Chute mounting structure for pouring concrete columns and method of use thereof

A concrete column and installation structure technology, which is applied in building construction, building material processing, construction, etc., can solve the problems of poor molding quality of concrete pouring columns, improve the quality of one-time molding, ensure the molding effect, and simplify the construction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

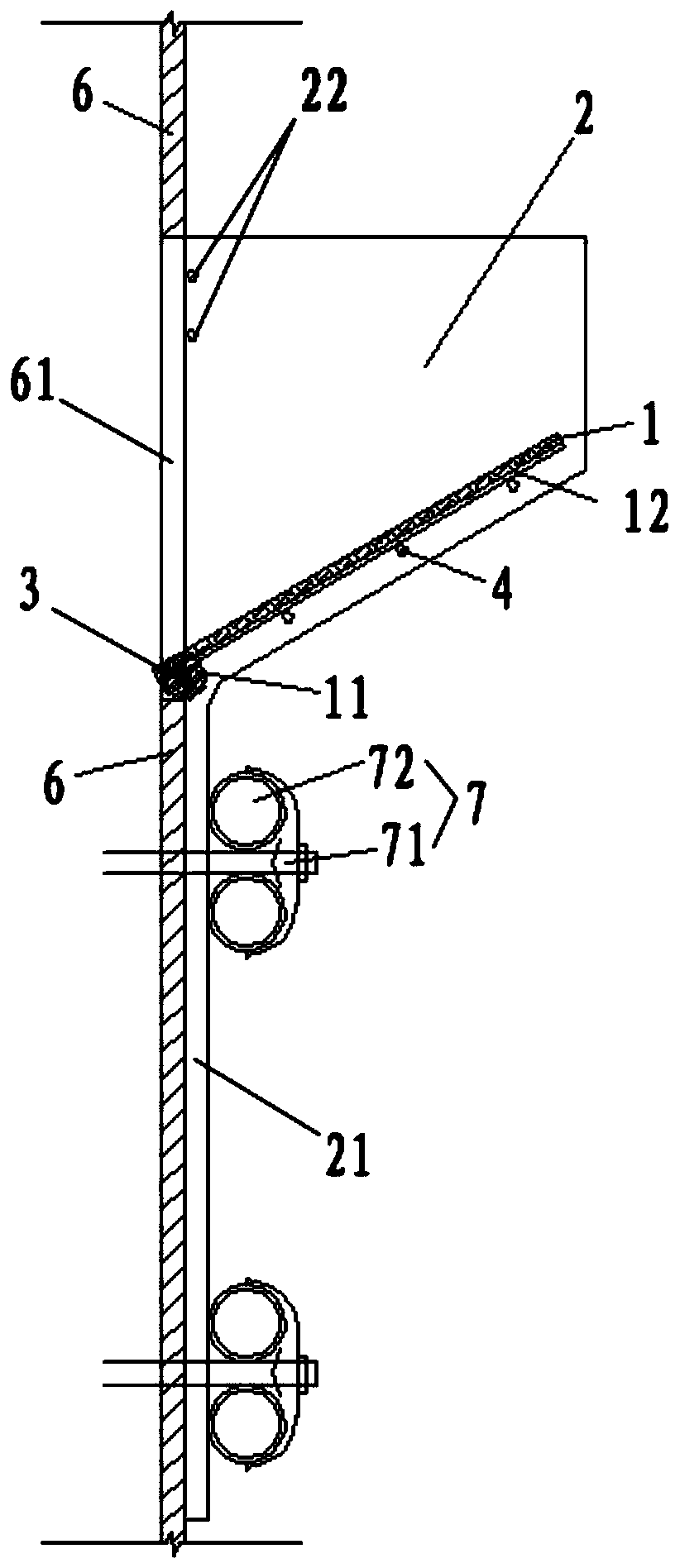

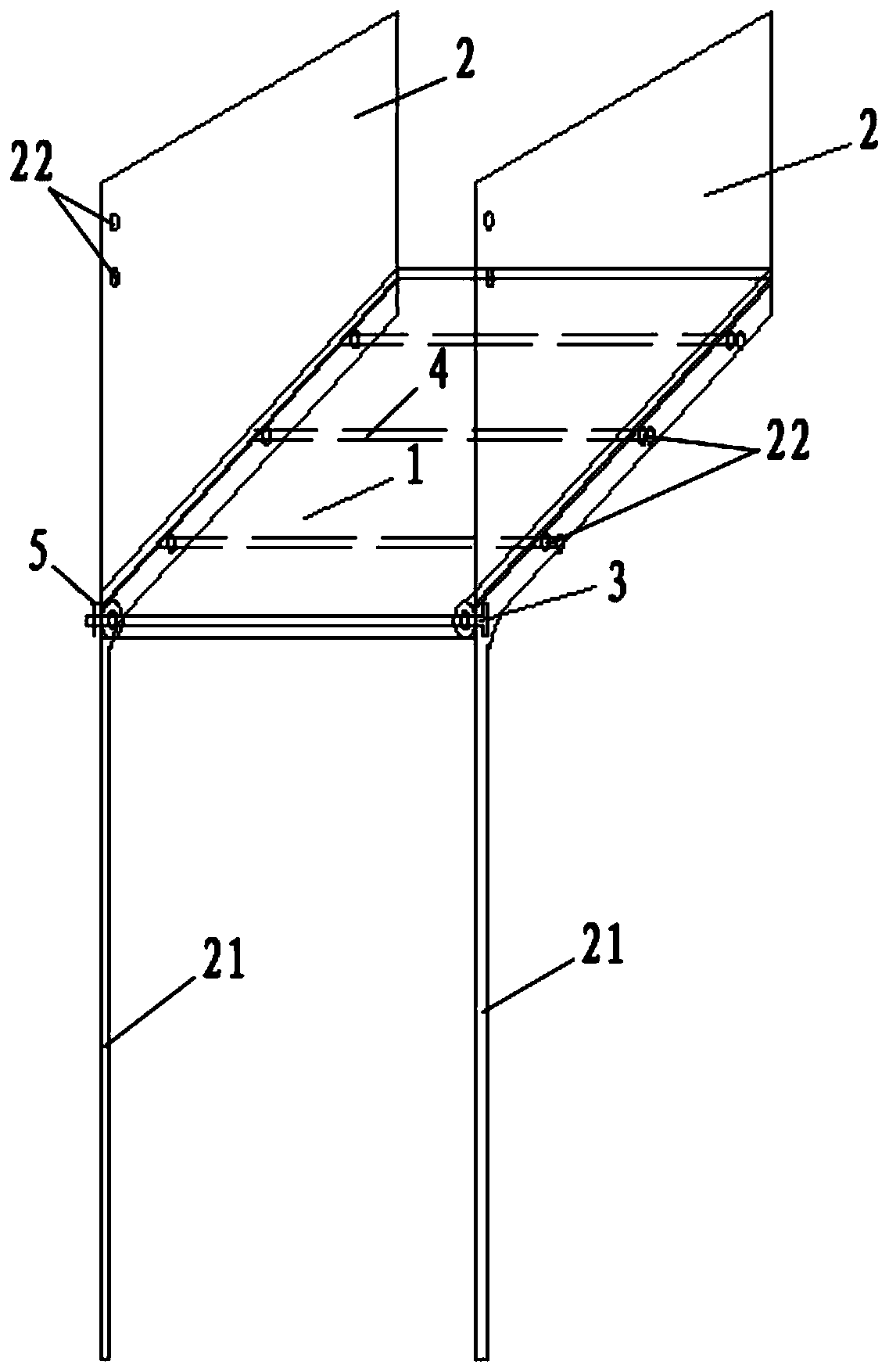

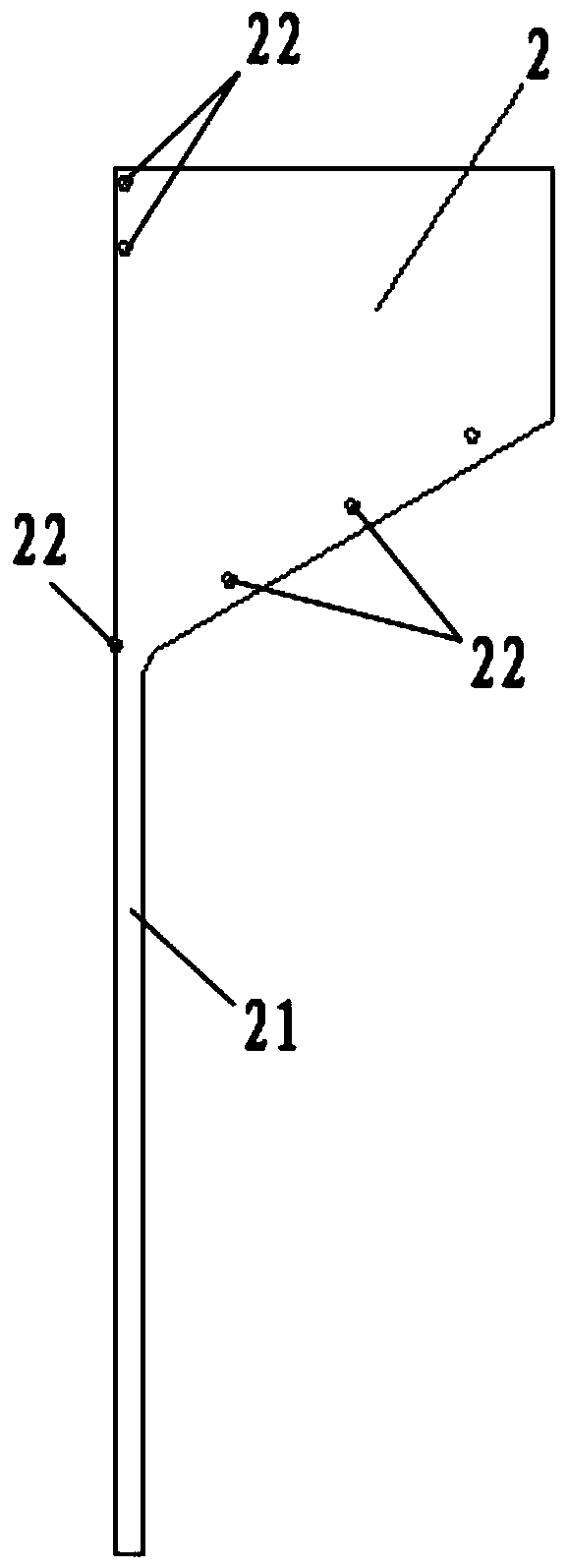

[0031] like Figure 1 to Figure 4 As shown in , the chute installation structure for pouring concrete columns according to the present invention includes a formwork 6 for surrounding precast concrete columns, and along the height direction of the precast concrete columns, at least the concrete columns The template 6 corresponding to one side is provided with a concrete pouring port 61, and a chute device is respectively provided at each concrete pouring port 61, and the chute device includes a bottom plate 1 and a support mechanism that can be used to support the bottom plate 1; The bottom edge of the bottom plate 1 is in contact with the bottom edge of the concrete pouring port 61, and the bottom plate 1 can be turned over along its bottom edge, and the bottom plate 1 can be switched between the blocking position and the support position after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com