Biological fermentation tank

A biofermentation tank and tank technology, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biomass post-treatment, etc., can solve the problems of low fermentation efficiency, changes in the composition of fermentation products, fermentation The tank cannot observe the material reflection in real time and other problems, so as to achieve the effect of simple operation and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

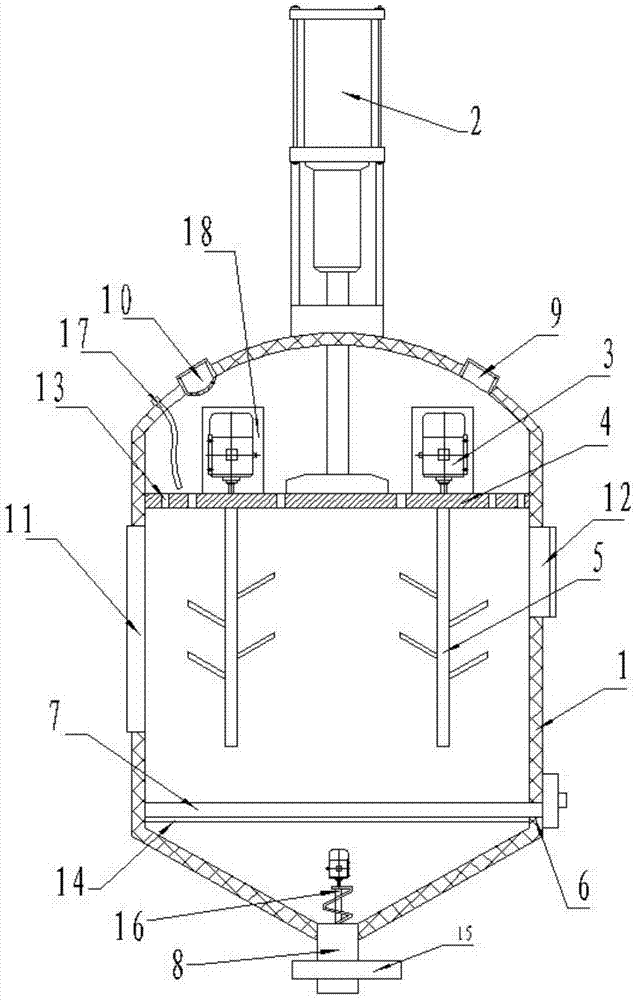

[0015] Such as figure 1 As shown, a biological fermentation tank 1 includes a tank 1, a three-stage telescopic cylinder 2, a frequency conversion motor 3, a cleaning filter press 4 and a stirring rod 5, and the three-stage telescopic cylinder 2 is fixed on the top of the tank 1 , the cleaning filter press plate 4 is horizontally placed on the top of the tank body 1, and the place where the cleaning filter press plate 4 is in contact with the tank body 1 is provided with a sealing strip, and the telescopic end of the three-stage telescopic cylinder 2 extends into the inside of the tank body 1 to connect with the cleaning filter press The plate 4 is fixedly connected to drive the cleaning filter press plate 4 to move up and down; 1-2 variable frequency motors 3 are fixed on the upper end of the cleaning filter press plate 4, and the number of variable frequency motors 3 is set under the cleaning filter press plate 4. Stirring bar 5, and frequency conversion motor 3 rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com