Troffer keel and mortar smearing processing structure

A lamp trough and keel technology, which is applied in the field of decoration, can solve the problems of burr, inconvenient cleaning and sanitation, and unstable structure of gypsum decorative strips, and achieve the effect of improving the decoration effect, the lamp trough is clean, and the later cleaning is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

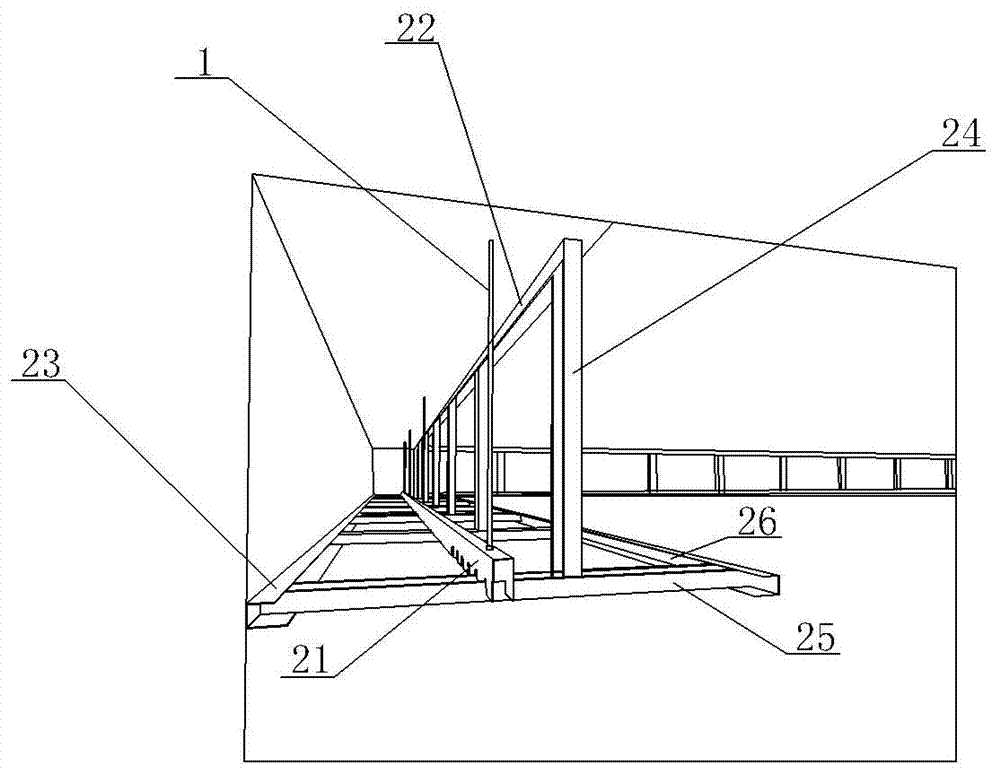

[0013] Embodiment one: if Figure 1-3 As shown, the present invention is a light trough keel and fan ash treatment structure, including a suspender 1, a light steel keel structure and a light trough box made of wooden boards. The all light steel keel structure includes a main keel fixed at the bottom of the suspender 1 21. The first side keel 22 fixed on the ceiling, the second side keel 23 fixed on the wall, the third side keel 26, a plurality of drooping vertical sub-keels 24 and the horizontal ones vertically fixed on the lower part of the vertical sub-keel 24 The keel 25, the upper part of the vertical secondary keel 24 is fixed on the first side keel 22, the inner end of the horizontal secondary keel 25 is connected with the second side keel 23, the middle part of the horizontal secondary keel 25 is connected with the main keel 21, and the outer end of the horizontal secondary keel 25 is connected with the second side keel 26 connections on three side keels.

[0014] The...

