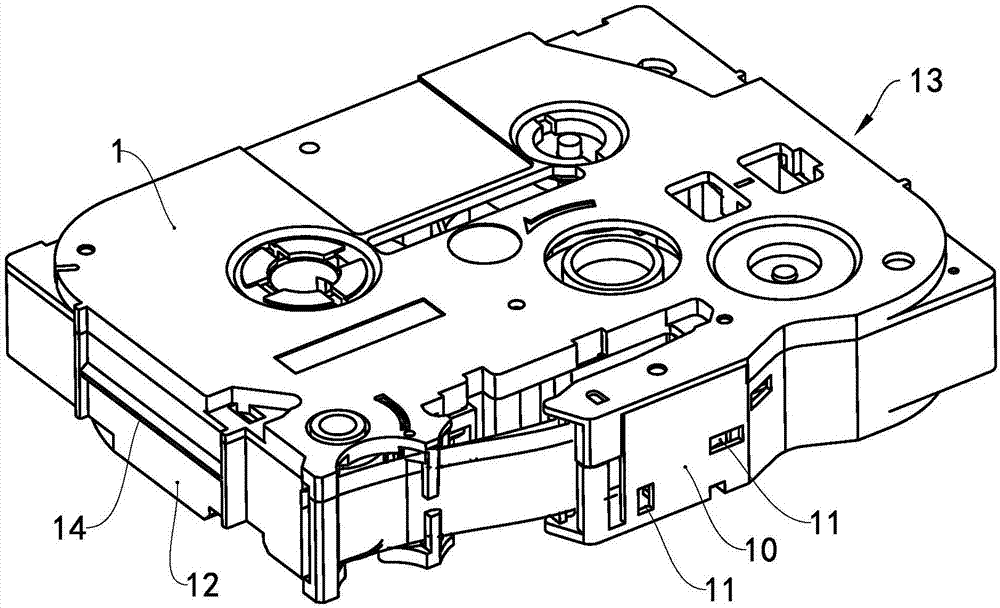

A technology of a printing system and a tape printer, which is applied to ink ribbon boxes, printing devices, printing, etc., can solve the problems that positioning ribs 14 are easily stuck in the tape printer and have poor versatility, so as to improve compatibility and versatility , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

