Method for preparing mandibular angle osteotomy guide plates on basis of 3D (three-dimensional) printing

A 3D printing and mandibular technology, applied in bone drill guidance, medical science, computer-aided planning/modeling, etc., can solve problems such as nerve injury, narrow surgical field of view, and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

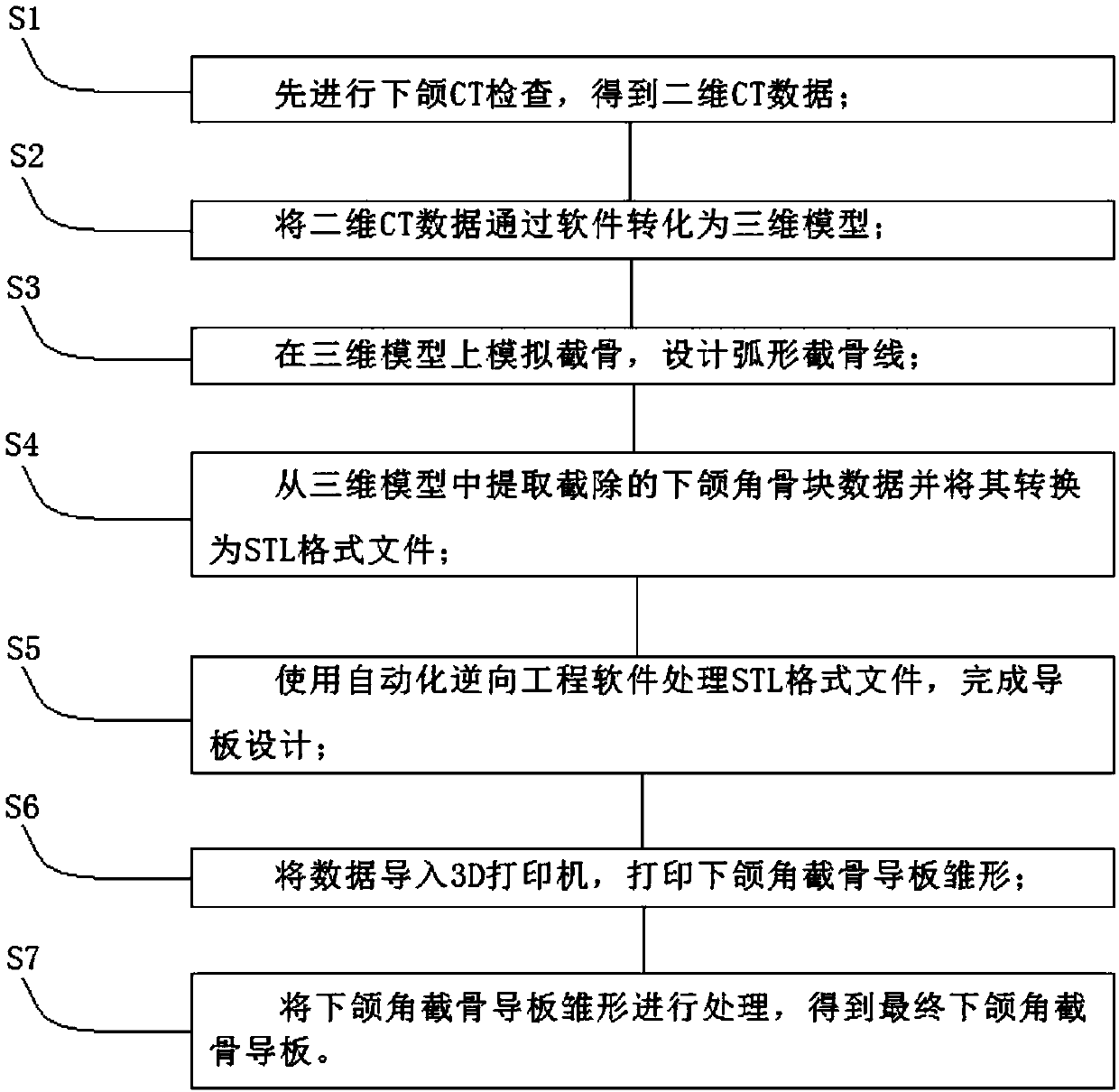

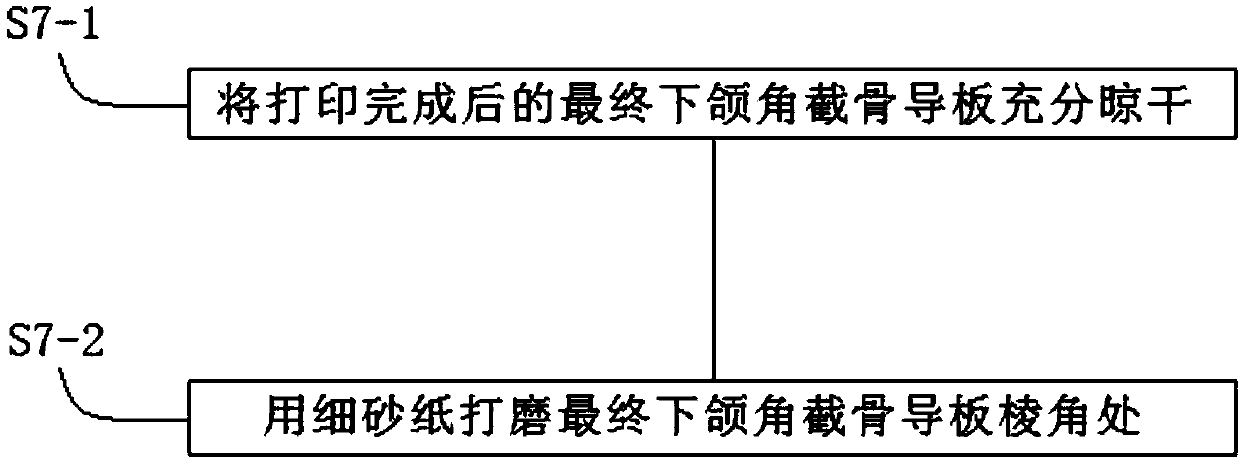

[0032] Such as Figure 1-Figure 3 As shown, the present invention provides a method for preparing a mandibular angle osteotomy guide plate based on 3D printing. First, mandibular CT examination is performed to obtain two-dimensional CT data; the two-dimensional CT data is converted into a three-dimensional model by software; Bone, design arc osteotomy line; extract the excised mandibular angle bone block data from the 3D model and convert it into STL format file; use automated reverse engineering software to process the STL format file to complete the guide plate design; import the data into the 3D printer , print the prototype of the mandibular angle osteotomy guide plate; process the prototype of the mandibular angle osteotomy guide plate to obtain the final mandibular angle osteotomy guide plate. In this way, after many times of clinical practice, the feasibility of placing the osteotomy guide plate in the operation area was firstly verified; secondly, the mandibular angle ...

