Tomato adsorption clamping synchronous picking manipulator end actuator

A technology of end effectors and manipulators, applied in the direction of manipulators, agricultural machinery and implements, chucks, etc., can solve the problems of low picking efficiency, low degree of mechanization, low efficiency of tomato picking, etc., to achieve increased clamping speed, high reliability, The effect of convenient and quick adjustment of working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

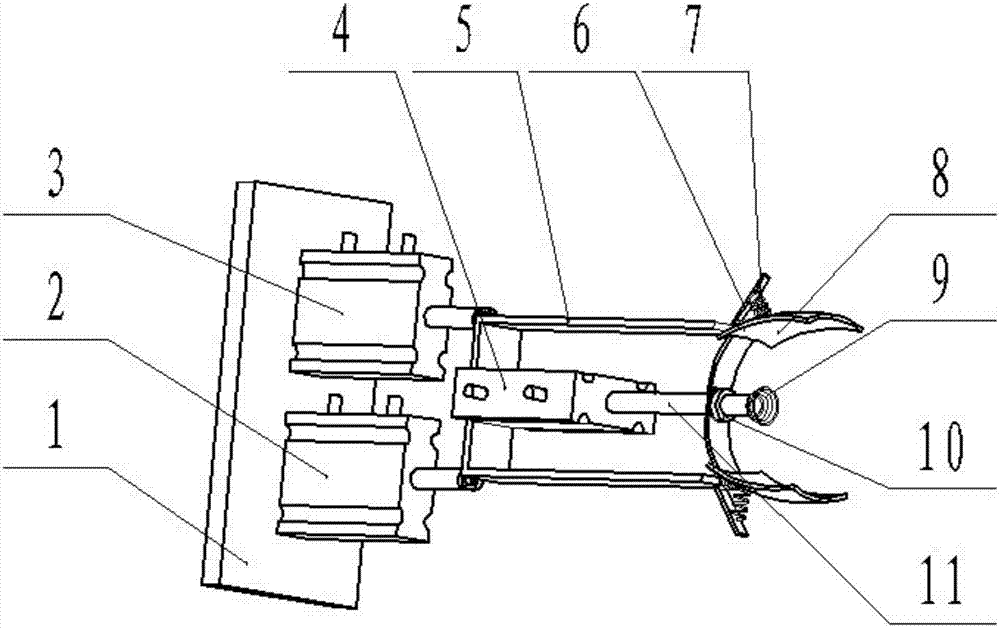

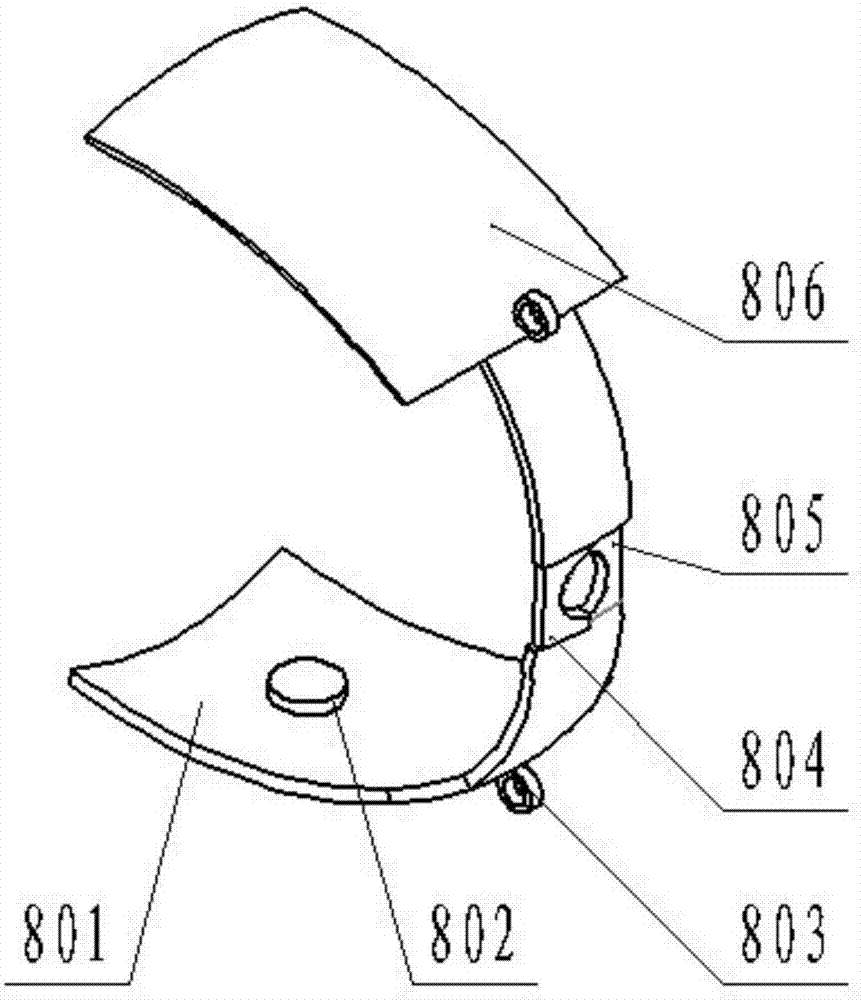

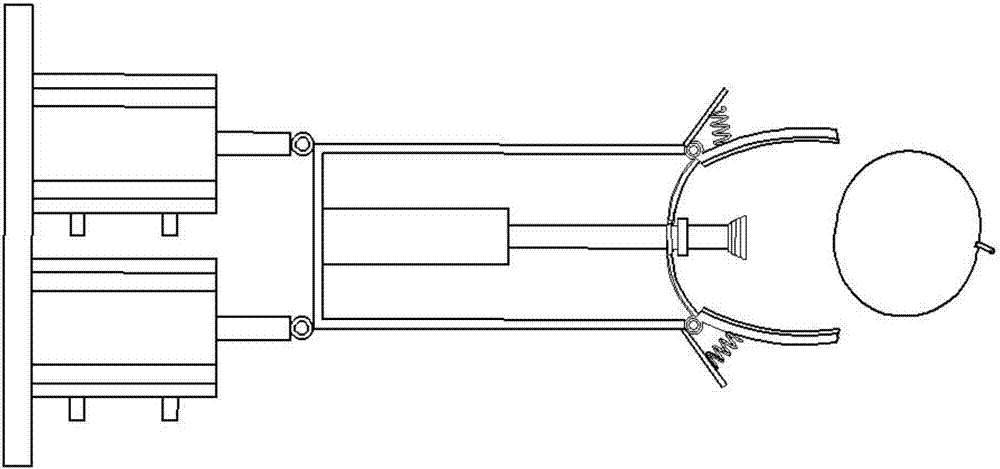

[0029] The end effector of a tomato adsorption and clamping synchronous picking manipulator designed by the present invention uses a multi-joint manipulator to acquire and sense the working environment and tomato information in real time through multi-sensor information fusion to ensure that the fruit is aligned without damaging the tomato 1. Adsorbing fruit, sucking and pulling clamping and swinging and breaking the working process, the invention adopts the picking method of sucking and pulling the fruit to clamp synchronously, and then swinging and breaking the fruit stem, which solves the technical probl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circular diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com