High-temperature forged piece cooling device with power generation function

A heat-dissipating device and high-temperature technology, applied in forging/pressing/hammer devices, manufacturing tools, heating/cooling equipment, etc., can solve the problems of heat waste, increase in ambient temperature, and deterioration of workers' working environment, and reduce the surrounding environment. The effect of temperature, heat dissipation and cooling is fast, and the effect of waste heat utilization is good.

Inactive Publication Date: 2017-12-08

HUBEI UNIV OF ARTS & SCI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, there are many high-temperature forgings in forging factories that need heat dissipation and cooling during the forging process. During the long-term natural cooling process, not only a large amount of heat is wasted in vain, but also the temperature of the surrounding environment rises, which affects the working environment of workers. deterioration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

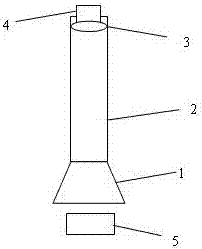

[0008] figure 1 As shown: a heat collecting cover 1 is arranged above the high temperature forging 5, a hot air flow chimney 2 is installed on the heat collecting cover 1, and a generator 4 with an impeller 3 is fixed on the upper end of the hot air flow chimney 2, forming a power generation function High temperature forging cooling device.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention provides a heat dissipation device for high temperature forgings with power generation function. The technical scheme adopted is: a heat collecting cover is arranged above the high temperature forging, a hot air chimney is installed on the heat collecting cover, and a generator with an impeller is fixed on the upper end of the hot air chimney to form a high temperature forging with power generation function. cooling device. Through the above arrangement, the heat dissipated by the high temperature forging can be collected by the heat collecting cover, forming a rapid upward hot air flow in the hot air chimney, so that the high temperature forging can quickly dissipate heat, and at the same time, the hot air drives the impeller to rotate and drive the generator to generate electricity. It solves the problems of slow heat dissipation, long heat dissipation time, waste heat waste and increase in ambient temperature of high-temperature forgings after forging. Very good application prospects.

Description

technical field [0001] The invention relates to a heat dissipation device, in particular to a high temperature forging heat dissipation device with power generation function. Background technique [0002] At present, there are many high-temperature forgings in forging factories that need heat dissipation and cooling during the forging process. During the long-term natural cooling process, not only a large amount of heat is wasted in vain, but also the temperature of the surrounding environment rises, which affects the working environment of workers. deterioration. Contents of the invention [0003] The purpose of the present invention is to provide a high-temperature forging cooling device with power generation function, which has the characteristics of fast heat dissipation and cooling of forgings, simple structure, good waste heat utilization effect, and can significantly reduce the ambient temperature. [0004] The invention includes a heat collecting cover, a hot air ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): B21K29/00

CPCB21K29/00

Inventor 李文联李杨李凯李圣

Owner HUBEI UNIV OF ARTS & SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap