Layer-quality detection method for rock-fill concrete structure and layer-quality evaluation method for rock-fill concrete structure

A quality inspection method and rockfill concrete technology, which are applied in measuring devices, instruments, and analysis of solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of lack of non-destructive testing technology and limited testing methods for the quality of the interlayer junction surface. Achieve the effect of low cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

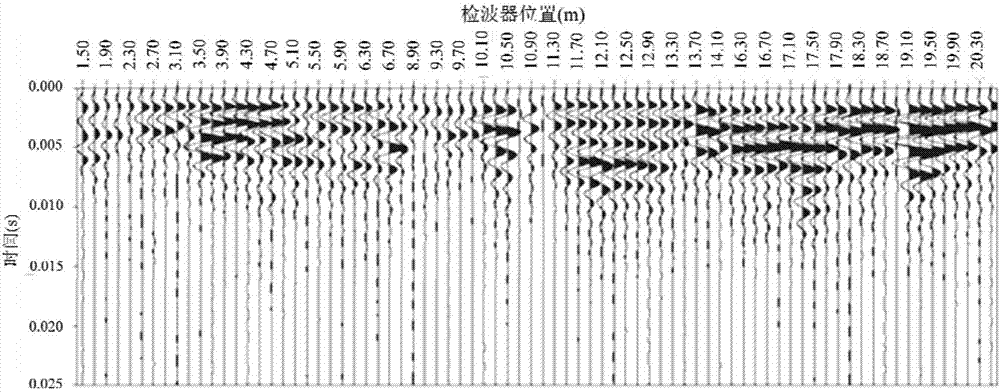

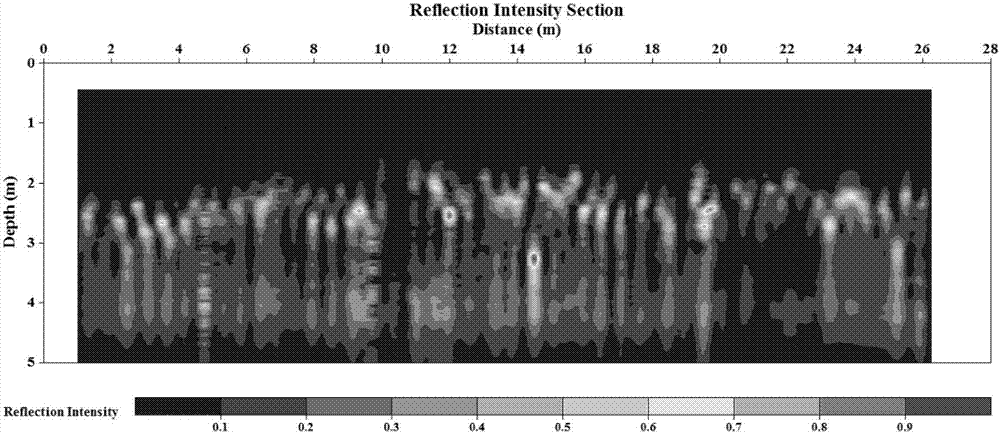

[0053] Using the wave detection device consisting of a data collection device, a wave detector and an elastic wave excitation device, the elastic wave data are collected for the rock-fill concrete structure of the dam when the maintenance age is 2d, 7d, 14d, 28d and 90d.

[0054] Wherein, the distance between the detector and the elastic wave excitation device is 1 m. During the detection process, the elastic wave excitation device-geophone array is set along the upstream and downstream direction of the dam. After the elastic wave data is collected at the first detection point, the wave detection device is placed along the Translate in a straight line, and the distance of each movement is 1m. Collect the elastic wave data corresponding to the detection point after each movement.

[0055] After the detection along the above detection line is completed, the wave detection device is translated in the direction perpendicular to the upstream and downstream, and after the translati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com