Model based on cross-layer shuttle vehicle intensive automatic storage system and optimization method of model

A technology of automatic storage and optimization method, which is applied in the direction of storage device, transportation and packaging, etc., and can solve problems such as modeling and optimization of outbound operations that are not applicable to the intensive automatic storage system of cross-floor shuttle vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

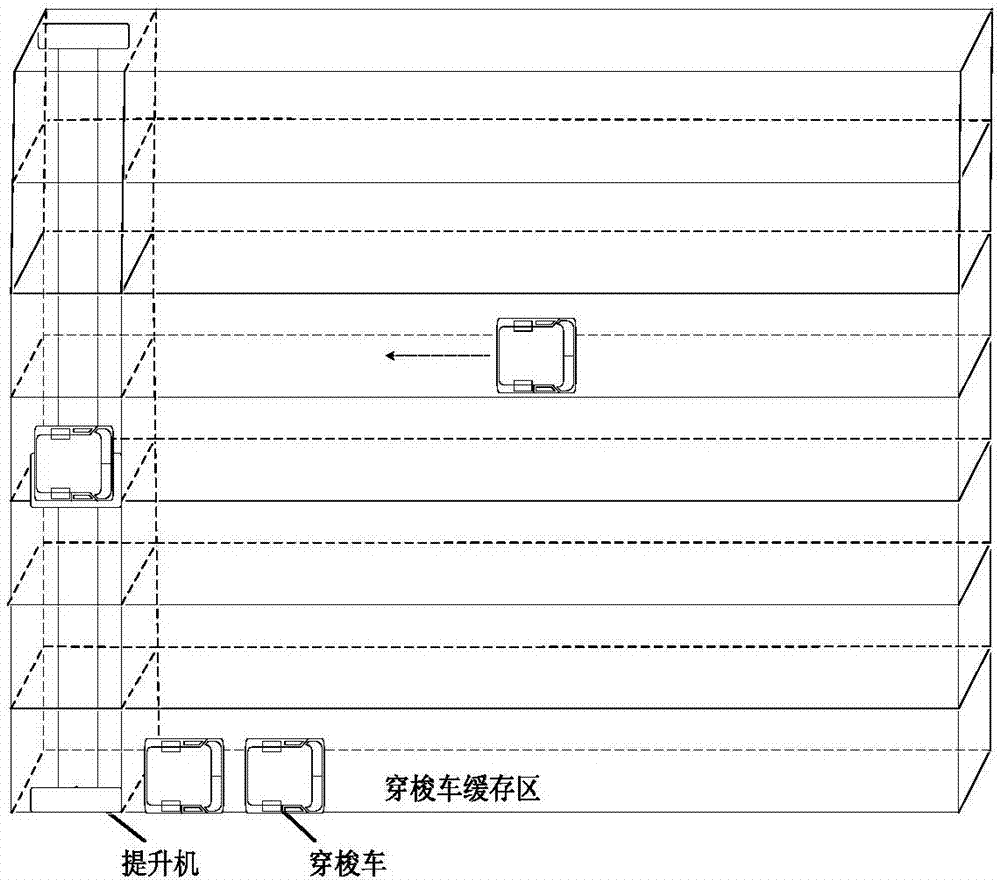

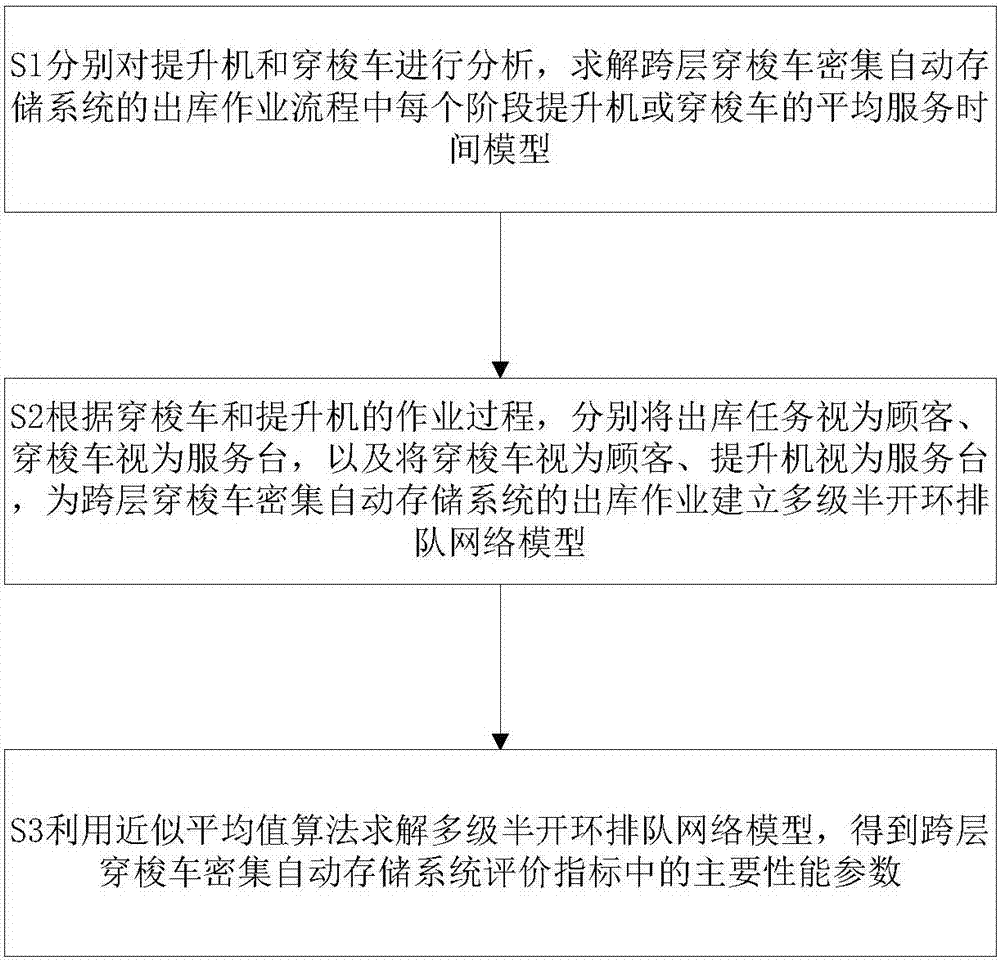

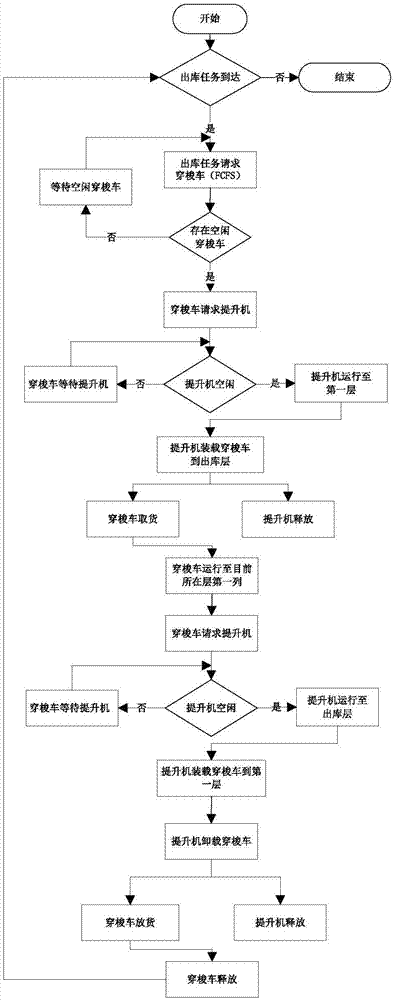

Embodiment 1

[0084] As introduced in the background technology, there is a problem in the prior art that the modeling method of the traditional three-dimensional warehouse is not suitable for the modeling optimization of the outbound operation of the intensive automatic storage system of the cross-floor shuttle, and how to evaluate the intensive automatic storage of the cross-floor shuttle. The problem of storage system performance provides a model and optimization method for a dense automatic storage system based on cross-layer shuttle vehicles. The invention establishes a queuing network model to accurately simulate the actual outbound task process based on the intensive automatic storage system of cross-layer shuttle vehicles, and quickly estimates the performance of the intensive automatic storage system based on cross-layer shuttle vehicles under various shelf and equipment configurations. Provide decision support for the optimal design of the dense automatic storage system for cross-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com