Assembly tool of escalator bridle

A technology for escalators and assembly tooling, which is applied in assembly machines, metal processing, manufacturing tools, etc., and can solve the problems of high work intensity and difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

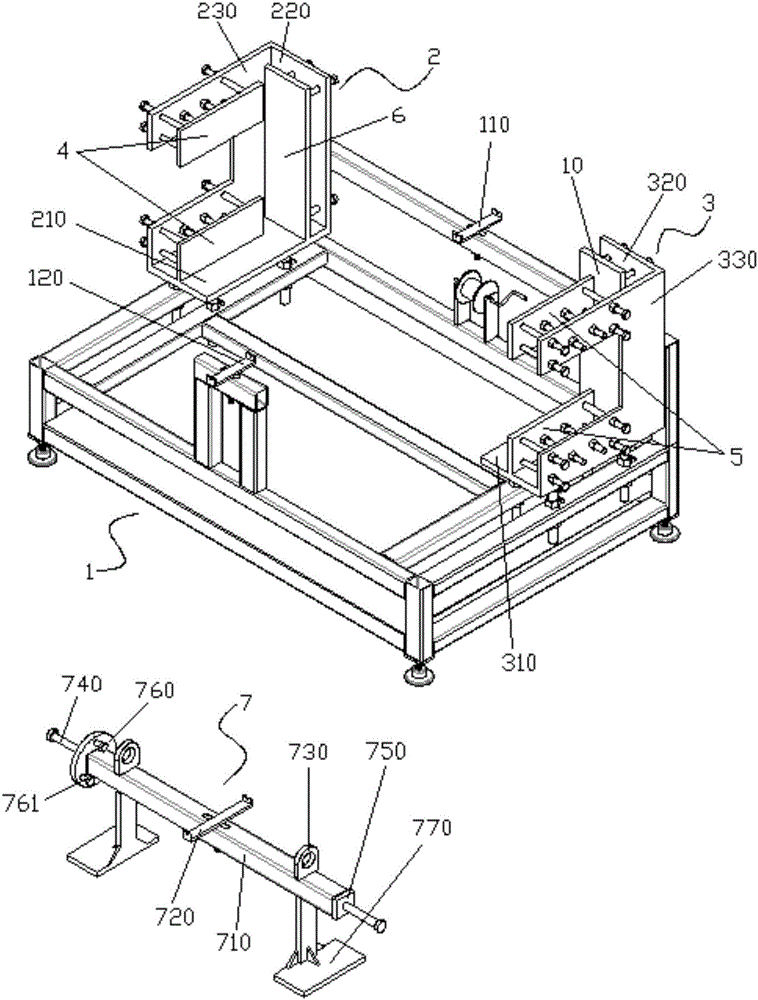

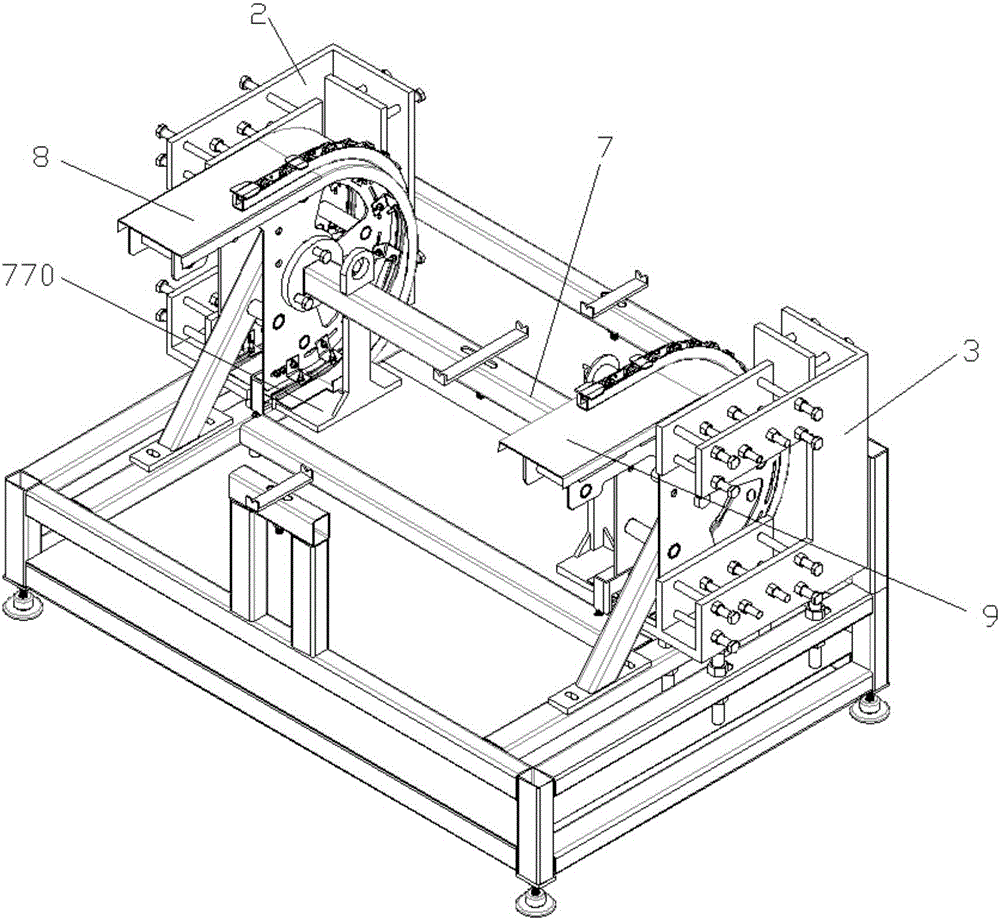

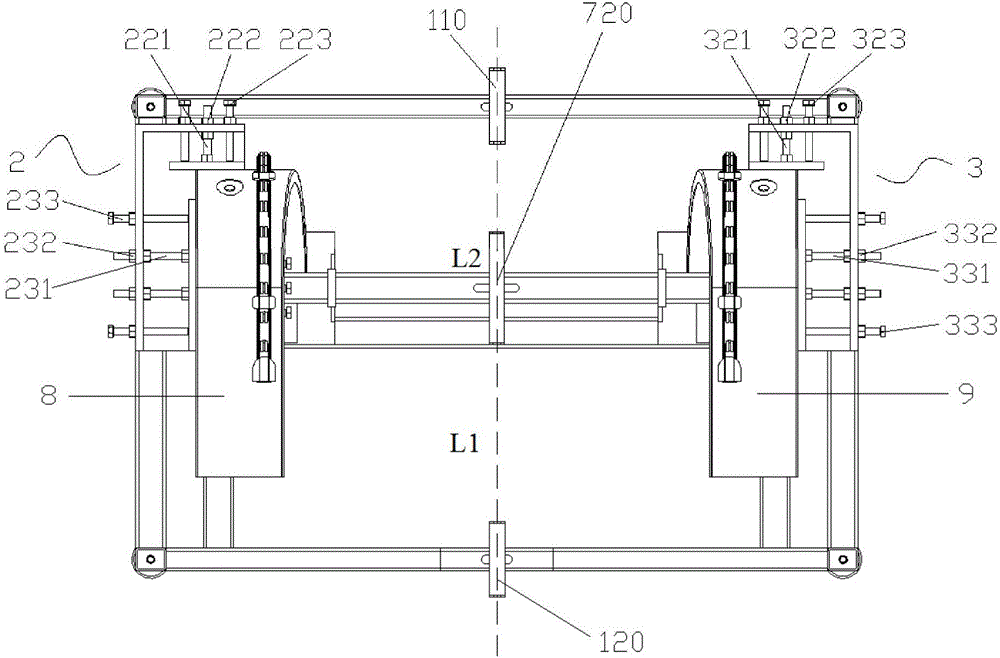

[0021] see figure 1 and figure 2, an assembly tool for an escalator halter, which includes a horizontal bracket 1; a left limiting plate 2, which is arranged on the left end of the horizontal bracket 1 and is fixedly connected with the horizontal bracket 1; the left limiting plate 2 includes: a horizontally arranged The left base plate 210, the left rear plate 220, which is arranged above the left base plate 210 and perpendicular to the left base plate 210, and the left side plate 230, which is arranged above the left base plate 210 and is perpendicular to the left base plate 210 and the left rear plate 220; Left working plate 4, it is arranged on the top of left bottom plate 210 and is parallel with left side plate 230, and left working plate 4 is movable and fixed relative to left side plate 230; Left rear working plate 6, it is arranged on the top of left bottom plate 210 and with The left rear plate 220 is parallel, and the left rear working plate 6 is movable and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com