Method for measuring axial clearance of double-row conical bearing

A technology of axial clearance and tapered bearings, applied in the direction of mechanical clearance measurement, measuring devices, mechanical measuring devices, etc., can solve the problem of high accuracy of no-load measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

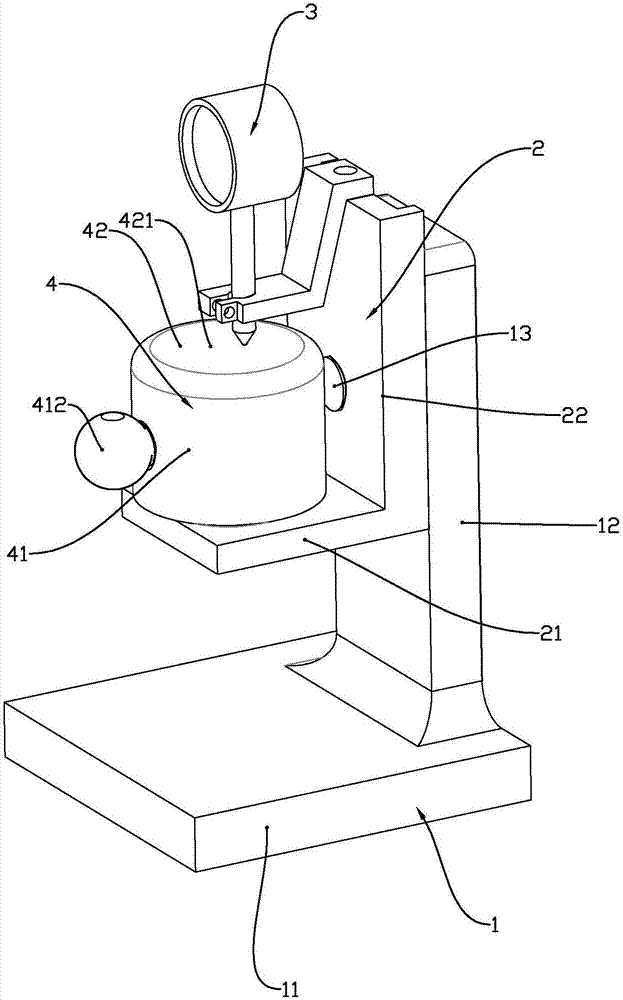

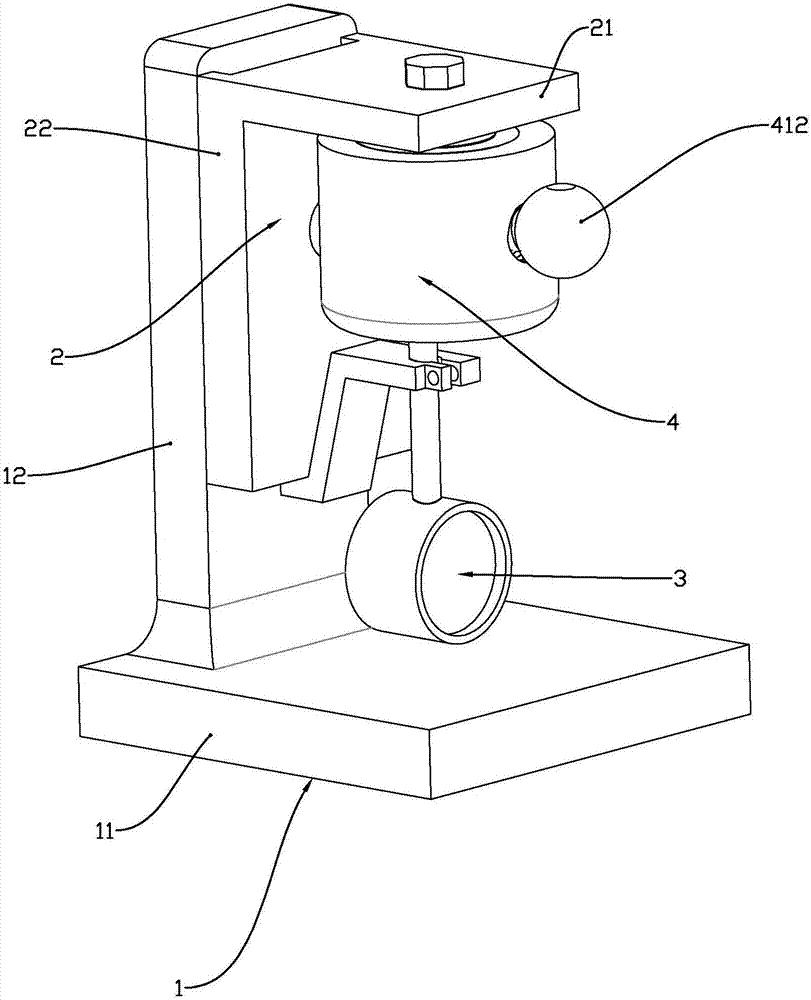

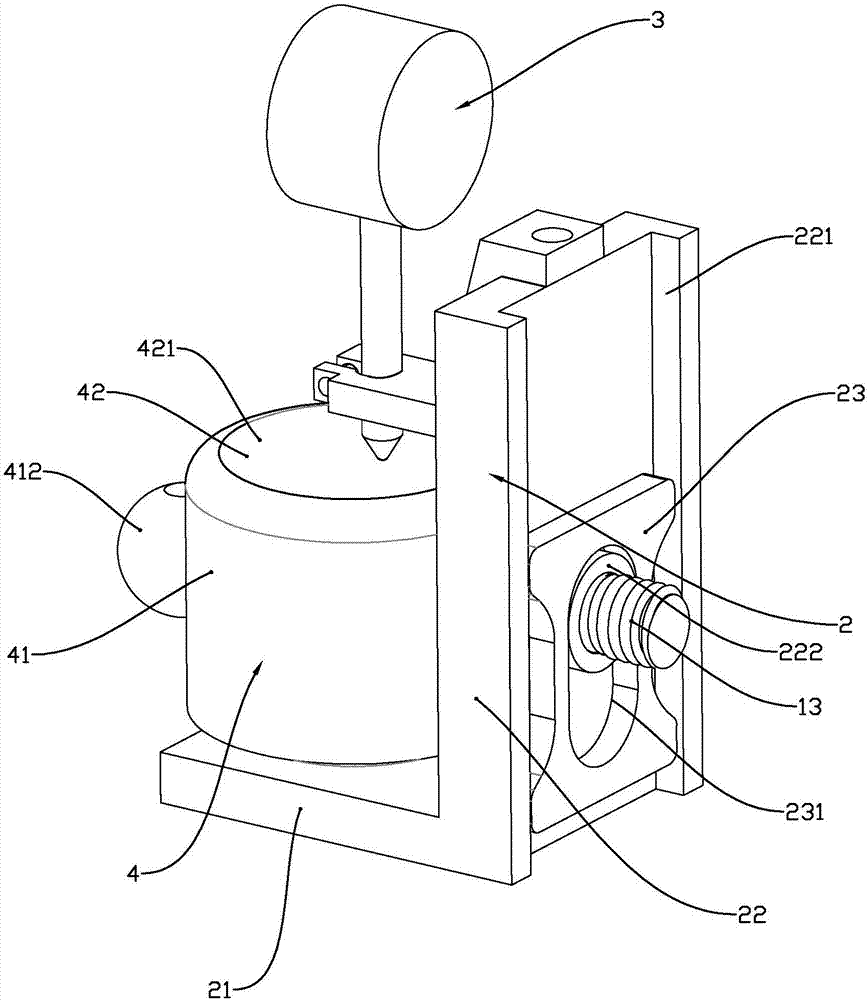

[0023] See attached Figure 1~5 , a method for measuring the axial clearance of a double-row tapered roller bearing disclosed in the present invention is carried out according to the following steps: Step 1, the inner ring of the double-row tapered roller bearing is fixed by clamping the two ends of the axial direction through the bearing fixing device, The outer ring of the double-row tapered roller bearing is suspended in the air so that the outer ring of the double-row roller bearing can be displaced axially relative to its inner ring. The double-row tapered roller bearing is placed vertically, and the head of the dial indicator is placed on the double-row On the horizontal plane of the axial end of the outer ring of the tapered roller bearing, the position of the dial indicator and the double-row tapered roller bearing are relatively fixed, and the outer ring of the double-row tapered roller bearing is moved so that the outer ring is opposite to the shaft of the inner ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com