A milling chatter test piece and its testing method

A technology of milling chatter and test method, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of process parameters such as milling chatter, and achieve the effect of simple and reliable test and simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

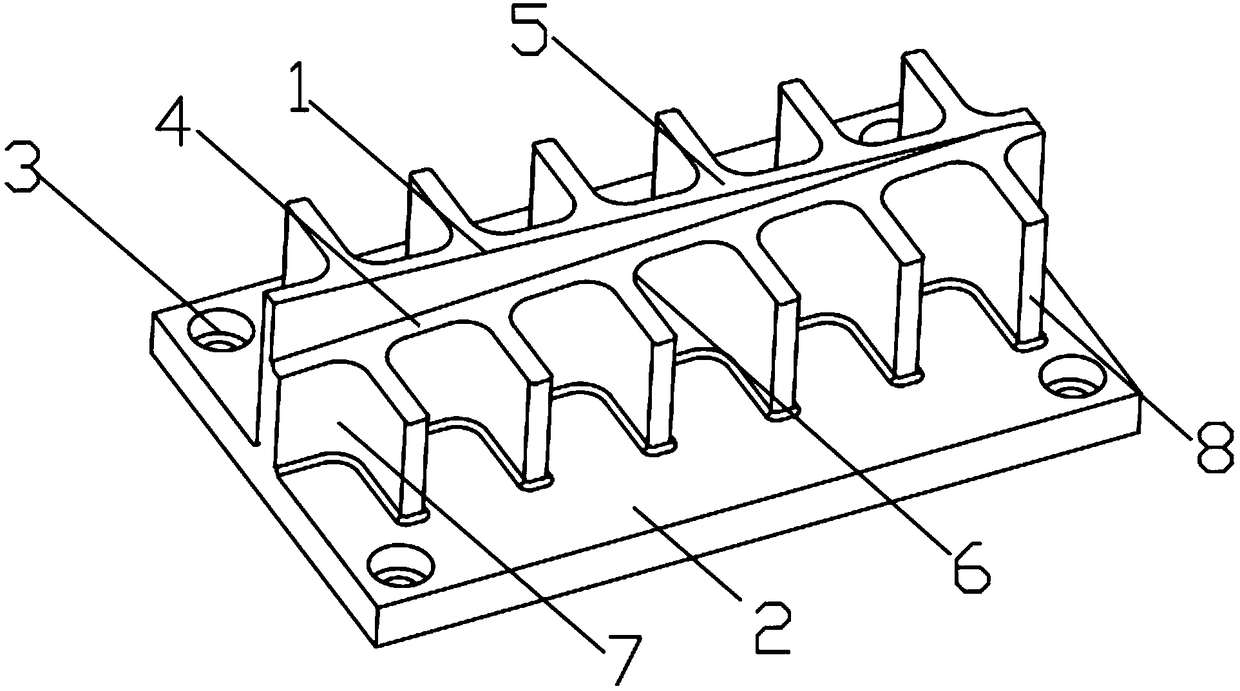

[0028] combined with figure 1 , attached figure 2 As shown, a milling chatter test piece, a milling chatter test piece, includes a base 2, and the base 2 is provided with a through hole 3 for fixing the base 2; the upper surface of the base 2 A milling test body 1 with two or more than two T-shaped test areas on the side is fixed, the upper surface of the milling test body 1 is provided with a slope and a reference plane 5, and a circle is provided at the bend of the T-shaped test area. Corner test area, where the intersection of the T-shaped test area and the bottom end of the slope is the milling area 7 .

[0029] Structural principles:

[0030] The test body 1 is placed on the base 2 of the milling chatter test piece, and the base 2 is fixed on the machine tool through the through hole 3. There are two or more T-shaped test areas on the side of the test body 1. The tool moves from T-shaped test area milling, the T-shaped test area can test the chatter of milling, the up...

Embodiment 2

[0032] In order to ensure the stability and continuity of the milling process, on the basis of the structure and principle of Embodiment 1, further combined with the attached figure 1 , attached figure 2 As shown, the T-shaped test area in this embodiment also includes a straight line test area and an over-rounded corner 8, the over-rounded corner 8 is arranged at the end of the straight line test area, and the reference plane 5 is perpendicular to the tool.

