Automatic pay-off machine for terminal crimping machine

A technology of terminal crimping machine and wire pay-off machine, which is applied in the direction of connection, line/collector parts, electrical components, etc. It can solve the problems of wires not meeting quality requirements, unstable wire feeding speed, inconsistent cutting length of wires, etc. , to achieve the effect of novel structure, stable line speed and high production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

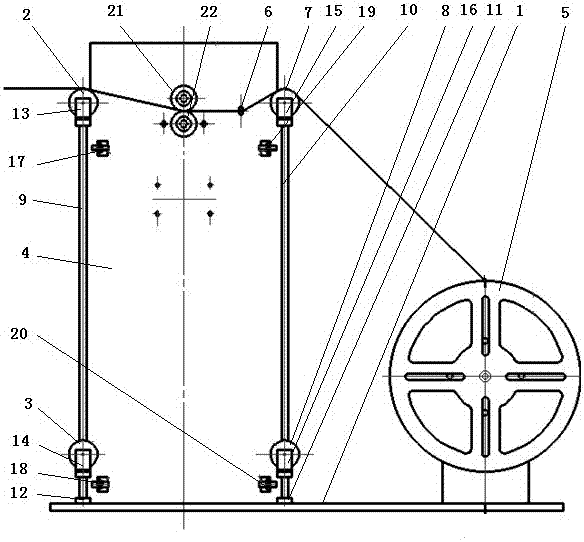

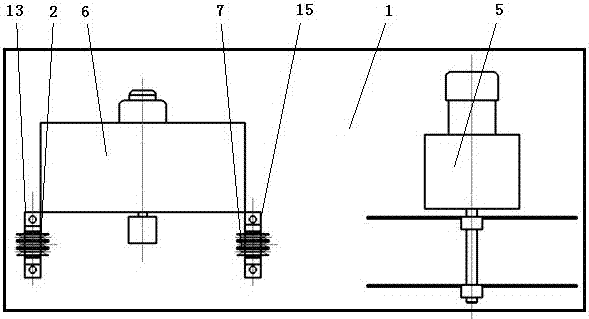

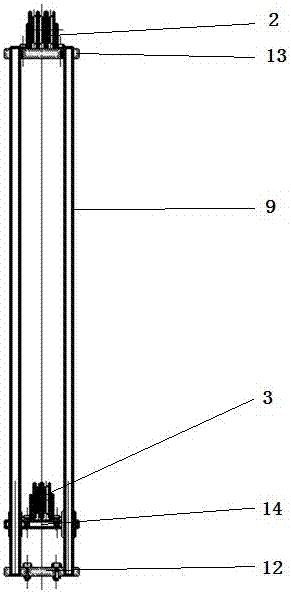

[0018] As shown in the accompanying drawings, an automatic pay-off machine for terminal crimping machine includes a base 1, a guide wheel 2 on the wire feeder, a lower guide wheel 3 on the wire feeder, a support 4 for the wire feeder machine and a wire pay-off machine 5. The wire machine support 4 is provided with a wire feeder 6, which is characterized in that it is provided with a guide wheel 7 on the pay-off line, a lower guide wheel 8 on the pay-off line, a wire-feeding slide bar 9, a pay-off slide bar 10, a pay-off slide bar seat 11, Wire feeding slider seat 12, wire feeding guide wheel seat 13, wire feeding lower guide wheel slide seat 14, pay-off line guide wheel seat 15, wire feeding lower guide wheel slide seat 16, wire feeder start proximity switch 17, wire feeder Stop proximity switch 18, pay-off machine start proximity switch 19, pay-off machine sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com