Coil part

A technology of coil components and recesses, applied in the direction of transformer/inductor parts, electrical components, transformer/inductor coils/windings/connections, etc., can solve the problem of large mode conversion characteristics and reduce the mode conversion characteristics. , the effect of reducing stray capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

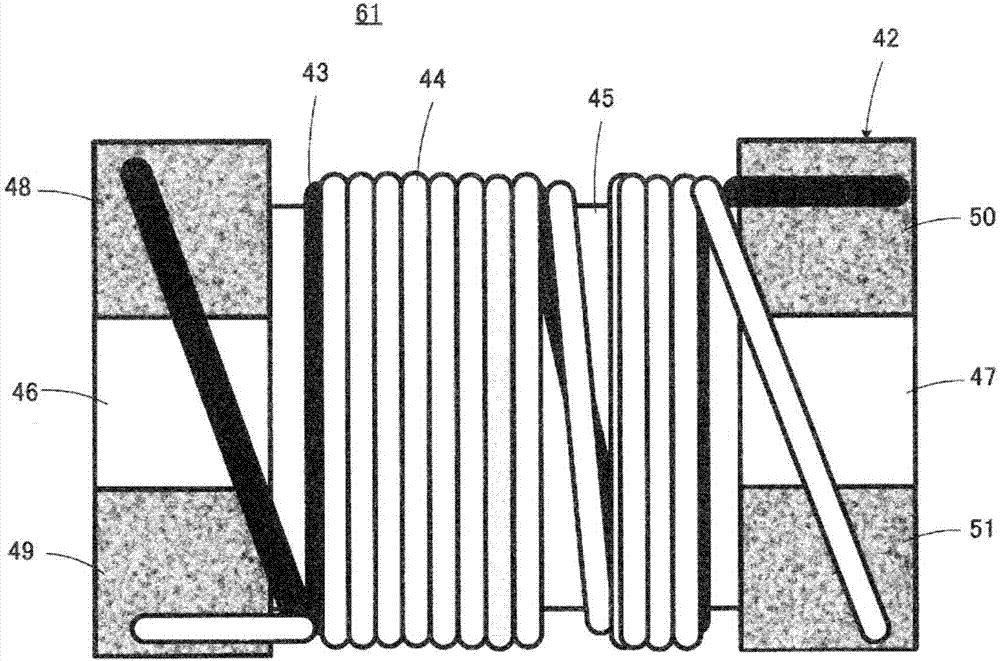

[0037] First, regarding the above-mentioned problem of increase in the mode conversion characteristic (hereinafter referred to as "Scd21"), the contents discovered by the inventors of the present application will be described below.

[0038] The cause of the above-mentioned problem is that the stray capacitance (distributed capacitance) generated in association with the common mode choke coil 41 breaks the balance of the signal passing through the common mode choke coil 41 .

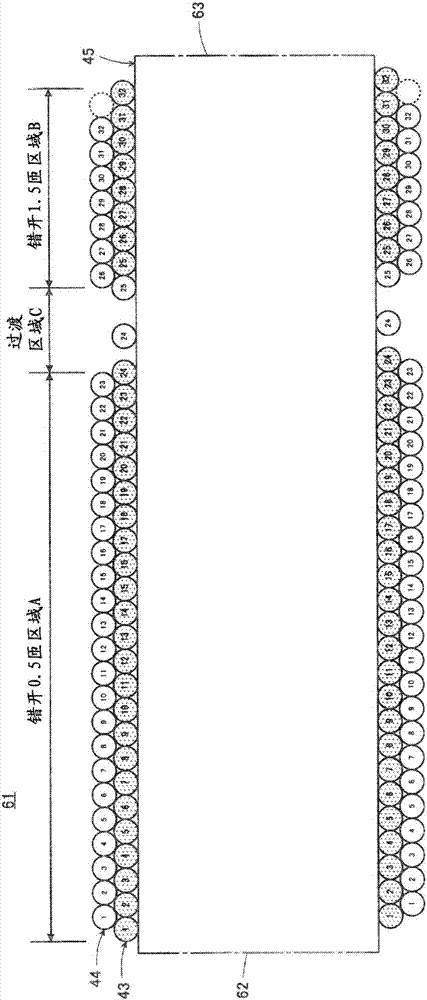

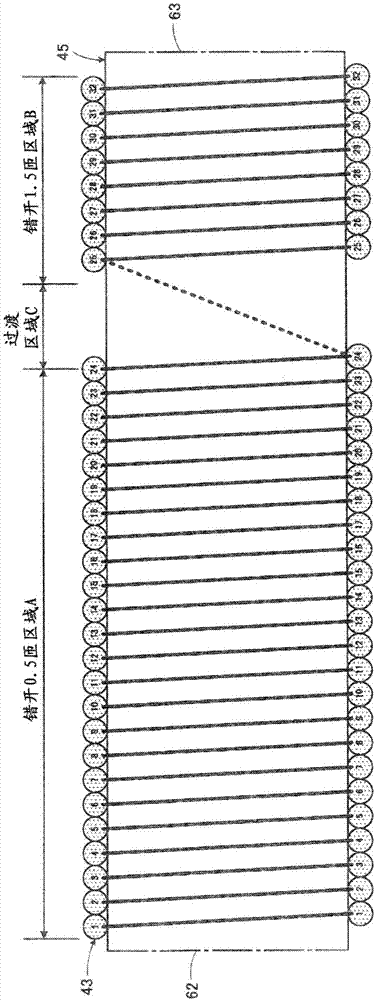

[0039] First, refer to Figure 11 as well as Figure 12 The stray capacitance generated in the common mode choke coil 41 will be described in more detail. exist Figure 11 In , a part of the winding state of the first wire 43 and the second wire 44 on the winding core portion 45 is enlargedly shown in a cross-sectional view. exist Figure 11 In , the numerals marked in the respective sections of the first line 43 and the second line 44 indicate the number of turns. That is, in Figure 11 In , the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com