Flange assembly

A technology of flanges and components, which is applied in the direction of flange connections, passing components, pipes/pipe joints/fittings, etc., can solve the problems of difficult precise control of relative positions, inability to play a sealing role, and affect normal work, etc., to improve installation Efficiency and accuracy, avoiding offset, and ensuring production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

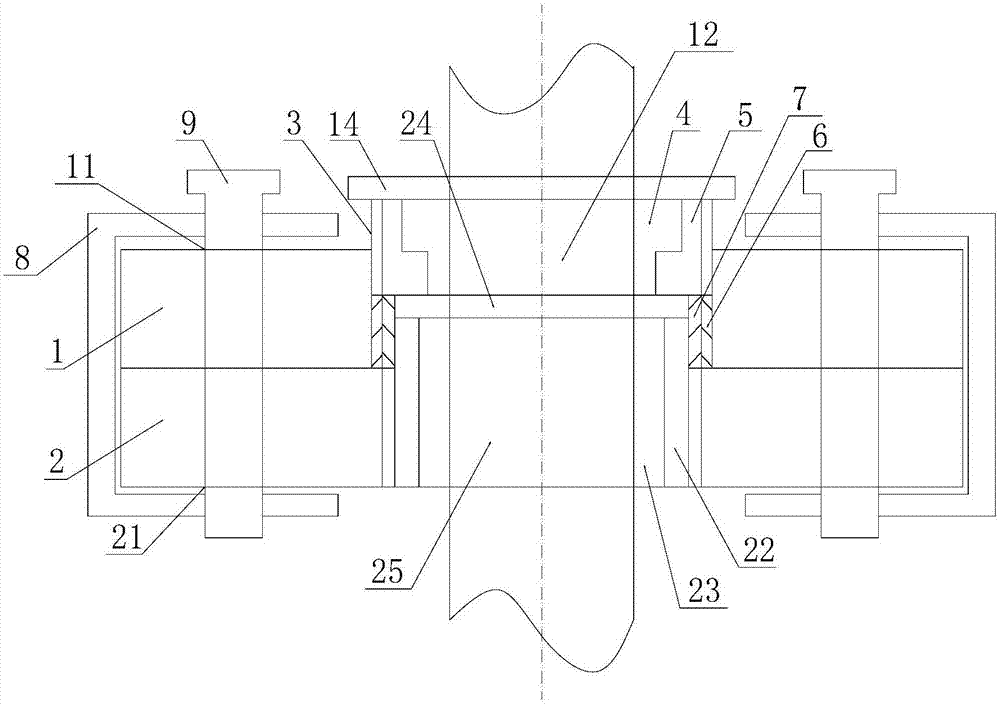

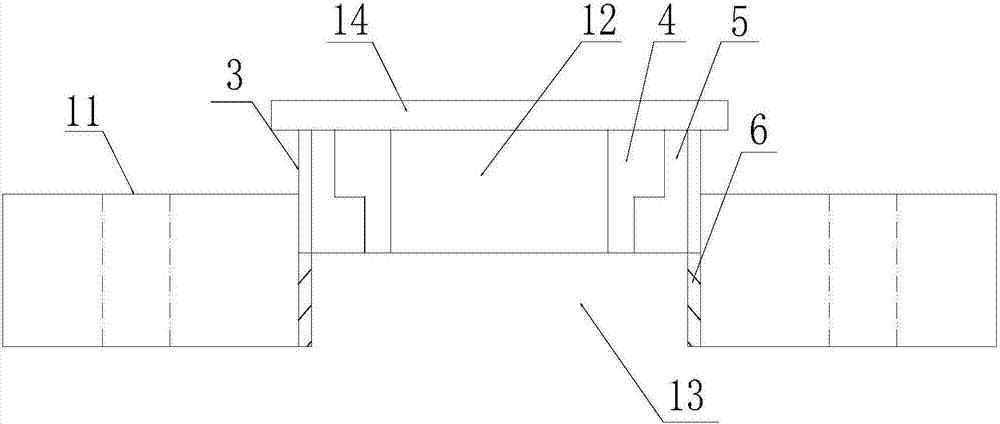

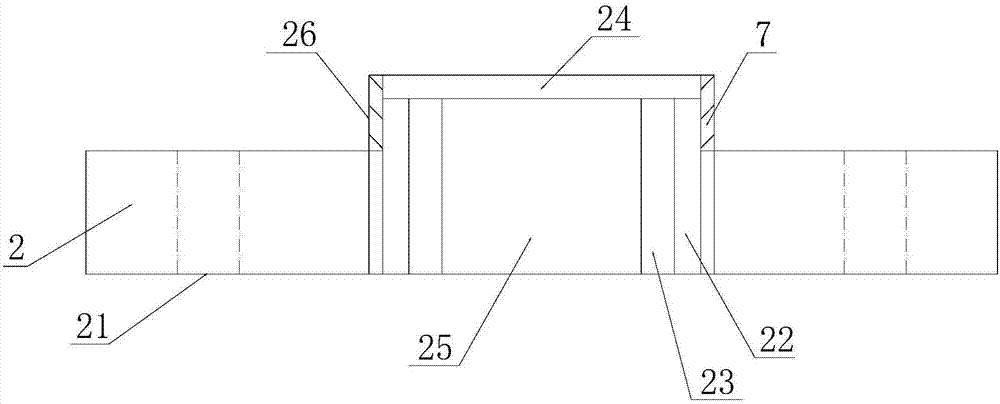

[0015] refer to figure 1 , figure 2 , image 3 with Figure 4 , a flange assembly of the present invention, comprising an upper flange body 1, a lower flange body 2, a first boss 3, a second boss 26, a first gasket 4, a second gasket 5, a water-stop pad 24. The third sealing gasket 22, the first sealing ring 23, the first internal thread 6 of the upper flange body, the first external thread 7 of the lower flange body, the bolt hole 11 of the upper flange body, the bolt hole 21 of the lower flange body, The flange connecting plate 8 and the connecting nut 9, the inside of the upper flange body 1 is provided with a first through hole 12, and the upper surface of the upper flange body 1 is provided with a first boss 3, the upper method The bottom of the flange body 1 is provided with an annular groove 13, the inner wall of the annular groove 13 of the upper flange body 1 is provided with the first internal thread 6 of the upper flange body, and the inside of the lower flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com