An electromechanical brake-by-wire

A brake-by-wire and electro-mechanical technology, applied in the direction of brake types, axial brakes, mechanical equipment, etc., can solve the problems of lack of automatic adjustment of brake clearance, large installation size, and complex brake structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

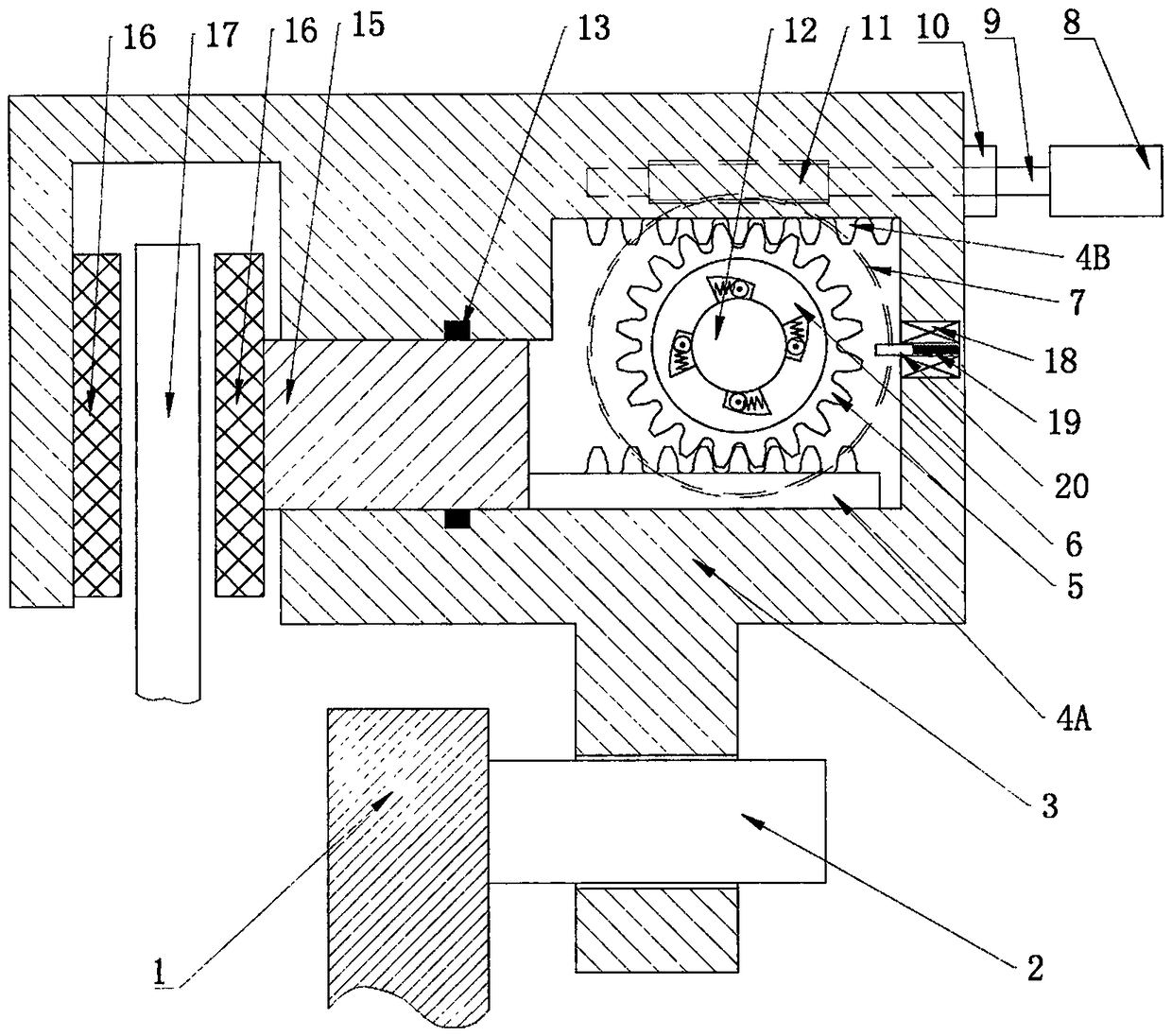

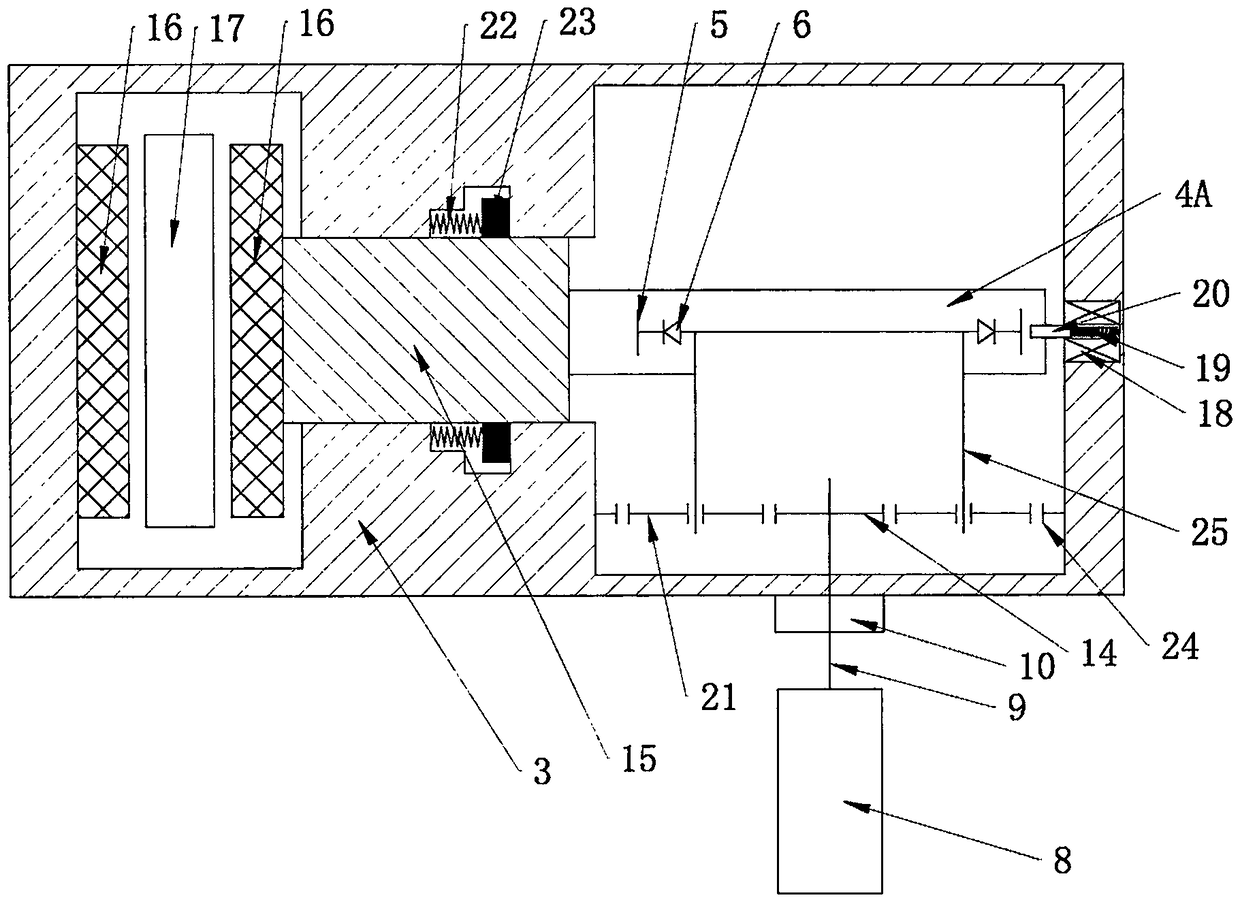

[0017] Reference attached figure 1 , an embodiment of the present invention will be described in detail.

[0018] Such as figure 1 As shown, an electromechanical brake by wire includes a brake caliper body (3) that can move on a guide pin (2), and the guide pin (2) is fixed on the brake caliper bracket (1). There is a brake disc (17) inside the jaw of the brake caliper body (3), and there are friction discs (16) on both sides of the brake disc (17), one is installed on the brake caliper body (3), and the other is installed on the piston (15), the piston (15) is installed on the brake caliper body (3) through the seal ring (13), and there is a relatively large friction force between the contact surface of the seal ring (13) and the piston (15), when the piston ( When the displacement of 15) is within the elastic deformation range of the sealing ring (13), there is no relative movement between the contact surfaces of the sealing ring (13) and the piston (15). One side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com