Method and system for self-adaptive adjustment of mechanical claw grip force of claw machine

A technology of self-adaptive adjustment and mechanical claw, which is applied in manipulators, program-controlled manipulators, indoor games, etc., can solve problems such as the inability to have uniform standards, the error of adjustment results, and the accurate grasp of operating profits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

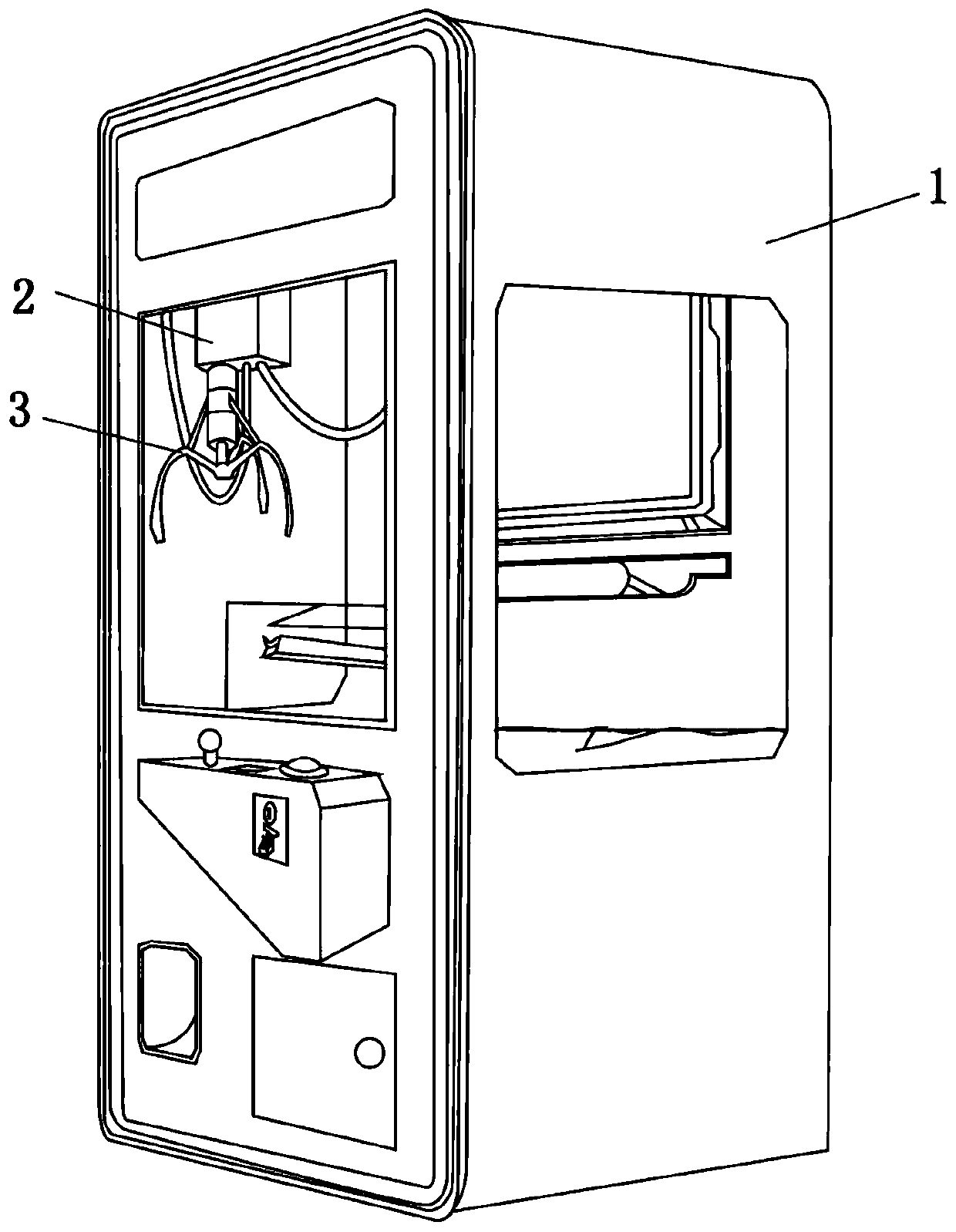

[0033] like figure 1 As shown, the claw machine includes a power supply, a chassis 1 and a crane 2 installed in the chassis 1, a mechanical claw 3 is installed below the crane 2, and the mechanical claw 3 is connected to a motor, and the power supply is connected to the mechanical claw drive circuit. The motor is electrically connected, and the gripping force of the mechanical claw 3 is determined by the driving voltage output from the mechanical claw driving circuit to the motor.

