Turnover unloading device

An unloading device and tipping technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of low unloading efficiency, high safety hazards and high labor costs, achieve high unloading efficiency, improve quality and speed, The effect of reducing the risk of unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

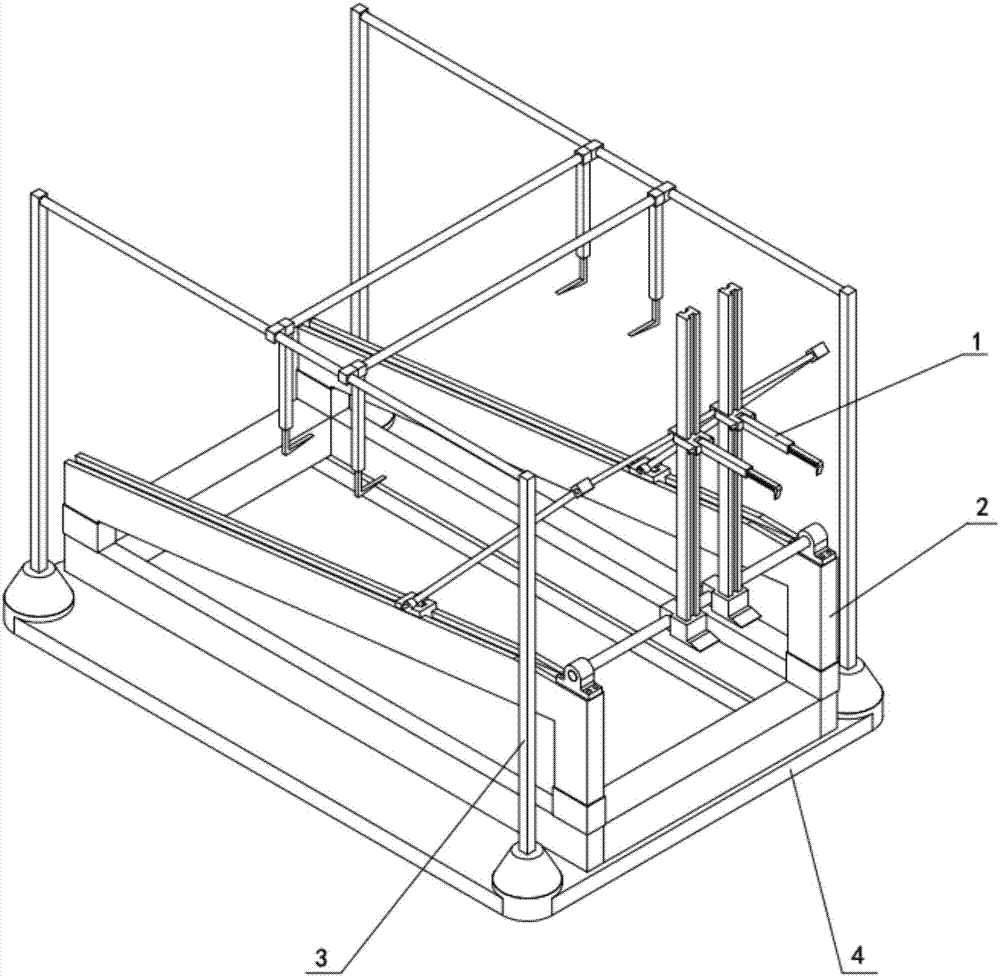

[0031] Such as Figure 1-Figure 13 As shown, an overturning and unloading device in this embodiment includes a positioning and engaging mechanism 1, an overturning mechanism 2, a gantry mechanism 3, and a walking mechanism 4. The positioning and engaging mechanism 1 is used for roughly lifting, occluding, and Positioning, the overturning mechanism 2 is used to turn the positioning and engaging mechanism 1 and its lifted goods to a horizontal position, the gantry mechanism 3 is used to transfer the goods to another position, and the walking mechanism 4 For moving and fixing the whole unit.

