High-corrosion-resistance compound sealing vacuum valve and manufacturing technique of sealing system comprising same

A composite sealing and manufacturing technology, applied in shaft seals, valve details, valve devices, etc., can solve the problems of weak anti-corrosion ability of liquid valves, unsatisfactory sealing effect, rubber corrosion, etc., and achieve strict controllability of the shaping process. , good sealing, strong anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

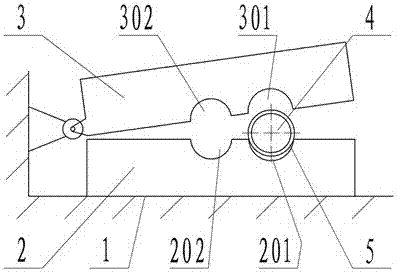

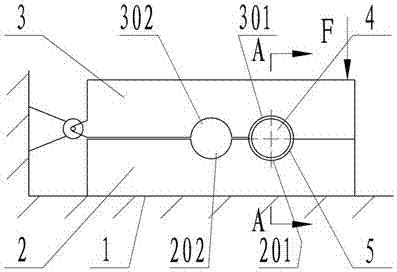

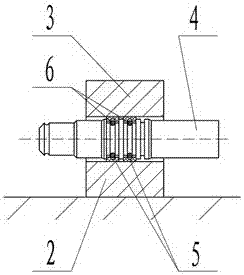

[0024] Below in conjunction with accompanying drawing, the specific implementation of this design will be further described: Figure 7 Or as shown in 8, the inner core of the nut 8 is provided with outer teeth, and the outer side of the nut 8 is provided with inner teeth, the valve core 4 is screwed on the inner core of the nut 8 through counterclockwise screw teeth, and the upper end of the valve seat 7 is screwed with clockwise screw teeth. Fit on the nut 8 outer inner teeth, so that the valve core 4 can be moved up and down by rotating the nut 8, so that the valve core matching cone surface 401 and the valve seat matching cone surface 702 are separated and attached, that is, the opening and closing of the vacuum valve is realized. One of the inlet and outlet pipe ports on the valve seat 7 is arranged at the bottom of the valve seat 7, and the opening is opposite to the valve core 4, and the other nozzle is arranged on the side wall of the valve body 701; two rubber O-rings 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com