Reaction vessel multi-shaft stirring device

A stirring device and reactor technology, which is applied in mixers with rotating stirring devices, chemical/physical/physical chemical fixed reactors, transportation and packaging, etc., can solve the problems of inconvenient use, difficult discharge of crystals, and uneven reaction And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

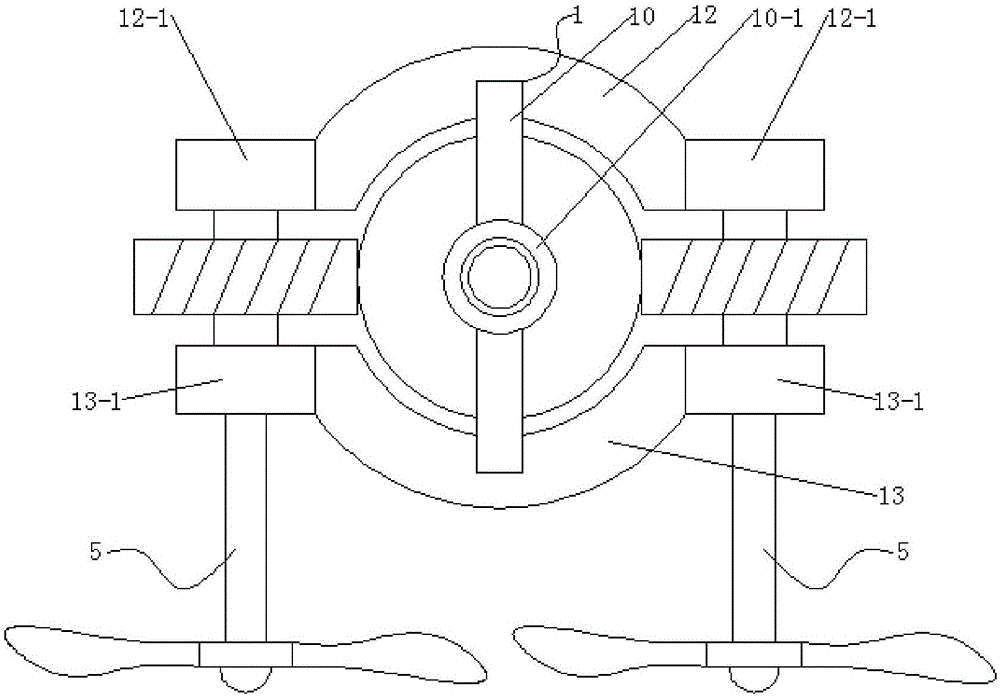

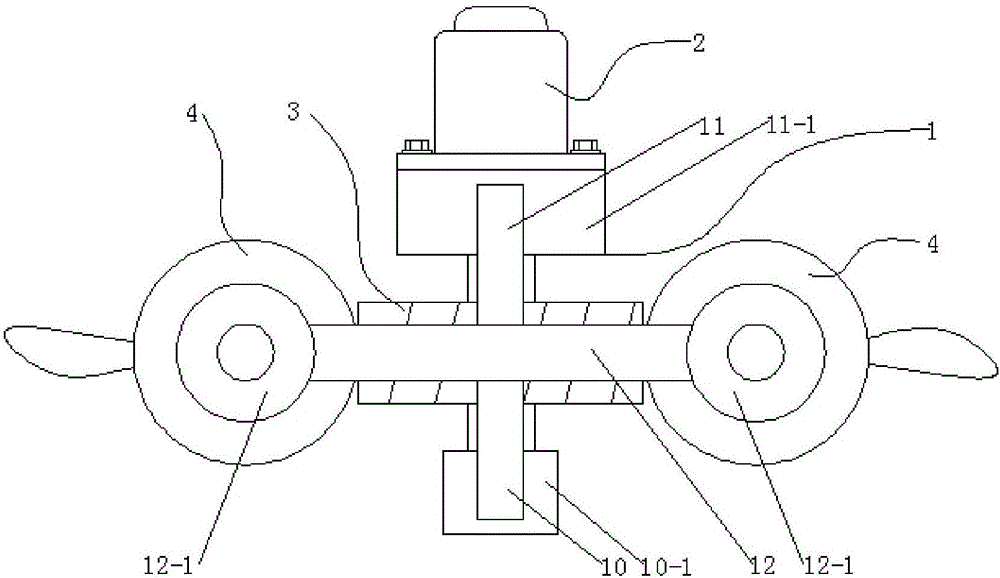

[0025] In this reaction kettle multi-axis stirring device, one end of the central shaft of the helical gear-3 is connected to the output shaft of the motor 2, and the other end is connected to the bearing seat-10-1 through a rolling bearing, so the motor 2 drives the helical gear-3 through the output shaft Rotate counterclockwise, because the first helical gear 3 meshes with the second helical gear 4, so the two helical gears 4 move relative to each other, and the two stirring shafts 5 also rotate relatively, and then the driven stirring blade 50 also moves relatively, so that The reaction liquid in the reaction kettle is mixed more evenly. In addition, the stirring blades 50 are double-rotating blades, and the stirring blades 50 driven by the double stirring shafts 5 rotate relatively, which improves the stirring effect.

[0026] The stirring seat 1 is cross-shaped, which ensures the stability of the meshing of the first helical gear 3 and the second helical gear 4 .

Embodiment 2

[0028] The upper end of the stirring shaft 5 is respectively connected with the bearing seat 3 12-1 and the bearing seat 4 13-1 through rolling bearings, and the stirring shaft 5 and the bearing seat 12-1 are installed and the stirring shaft 5 and the bearing seat are installed. The rolling bearing of four 13-1 adopts tapered roller bearings, and the axial stress strength of stirring shaft 5 is ensured by adopting bearing housing three 12-1 and bearing housing four 13-1 to fix the stirring shaft 5 and connecting with tapered roller bearings .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com