Diesel locomotive driver controller with load protection function

A driver controller and loading protection technology, which is applied to locomotives with internal combustion engines, locomotives with gas turbines, locomotives, etc., can solve problems such as driver misoperation, hidden safety hazards, and black smoke, so as to reduce accidents and ensure reliability Sexuality and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

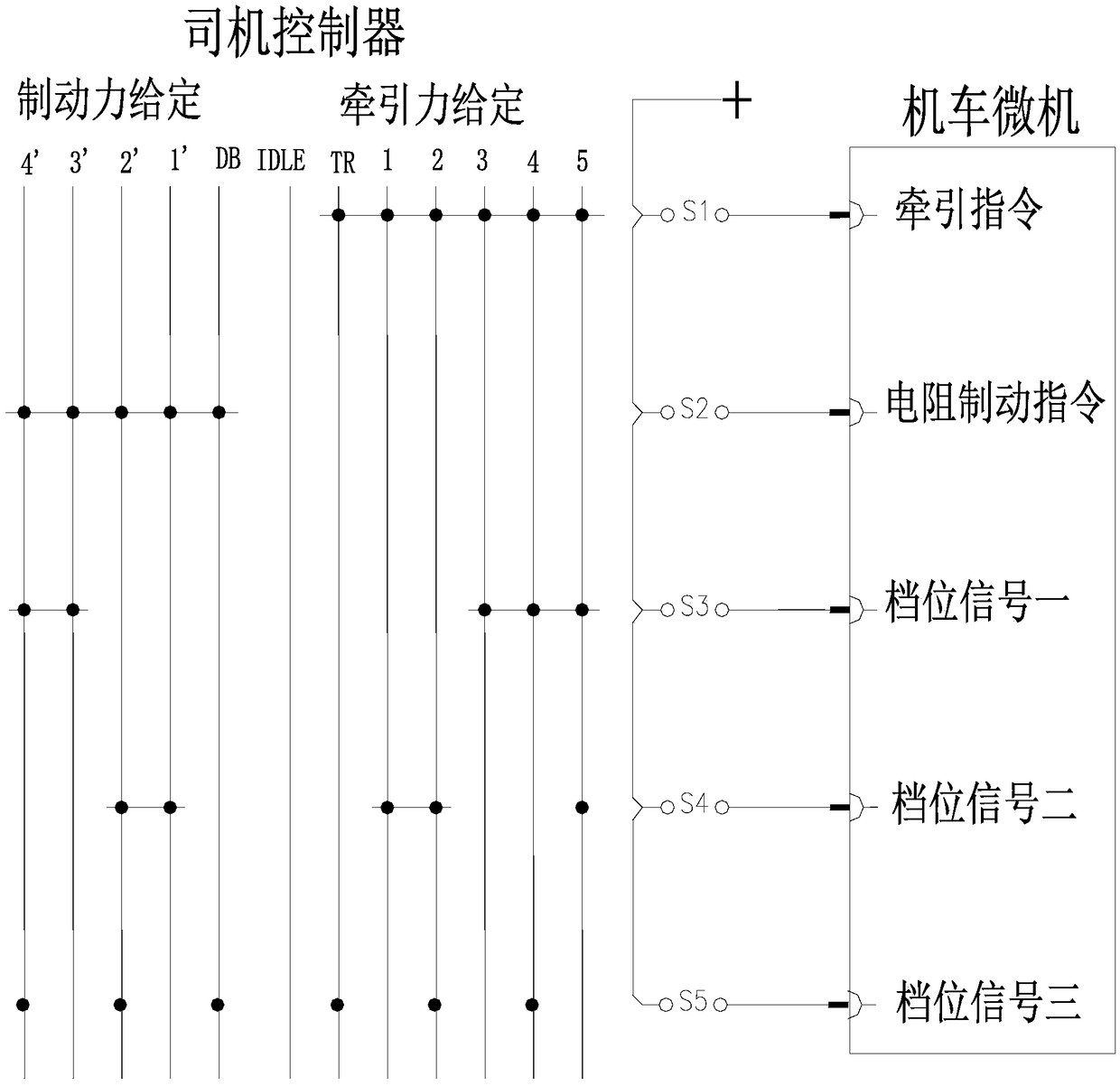

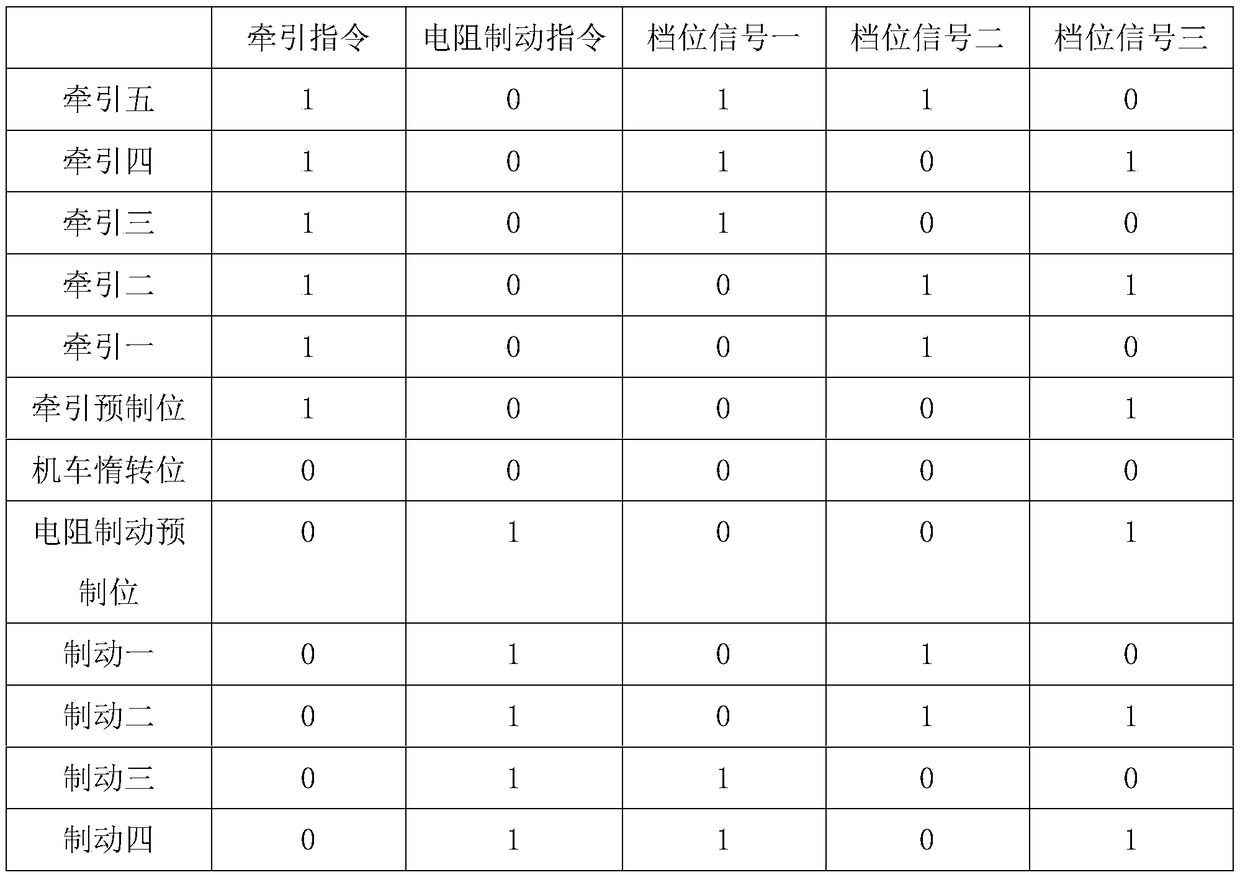

[0020] The driver controller of the diesel locomotive with load protection function will be further described below in conjunction with the accompanying drawings.

[0021] This diesel locomotive driver controller with loading protection function, the upper gear of the driver controller is set to traction position, braking position and locomotive idle shift position, and the traction position is set as traction one 1 and traction two according to the speed of the locomotive from low to high. 2. Traction 3 3, Traction 4 4, Traction 5 5, the brake position is set as Brake 1 1', Brake 2 2', Brake 3 3', Brake 4 4' according to the braking force of the locomotive from small to large , the idle position IDLE of the locomotive is set between the traction one 1 and the brake one 1', the traction prefabricated position TR with offside loading protection function is set between the traction one 1 and the locomotive idle position IDLE, and the brake one 1 Between the locomotive idle posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com