Secondary element for a filter system and filter system with a secondary element

A filter system and filter element technology, applied in membrane filters, dispersed particle filtration, gas treatment, etc., can solve problems such as long time intervals, and achieve the effect of stable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the drawings, the same or similar components are marked with the same reference numerals. The drawings show examples only and are not to be construed as limiting.

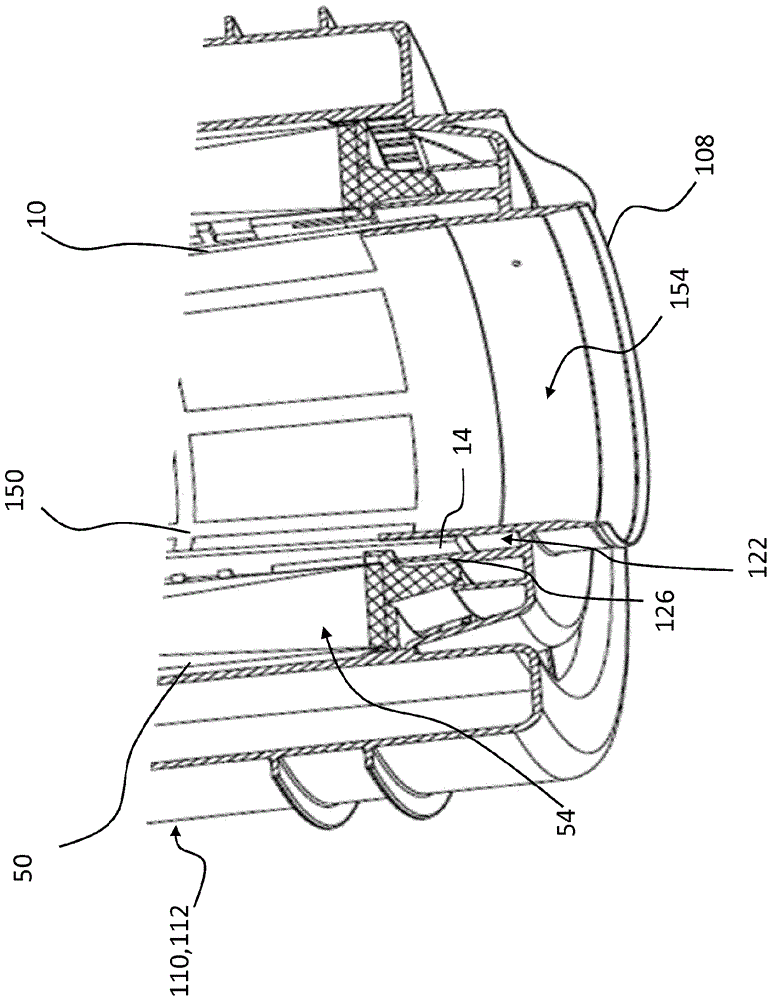

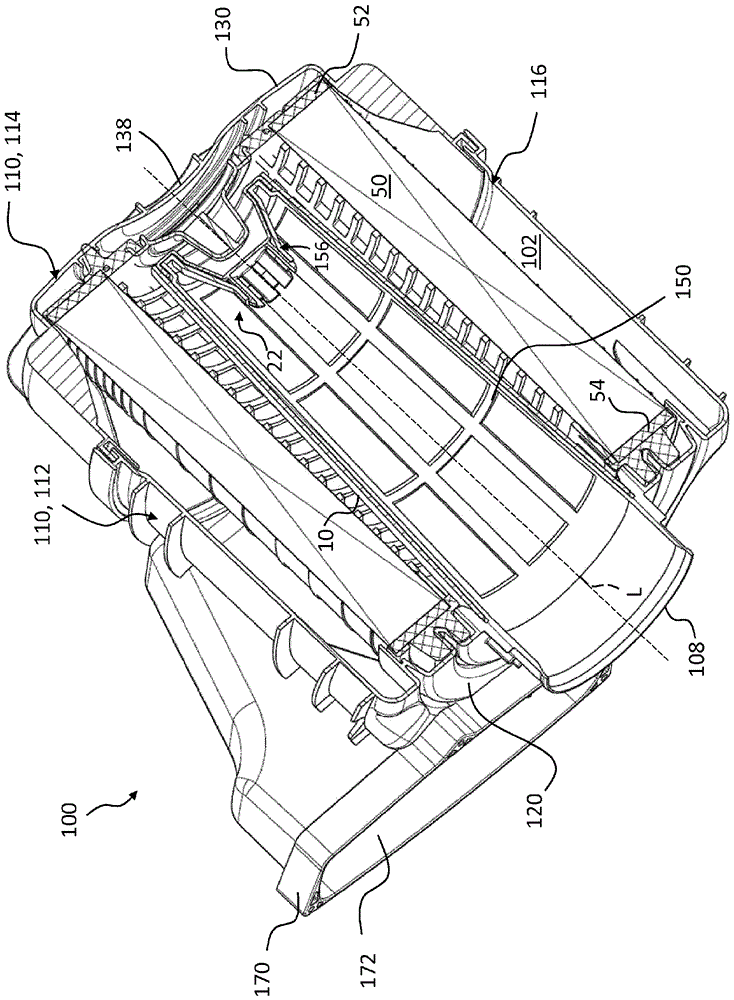

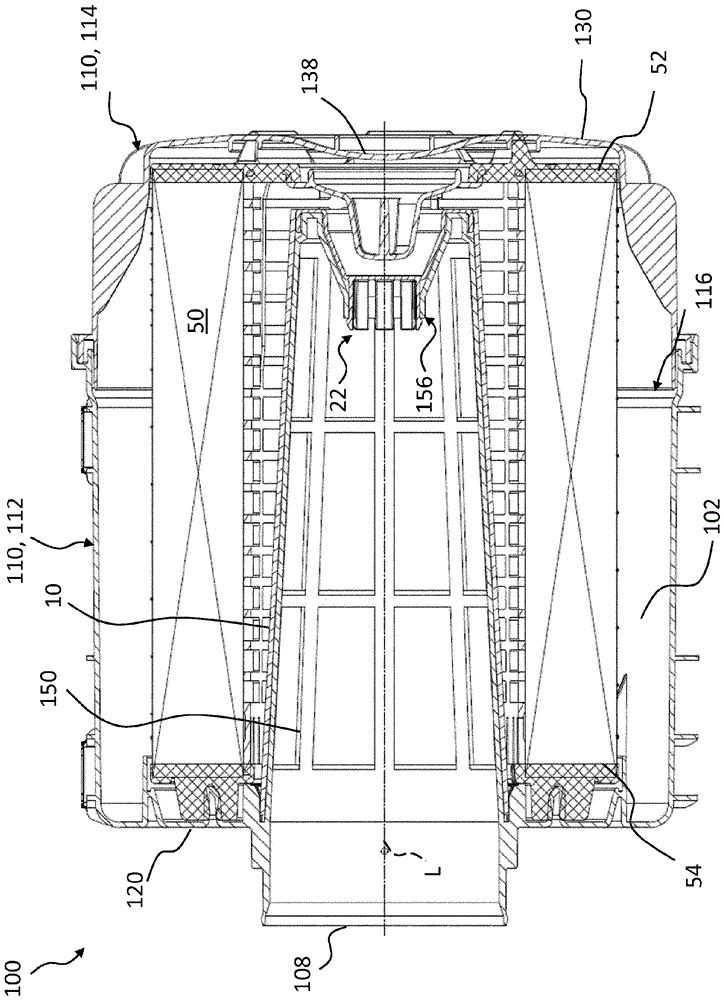

[0047] figure 1 A longitudinal section through a filter system 100 according to one exemplary embodiment of the invention is shown with a primary filter element 50 which surrounds a secondary element 10 on its clean side.

[0048] The filter system 100 comprises a housing 110 consisting of a tank 112 and a cover 114 which can be removed. figure 2 Details of the bottom area of the housing 110 are shown.

[0049] Housing 110 can be configured, for example, cylindrically. An inlet sleeve, not visible in the drawing, is arranged on housing 110 for supplying the fluid to be filtered, in particular air. The inlet sleeve can be arranged radially or tangentially on the housing 110 . The axial position is close to the bottom 120 of the housing 110 in a region in which an inflow protection 124 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com