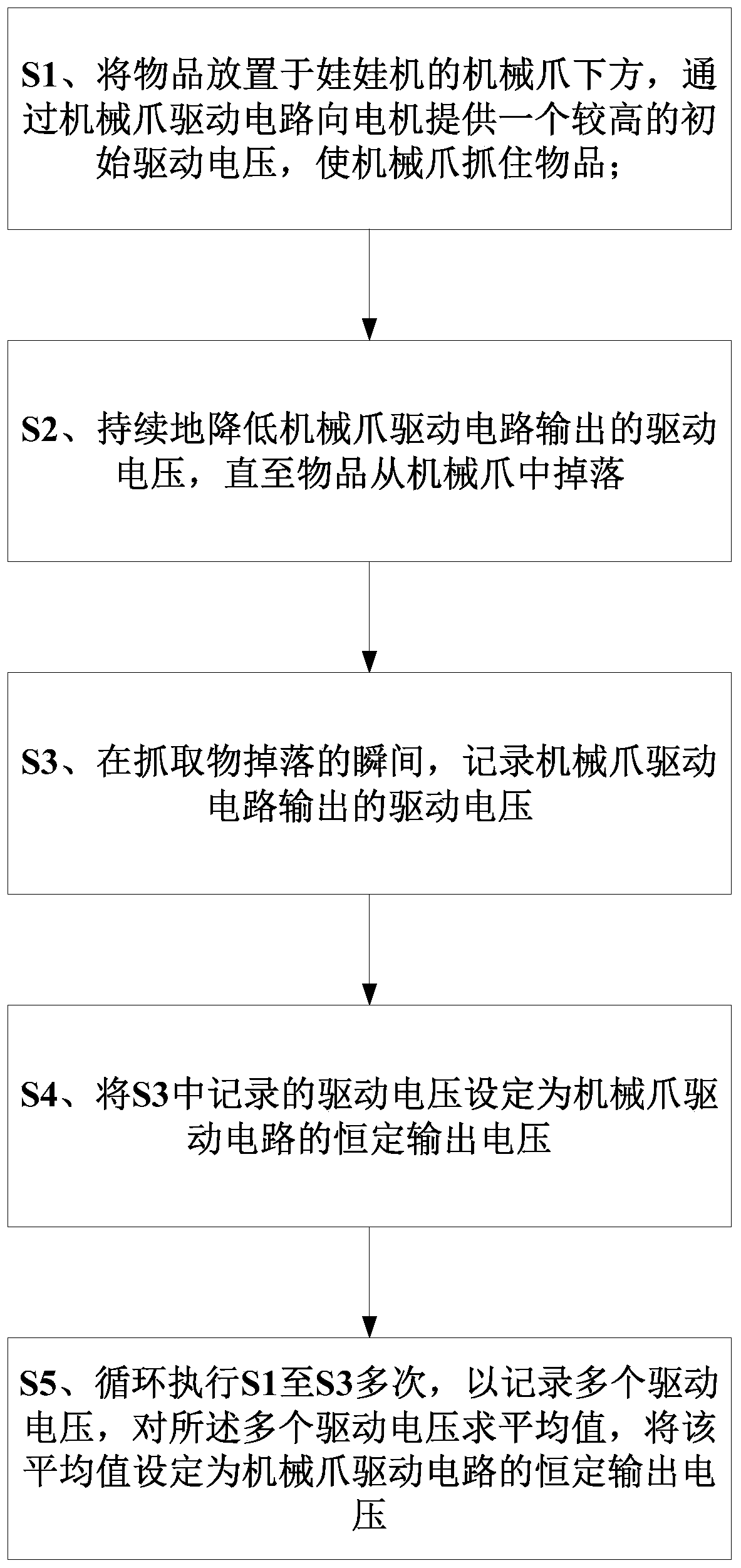

[0034] like figure 2 As shown, specifically, a method for adaptively adjusting the grasping force of mechanical claws of a doll machine provided by the present invention includes:

[0035] S1. Place the item under the mechanical claw of the claw machine, and provide a high initial driving voltage to the motor through the mechanical claw drive circuit, so that the mechanical claw can grab the object;

[0036] S2. Continuously reduce the driving voltage output by the mechanical claw drive circuit ...

Embodiment 2

[0043] The present invention also provides an adaptive adjustment system for mechanical claw gripping force of a doll machine, which includes:

[0044] The driving voltage adjustment module is used to adjust the driving voltage value output by the mechanical claw driving circuit to the motor; before the adjustment starts, the mechanical claw driving circuit outputs a higher initial driving voltage so that the mechanical claw can grasp the object; after the adjustment starts , continuously reducing the drive voltage output by the mechanical claw drive circuit;

[0045] The item drop detection module is used to detect whether the item grasped by the mechanical claw has fallen, and when the item falls, it sends a signal to the voltage recording module;

[0046] The voltage recording module is used to record the driving voltage output by the mechanical claw driving circuit after receiving the signal sent by the object drop detection module;

[0047] The voltage setting module is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com