Flyback converter with no need for the auxiliary winding

A flyback converter and auxiliary winding technology, applied in the field of flyback converters, can solve the problems of providing continuous and stable, relaxed output voltage regulation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

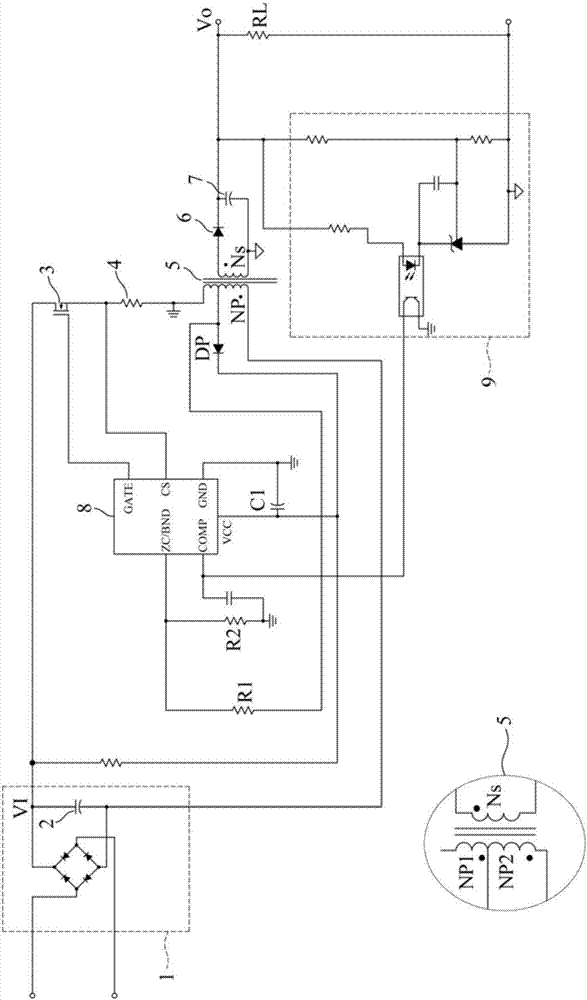

[0053] The following describes the embodiments of the present invention in more detail in conjunction with the drawings and component symbols, so that those skilled in the art can implement them after studying this specification.

[0054] due to Figure 4 In addition to the PWM controller with image 3 Many of the same features, among them image 3 Use a 6-pin PWM controller and Figure 4 Using 8-pin PWM controller, the following description will only image 3 A more detailed explanation is provided to clearly demonstrate the technical features of the present invention.

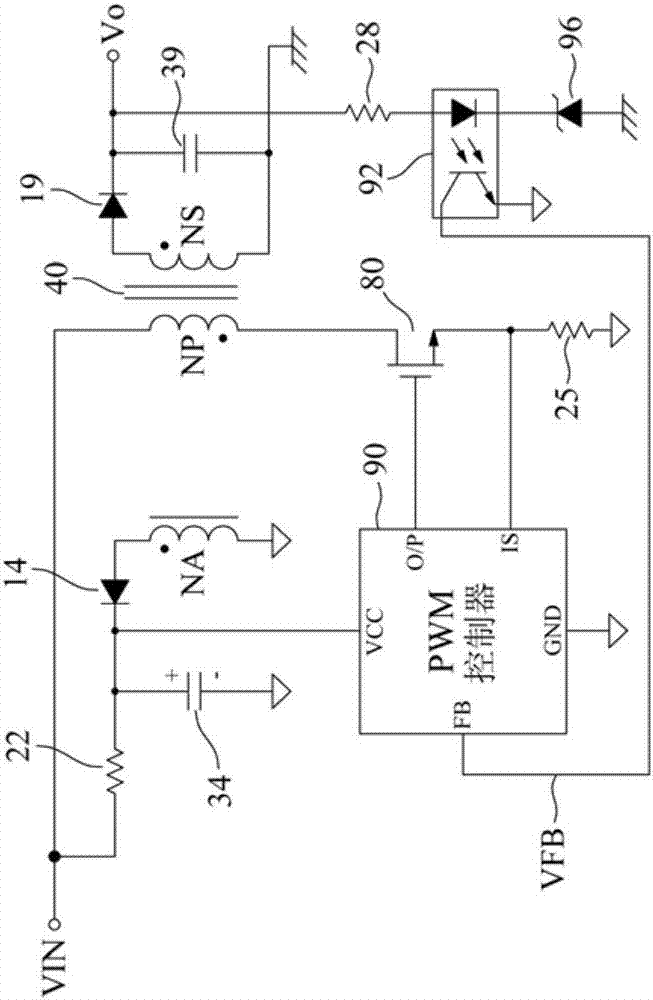

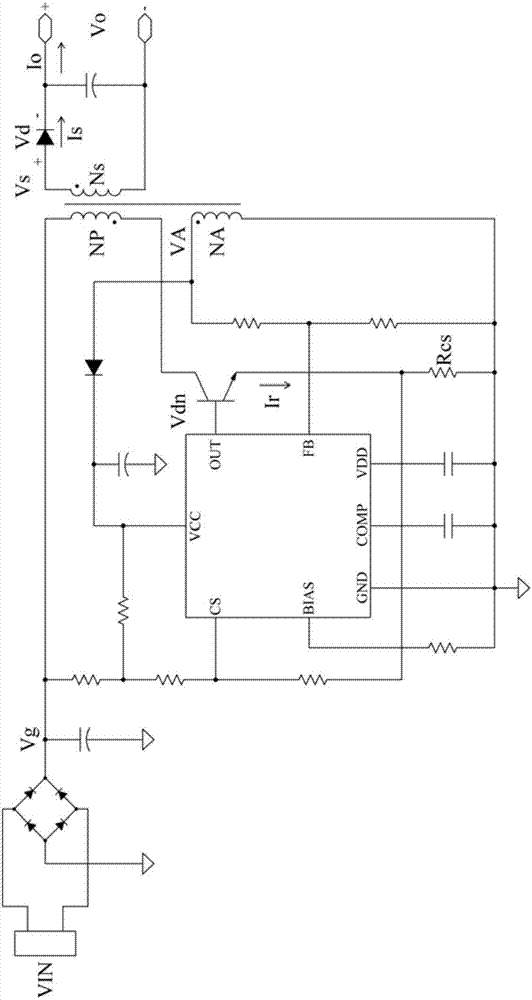

[0055] See image 3 , Which illustrates a flight structure built around a 6-pin PWM controller according to the present invention without auxiliary winding-high-side drive-secondary side regulation (Auxiliary-Free High-Side Driven Secondary-Side Regulated, AF-HSD-SSR) Back to the converter. The AF-HSD-SSR flyback converter of the present invention includes: AC-to-DC rectifier unit 1, input capacitor 2, switching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com