Embodiment 2

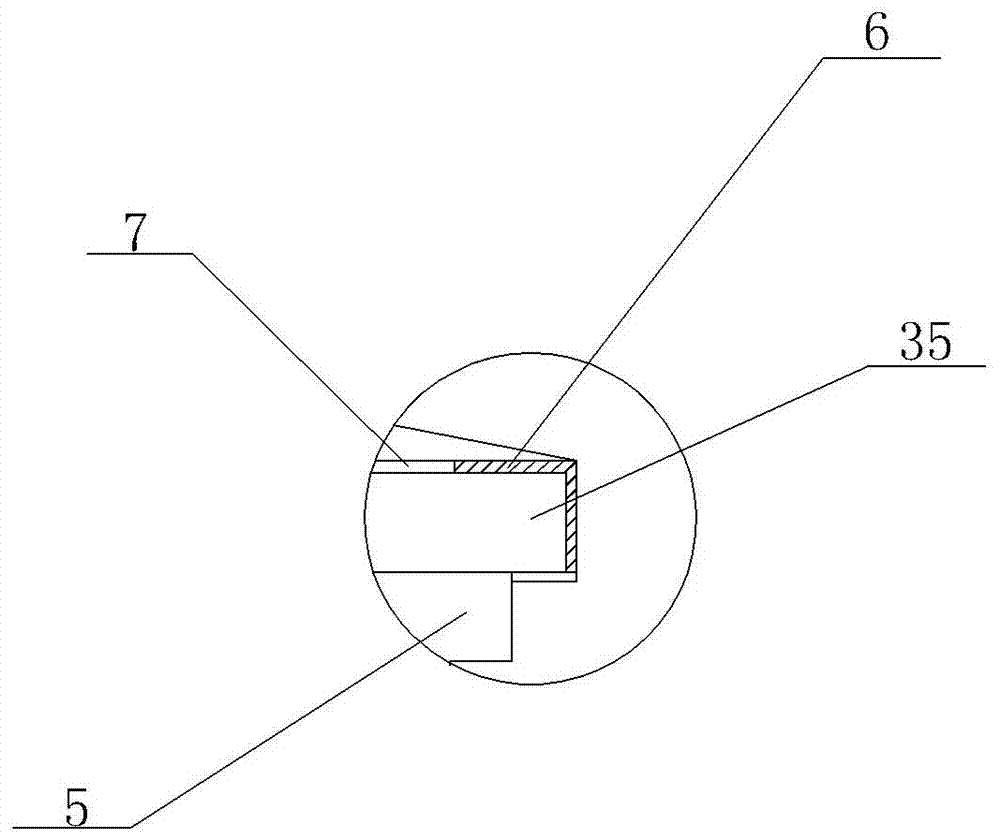

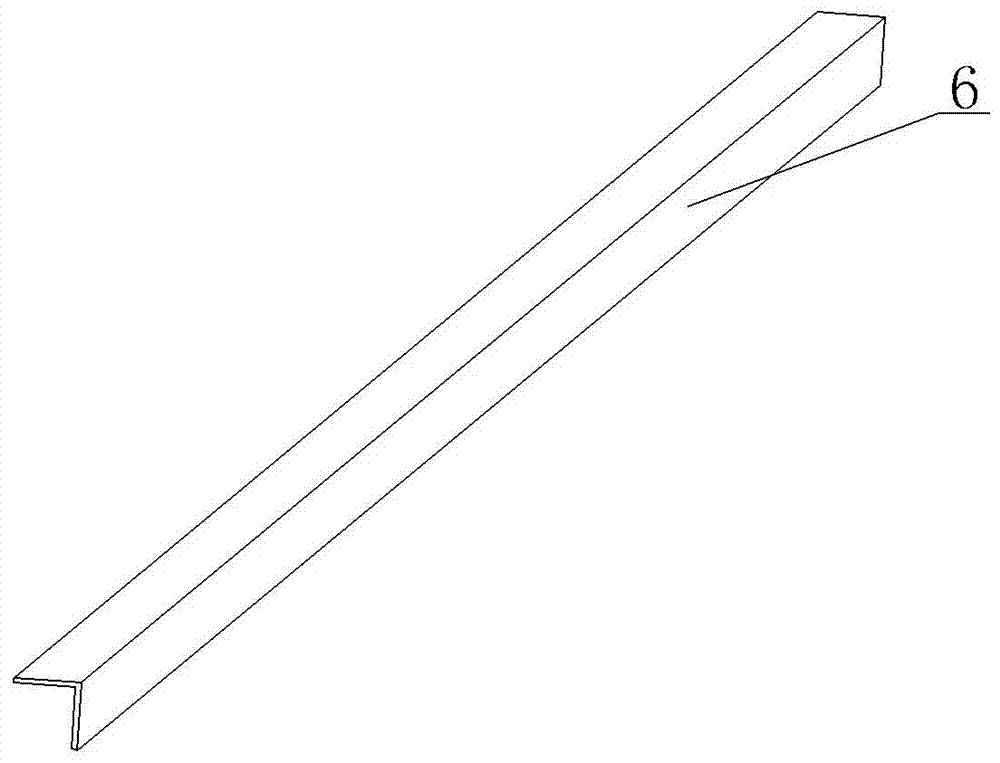

[0017] Embodiment 2. In Embodiment 1, the male corner strip 6 is changed to cover the lower right angle of the flat convex section 35 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com