A kind of high-strength and high-toughness magnesium alloy plate and preparation method thereof

A high-strength, high-toughness, magnesium alloy technology, applied in the field of high-strength, high-toughness magnesium alloy sheet and its preparation, can solve the problems of incompatibility between high strength and high toughness, balance restricting wide application, unfavorable material forming and processing, etc., to achieve improved Competitiveness, improvement of structure and performance stability, and improvement of plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

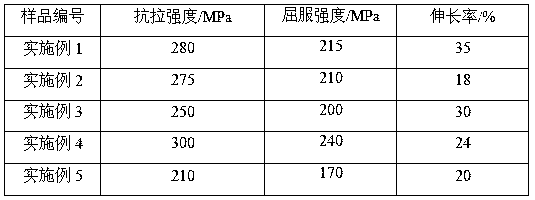

Embodiment 1

[0026] A high-strength and high-toughness magnesium alloy plate is made of the following components in weight percentage: Li: 10.5%, Al: 2%, Ag: 0.5%, Sn: 0.8%, Ca: 0.5%, Sr: 0.5%, The balance is Mg.

[0027] The preparation method of the above-mentioned high-strength and high-toughness magnesium alloy plate comprises the following steps:

[0028] (1) Mixing is carried out according to the mass percentage of each component in the alloy, and the raw materials are melted under an argon atmosphere at 750°C to obtain molten metal;

[0029] (2) Casting the molten metal obtained in step (1) to obtain an ingot; then keeping the ingot at 350°C under an argon atmosphere for 10 hours to obtain a homogenized ingot;

[0030] (3) Remove the surface scale (peeling and polishing) from the homogenized ingot obtained in step (2), and then roll it once to obtain a slab;

[0031] (4) Heat the slab obtained in step (3) at 385°C for 8 minutes, then quench it, and then age it at 70°C for 4 hours;...

Embodiment 2

[0034] A high-strength and high-toughness magnesium alloy plate is made of the following components by weight percentage: Li: 8%, Al: 5%, Ag: 1.5%, Sn: 0.8%, Ca: 2%, Sr: 1.2%, The balance is Mg.

[0035] The preparation method of the above-mentioned high-strength and high-toughness magnesium alloy plate comprises the following steps:

[0036] (1) Mixing is carried out according to the mass percentage of each component in the alloy, and the raw materials are melted under an argon atmosphere at 680°C to obtain molten metal;

[0037](2) Casting the molten metal obtained in step (1) to obtain an ingot; then keeping the ingot at 340°C under an argon atmosphere for 12 hours to obtain a homogenized ingot;

[0038] (3) Remove the surface scale (peeling and polishing) from the homogenized ingot obtained in step (2), and then roll it once to obtain a slab;

[0039] (4) Heat the slab obtained in step (3) at 360°C for 10 minutes, quench it, and then age it at 60°C for 5 hours; roll it t...

Embodiment 3

[0042] A high-strength and high-toughness magnesium alloy plate is made of the following components in weight percentage: Li: 11%, Al: 2%, Ag: 1.2%, Sn: 1.0%, Ca: 1.2%, Sr: 0.75%, The balance is Mg.

[0043] The preparation method of the above-mentioned high-strength and high-toughness magnesium alloy plate comprises the following steps:

[0044] (1) Mixing is carried out according to the mass percentage of each component in the alloy, and the raw materials are melted under an argon atmosphere at 800°C to obtain molten metal;

[0045] (2) Cast the molten metal obtained in step (1) to obtain an ingot; then keep the ingot at 360°C for 8 hours under an argon atmosphere to obtain a homogenized ingot;

[0046] (3) After removing the surface oxide skin (peeling and polishing) from the homogenized ingot obtained in step (2), the slab is obtained by extrusion;

[0047] (4) Heat the slab obtained in step (3) at 410°C for 5 minutes, then quench it, and then age it at 80°C for 3 hours;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com