Reaction kettle with filler device

A reaction kettle and packing layer technology, applied in the field of stirring reaction equipment, can solve the problems of continuous unfavorable reaction, resetting, time-consuming and laborious, etc., and achieve the effects of increasing efficiency, accurately measuring real-time temperature, and fully reacting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

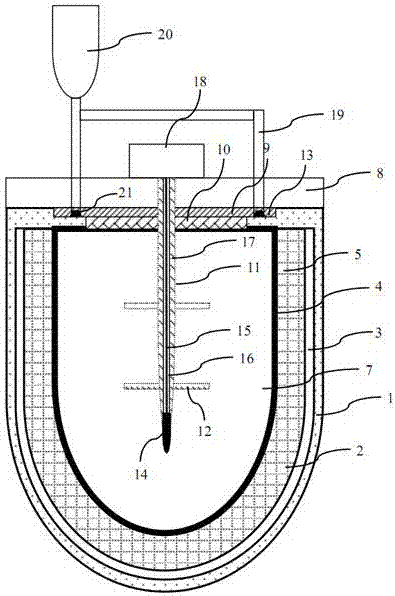

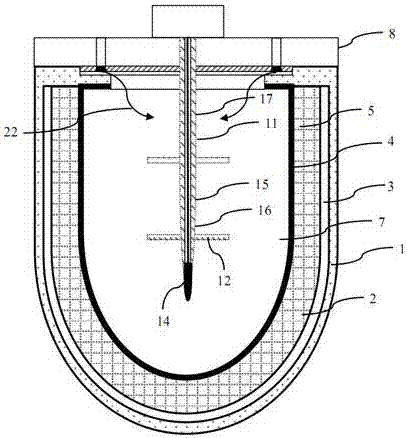

[0016] see figure 1 , the reaction kettle with packing device of the present invention has a cylindrical kettle body and a cover body, and the kettle body includes an outermost shell 1, a heating layer 2 inside the shell 1 and an innermost lining 4 , there is a vacuum isolation cavity 3 between the shell 1 and the heating layer 2, and there is a heating element in the heating layer 2, which is used to electrically heat the lining 4; Board 8, stretchable filler layer 9 and corrosion-resistant heat insulation layer 10;

[0017] Wherein, the kettle body has an upper opening, and the opening has a first step 13, and the edge position of the filler layer 9 and the corrosion-resistant heat insulation layer 10 also forms a second step that matches the first step 13. step, the packing layer 9 is provided with a plurality of filling ports 21 at the horizontal position of the second step, and the filling ports 21 are connected to the packing device 20 through the packing pipe 19; the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com