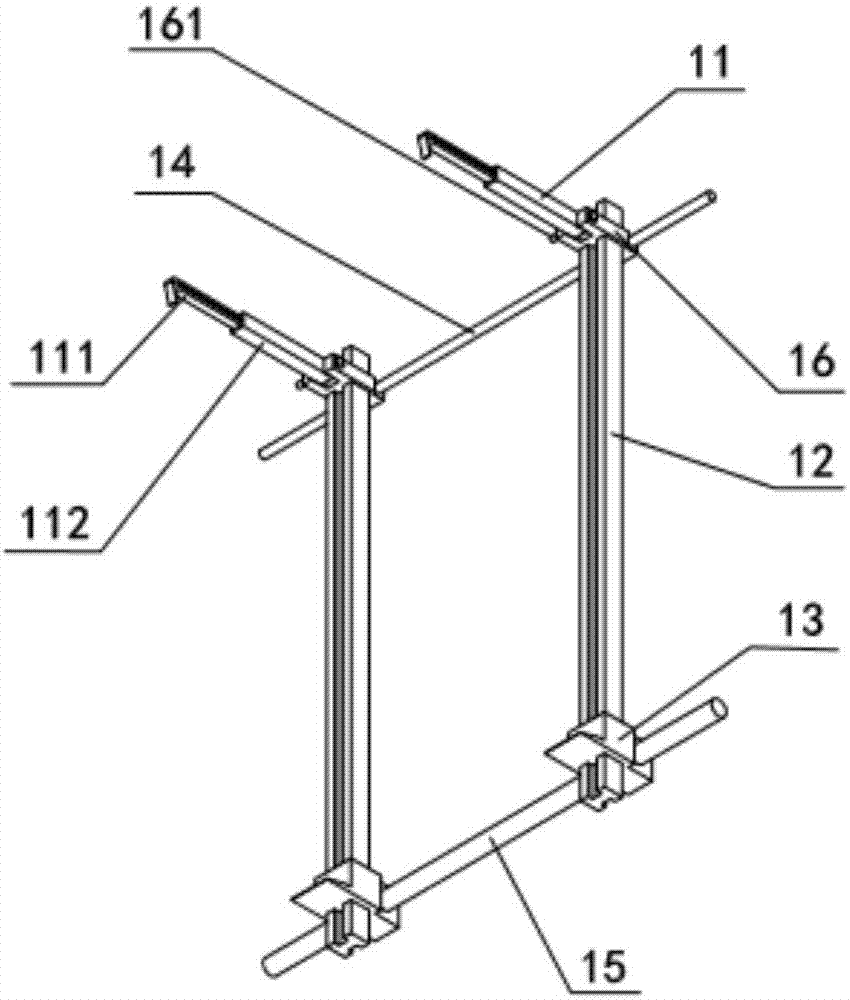

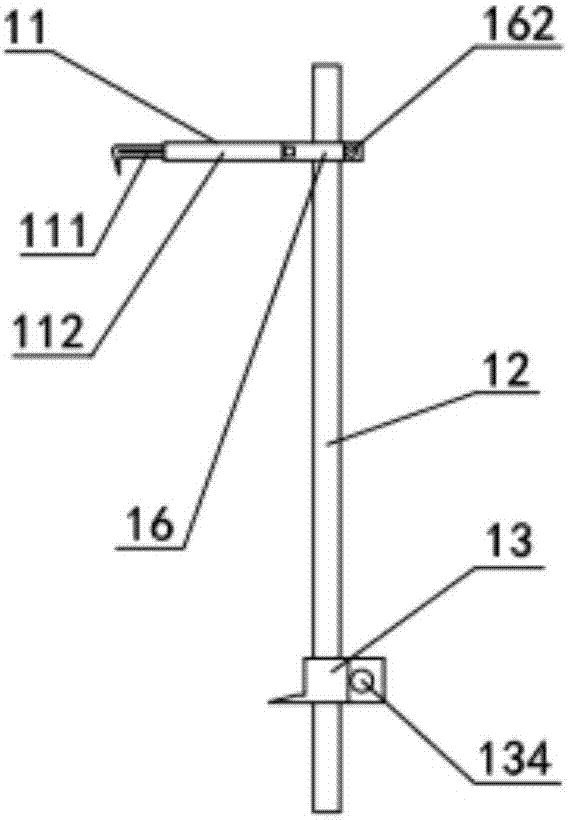

[0032] The positioning and engaging mechanism 1 includes two engaging hooks 11, two supporting frames 12, two probing teeth 13, a longitudinally moving beam 14, and a fixed fulcrum beam 15. The engaging hook 11 includes a hook tooth main body 111, The main body sleeve 112, the main body sleeve 112 covers a part of the hook tooth main body 111, the length of the hook tooth main body 111 exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com