Biomass heating stove capable supplementing material automatically

A biomass and heating stove technology, which is used in the combustion of solid fuels, stoves/stoves with hot water devices, and household stoves/stoves, etc. The effect of saving manpower, improving heat production efficiency and timely feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The invention will now be described in more detail with reference to the accompanying drawings, in which preferred embodiments of the invention are shown, it being understood that those skilled in the art may modify the invention described herein and still achieve the advantageous effects of the invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

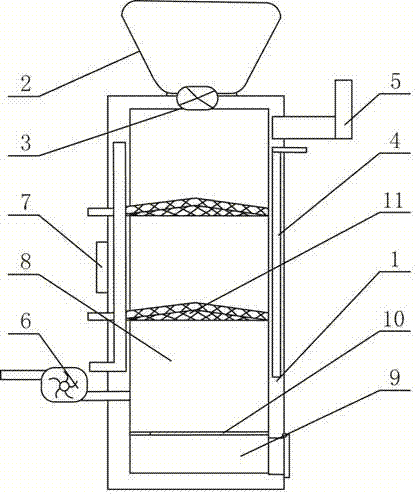

[0009] In the figure, 1. furnace body; 2. storage bin; 3. feeding mechanism; 4. water jacket; 5. flue; 6. oxygen supply mechanism; 7. controller; 8. combustion chamber; 9. ash chamber ; 10, baffle; 11, metal mesh.

[0010] Such as figure 1 As shown, the furnace body 1 is provided with a combustion chamber 8 and an ash chamber 9, the ash chamber 9 is located below the combustion chamber 8, a spring-loaded baffle 10 is provided between the combustion chamber 8 and the ash chamber 9, and a sensor is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com