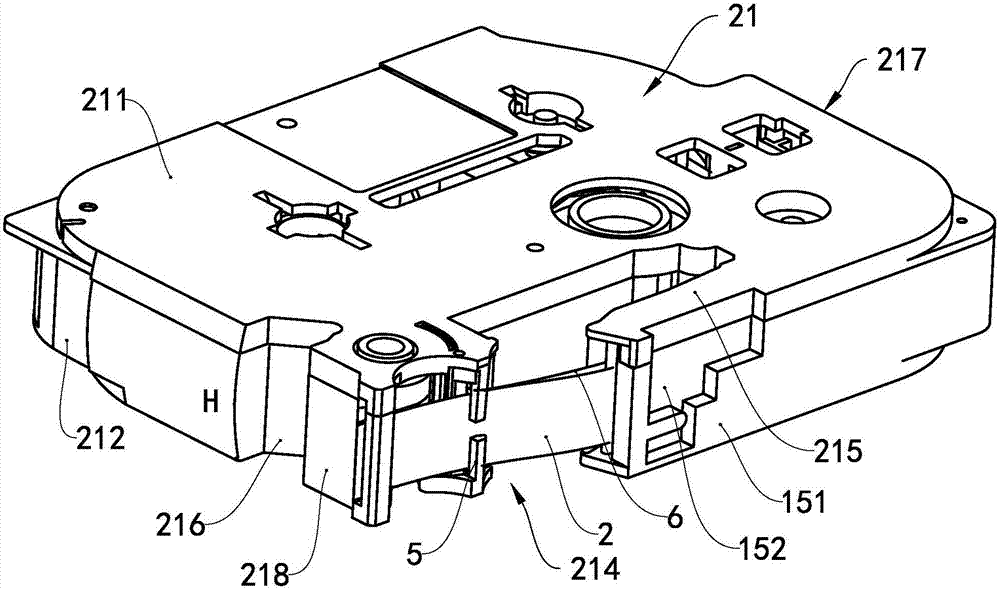

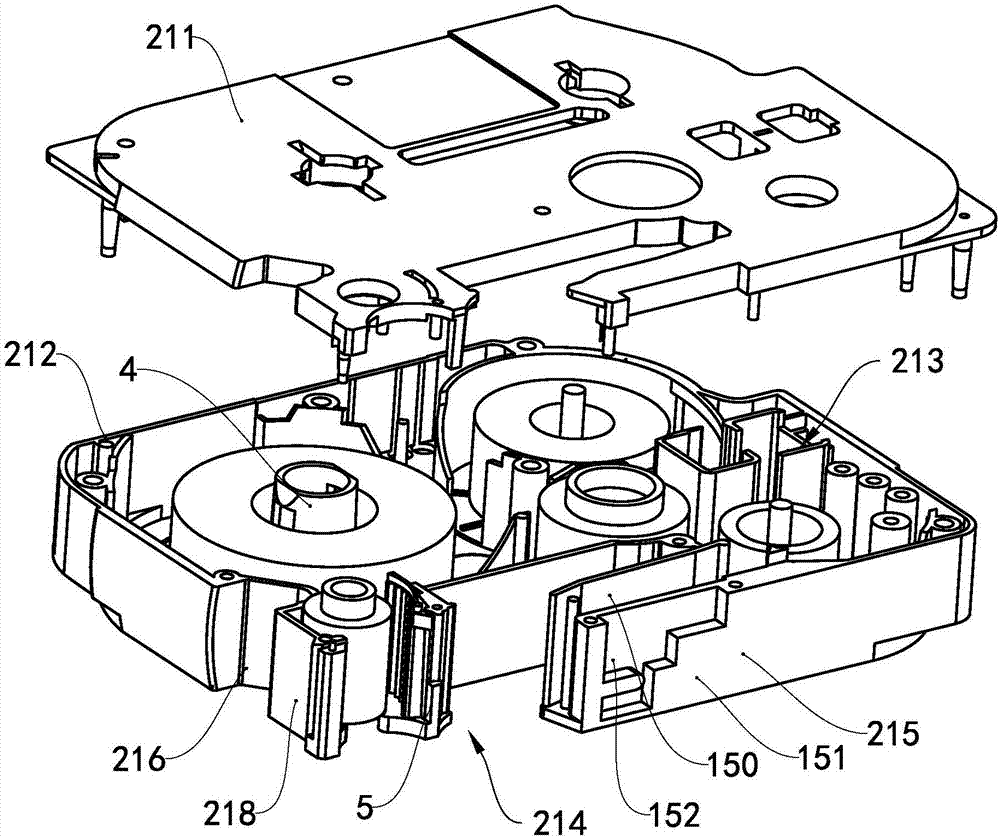

[0018] see figure 2 and image 3 , the tape printing system of the present embodiment includes a tape printer and a tape cassette detachably installed on the tape printer, the tape printer includes a cassette accommodating part, a detecting part, a printing device and a cutting mechanism, etc., and the detecting part has multiple a detection switch. The tape cassette is installed in the cassette accommodating part, and the tape cassette includes a housing 21, an ink ribbon 2, an ink ribbon 6 and an ink ribbon drive roller 4, and the housing 21 includes an upper housing 211 and a lower housing 212, and the upper housing 211 and the lower housing The body 212 encloses a ribbon accommodating cavity 213 , and the ribbon 2 , ink ribbon 6 and the ink ribbon driving roller 4 are arranged in the ribbon accommodating cavity 213 , and the ink ribbon 6 is driven by the ink ribbon driving roller 4 and supplied along a predetermined supply path.

[0019] The housing 21 has a tape outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com