Contaminant removing device of washing machine

A washing machine, connecting rod technology, applied in washing devices, other washing machines, textiles and paper making, etc., to achieve the effect of large scale removal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

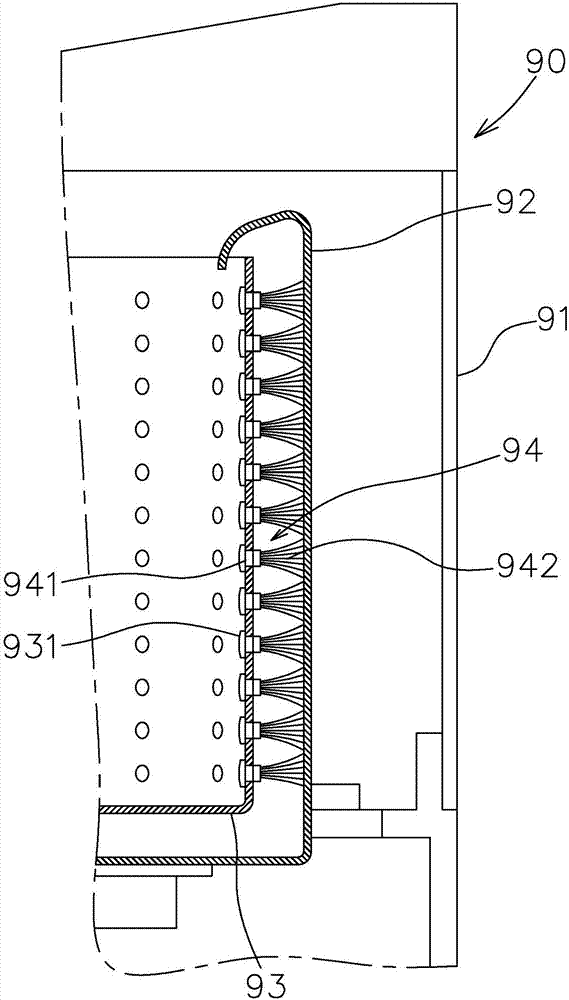

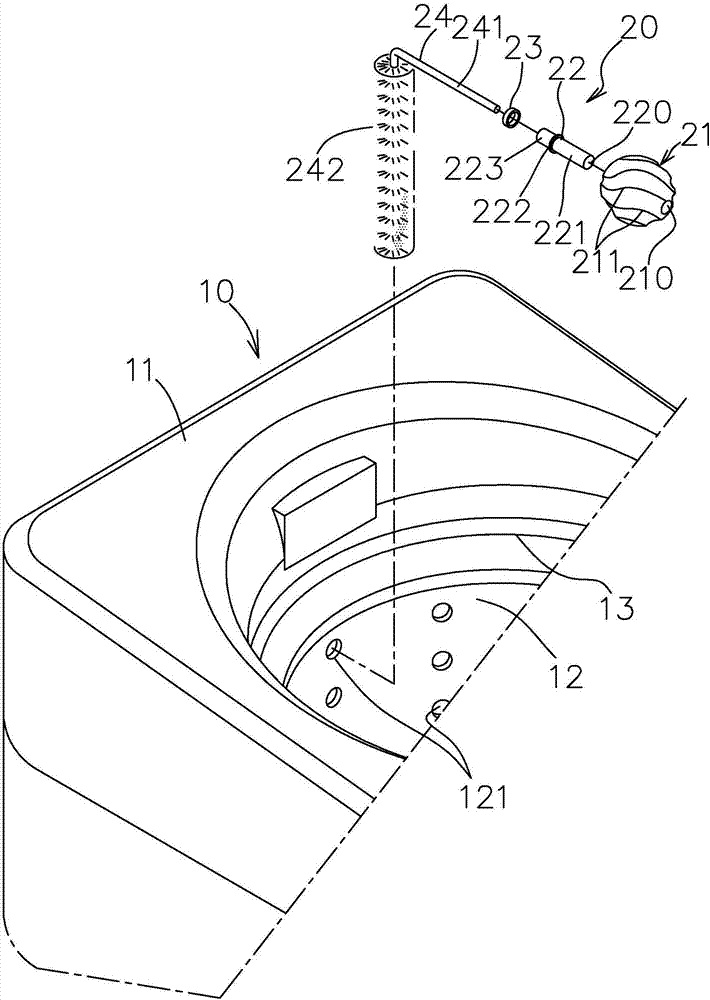

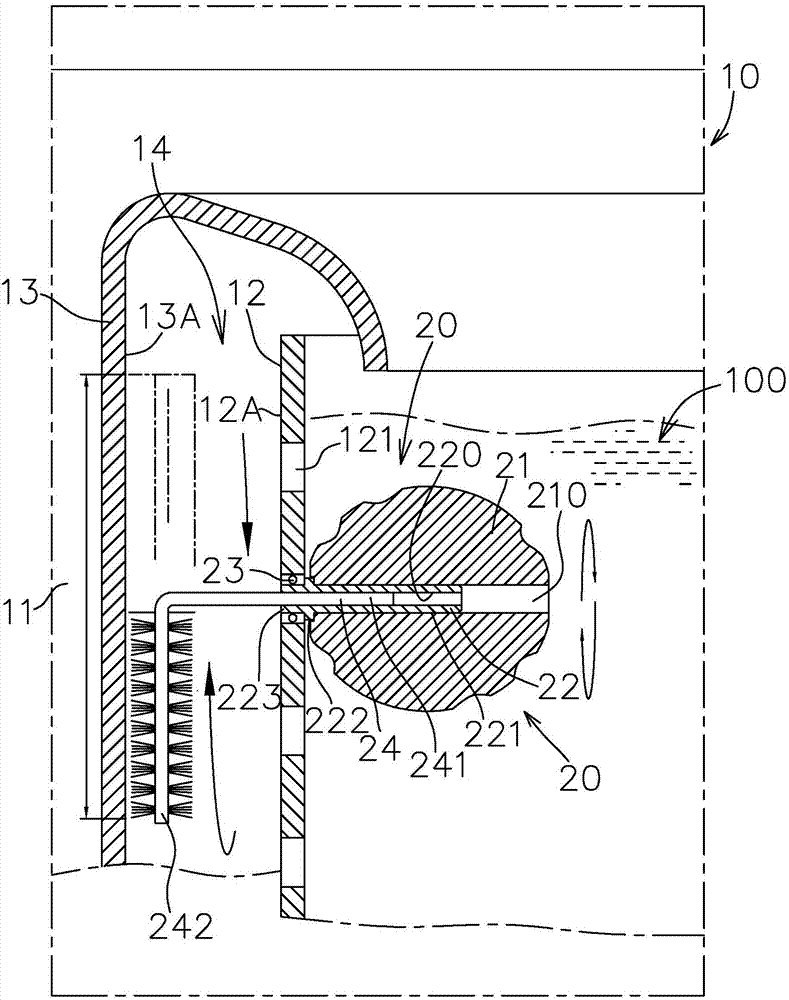

[0055] see Figure 2 to Figure 4, is the first embodiment of the washing machine descaling device of the present invention, these drawings are simplified schematic diagrams, which only schematically illustrate the basic structure of the present invention, and the composition drawing shown is not limited to the same as the actual implementation Shape and size ratio. As shown in the figure, the washing machine descaling device of the present invention includes a descaling device 20, which is used in a washing machine 10; A laundry inner tank 12 (inner cylinder) is arranged in the outer tank 13, and there is a gap space 14 between the laundry outer tank 13 and the laundry inner tank 12. The laundry inner tank 12 is controlled by a transmission mechanism (not shown) of the body 11. ) is linked and rotated for laundry operation. A plurality of perforations 121 are provided on the peripheral wall of the laundry inner tank 12 , and the perforations 121 communicate with the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com