Rice straw recycling machine

A technology of rice straw and recycling machine, which is applied in the field of agricultural machinery, can solve the problems of wasting user's time and achieve the effects of easy recycling, convenient use and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

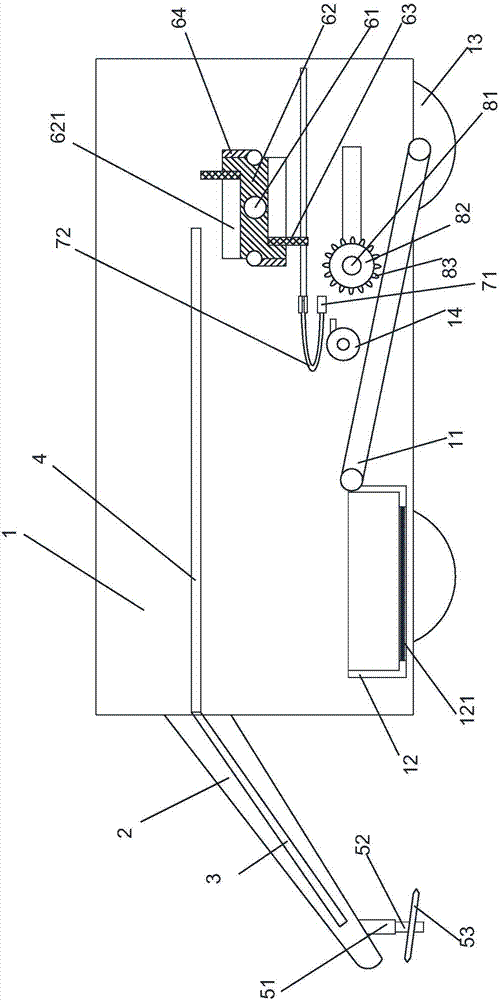

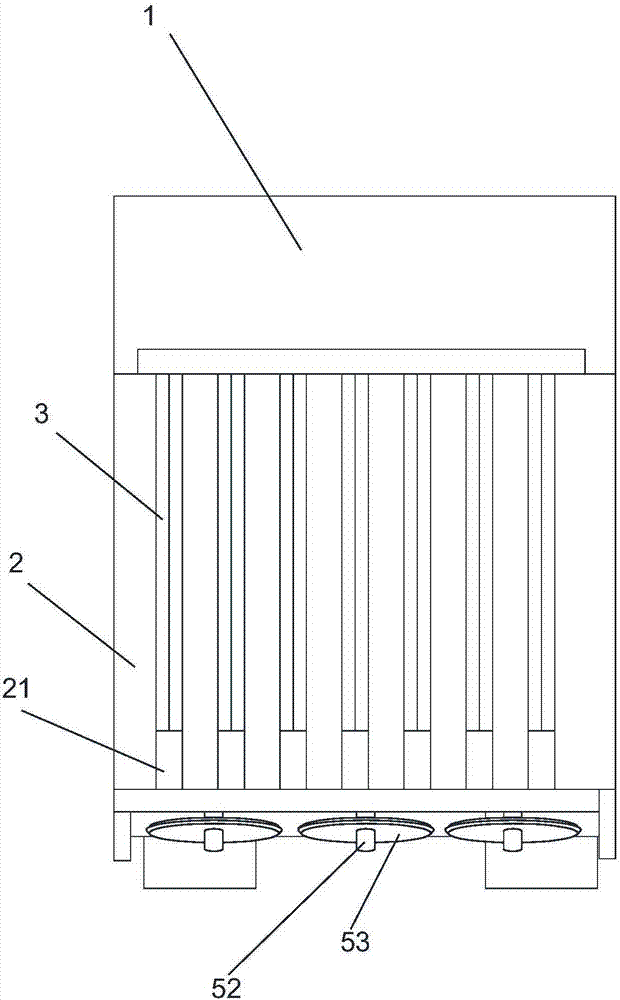

[0019] refer to figure 1 and figure 2 As shown, a rice straw recovery machine proposed by the present invention includes a car body 1, a mounting frame 2, a plurality of first conveyor belt groups 3, a plurality of second conveyor belt groups 4, a cutting mechanism, a gathering mechanism and a bundling mechanism ;

[0020] The mounting frame 2 is installed on the vehicle body 1, and the mounting frame 2 is provided with a plurality of material guide grooves 21. The first conveyor belt group 3 corresponds to the material guide grooves 21 one by one, and the first conveyor belt group 3 includes two first conveyor belts. belt, the two first conveyor belts are obliquely installed at the guide groove 21 on the mounting frame 2, and the height of the first conveyor belt gradually increases along the direction close to the car body 1;

[0021] The second transmission belt group 4 corresponds to the first transmission belt group 3 one-to-one, the second transmission belt group 4 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com