Corrosion test loading device and test method for short transverse direction of metal plate

A metal sheet, corrosion test technology, applied in the direction of measuring device, weather resistance/light resistance/corrosion resistance, analysis of materials, etc., can solve the problems of unable to load, unable to reach service conditions, unable to process standard tensile specimens, etc. To achieve the effect of adjustable loading size and good neutrality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

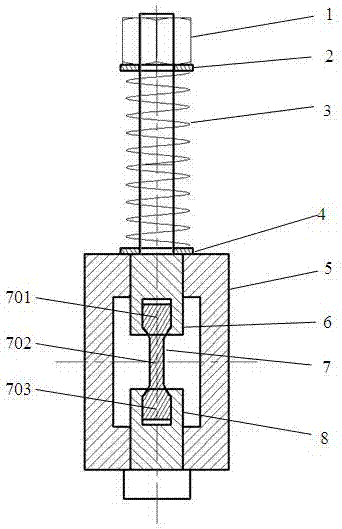

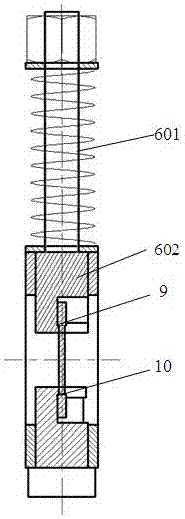

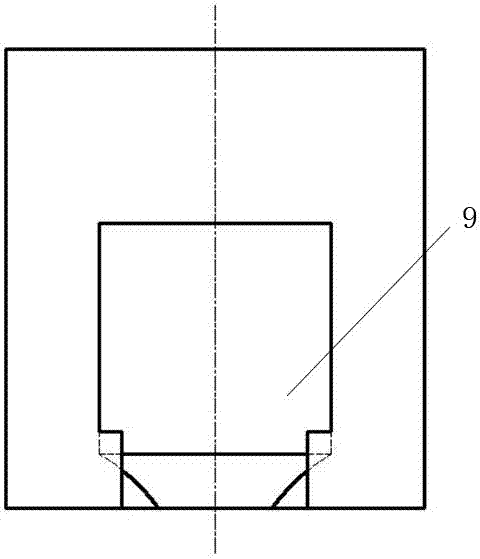

[0036] Example 1: A 304 steel plate with a thickness of 38mm is subjected to a stress of about 100MPa for a long time. A micro-plate tensile sample is taken in the short transverse direction (thickness direction) of the plate, and the size of the clamping end is 10 (width) × 2 (thickness) ) mm, the size of the parallel section of the sample is 5 (width) × 1 (thickness) mm, the length of the parallel section is 14mm, the loading stress is 100MPa, the loading tension is calculated to be 500N, and the known stainless steel spring specification is 4×22×70mm × 8 (wire diameter × outer diameter × length × number of turns), the spring deformation can be calculated to be about 9.3mm, after the loading is completed, the non-parallel section of the sample is encapsulated in paraffin. Place the loaded fixture in the service environment or laboratory environment, and observe the changing behavior of the sample regularly.

Embodiment 2

[0037] Example 2: A 7xxx series aluminum alloy plate with a thickness of 40mm is required to perform an interleaving test under the condition of loading 241MPa according to the customer’s requirements. A small tensile sample is taken from the height direction of the plate, and the size of the clamping end is 10×2mm , the size of the parallel section of the sample is 5×0.7mm, the length of the parallel section is 16mm, the loading stress is 241MPa, the loading tension is calculated to be 843N, and the spring specification is 4×22×70mm×8 (wire diameter×outer diameter×length× Turns), the spring deformation can be calculated to be about 15.9mm, after the loading is completed, the non-parallel section of the sample is encapsulated in paraffin. Place the loaded fixture in the service environment or laboratory environment, and observe the changing behavior of the sample regularly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com