Two-track vehicle

A technology for double-tracked vehicles, vehicles, applied in the direction of vehicle components, substructure, transportation and packaging, etc., to achieve the effect of improving rigidity, simple flat structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

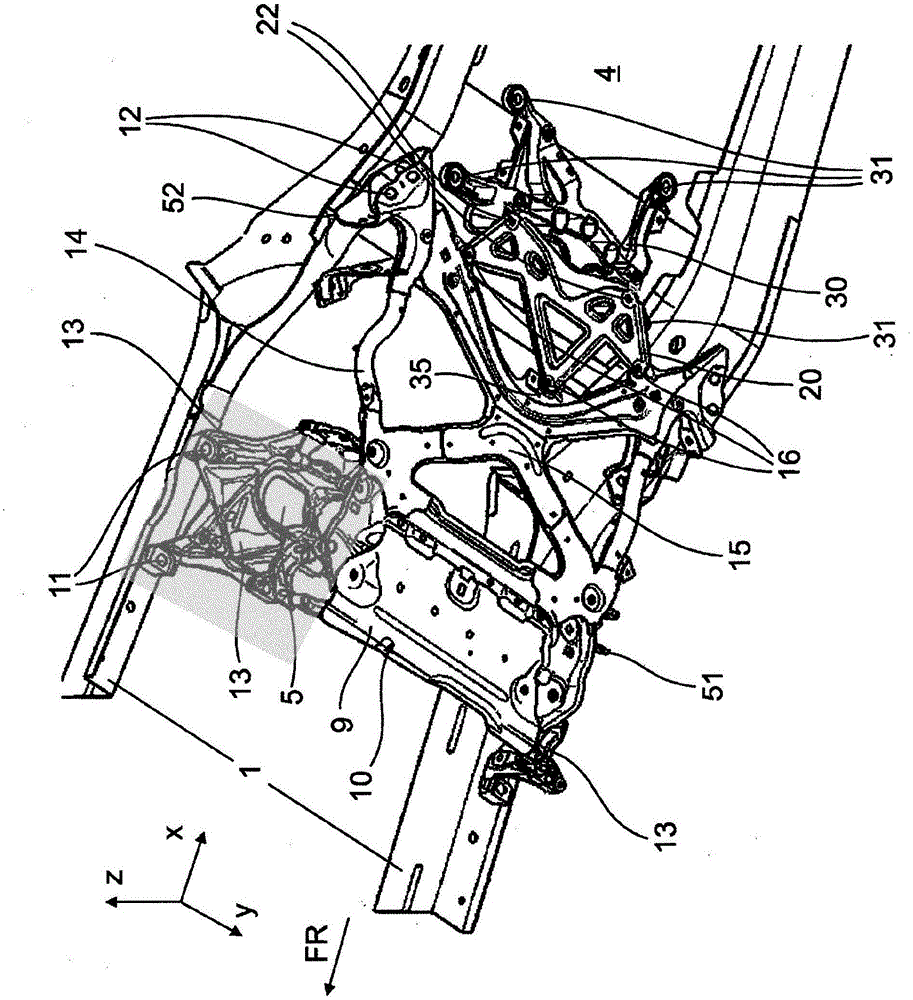

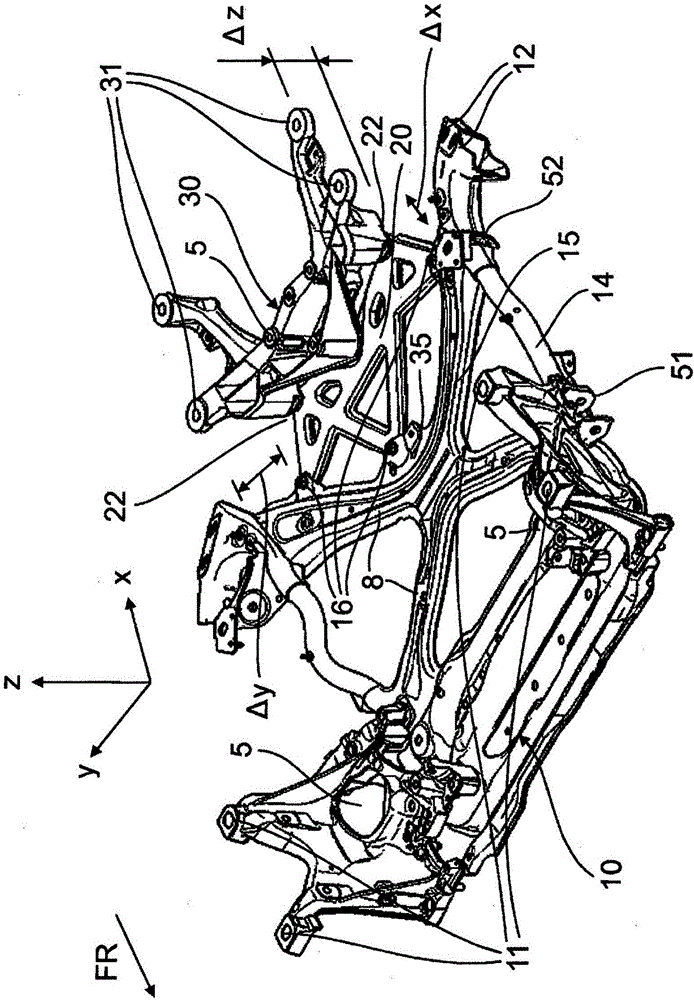

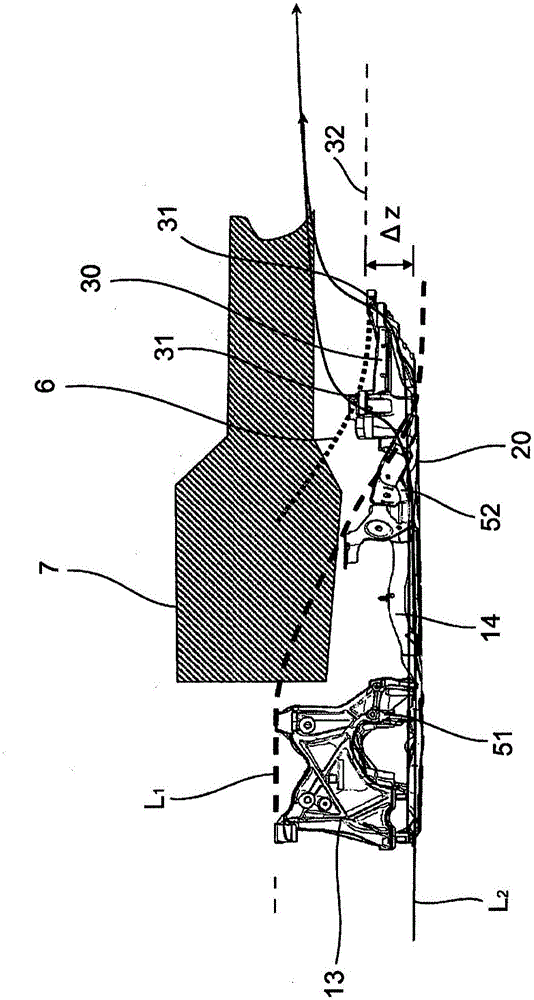

[0029] exist figure 1 The body structure of the front vehicle of the vehicle is shown in , and the scope shown is necessary for understanding the present invention. Accordingly, the body structure has two body side members 1 extending toward the rear in the vehicle longitudinal direction x, to which a subframe 10 is attached via a front fastening point 11 and a rear fastening point 12 ( via elastic supports not shown). The subframe 10 has two laterally opposite subframe longitudinal supports 14 in the vehicle longitudinal direction x, which are fastened at the front node elements 13 (eg cast nodes) by means of front fastenings. Point 11 is attached to the body rail 1 . The two front node elements 13 are connected to one another via the front subframe transverse carrier 9 .

[0030] The rear side member fastening point 12 of the subframe 10 is designed directly adjacent to the rear control arm bracket 52 on which the transverse control arm 53 is articulated in the assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com