Embodiment

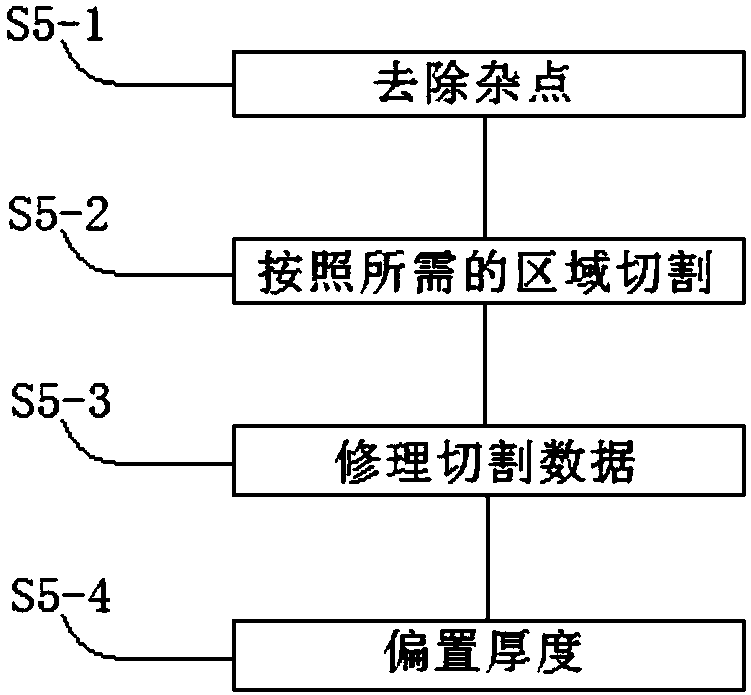

[0039] After the patient was admitted to the hospital, he underwent CT examination, imported the CT data into the ProPlan software, and converted the two-dimensional CT data into a three-dimensional model. With the participation of the patient, the osteotomy was simulated on the three-dimensional model, without damaging the inferior alveolar neurovascular bundle. Next, design an arc-shaped osteotomy line, and measure it with software to ensure that the two sides of the mandibular osteotomy are basically symmetrical, accurate to 0.01mm; extract the data of the resected mandibular angle bone block from the computer 3D model and convert it into an STL format file , import it into the GeoMagic software and open it, and then complete the design of the osteotomy guide plate through the following four steps: 1. Remove miscellaneous points; 2. Cut according to the required area; 3. Repair the cutting data; 4. Offset thickness, in short, first Hollow out the 3D model of the amputated ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com