[0033] Structural principles:

[0034] Because the shape of the test area is T-shaped, in order to ensure the stability and continuity of the milling process, the end face of the T-shaped test area is provided with an excessive fillet 8, and the tool can directly mill the excessive circle on the T-shape after milling out of the straight line test area Angle 8, to maintain the continuity of milling. In order to obtain stable test parameters and facilitate the detection of milling chatter, datum plane 5 is perpendicular ...

Embodiment 3

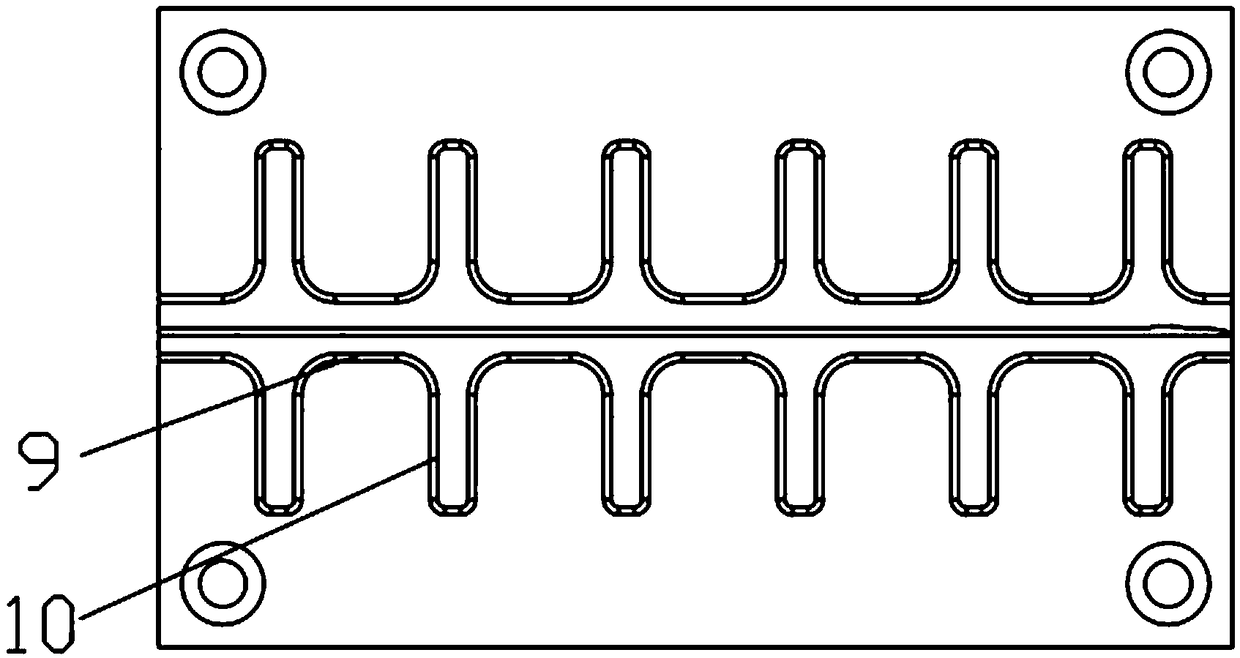

[0036] In order to better monitor the milling chatter of the tool in the fillet test area, on the basis of the structure and principle of Embodiment 1, further combined with the attached figure 1 , attached figure 2 As shown, the fillet test area in this embodiment includes a fillet milling area 9, a test fillet 6, and a fillet milling area 10, and the fillet milling area 9 and the fillet milling area 10 are respectively set On both sides of the test fillet 6.

[0037] Structural principles:

[0038] During the milling chatter test, the tool first passes through the fillet milling area 9, and after a certain distance of linear milling in the fillet milling area 9, the tool enters the fillet test area to ensure the stability of the chatter test at the fillet milling area , Fillet milling area 10 ensures that the tool mills out smoothly at the fillet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com