Piece separator

A needle piece and clip technology, which is applied in the field of slicers, can solve the problem of non-existence, and achieve the effects of reducing production costs, being conducive to automatic control, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

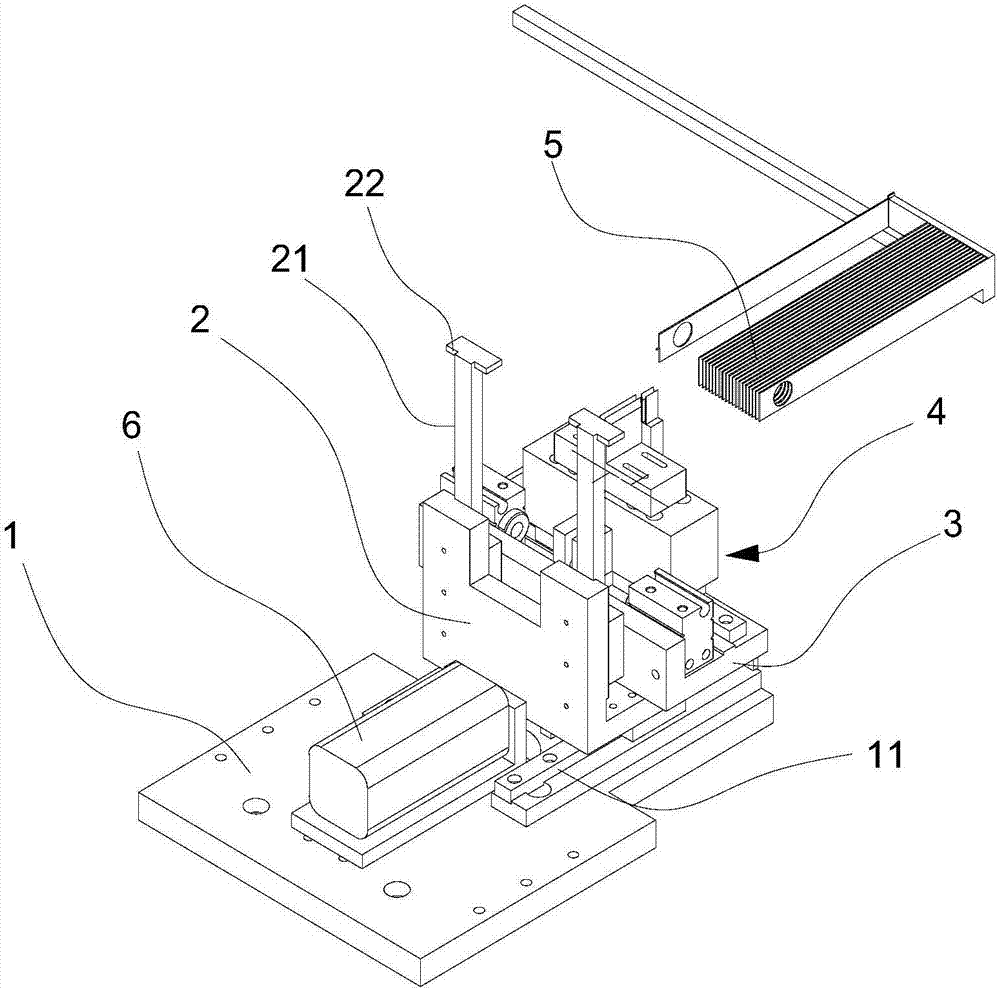

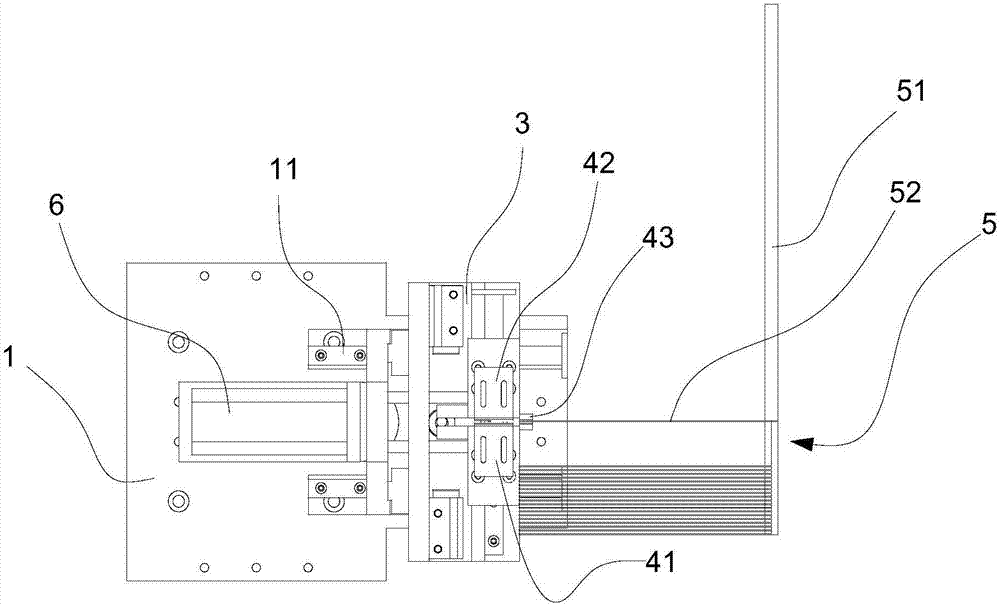

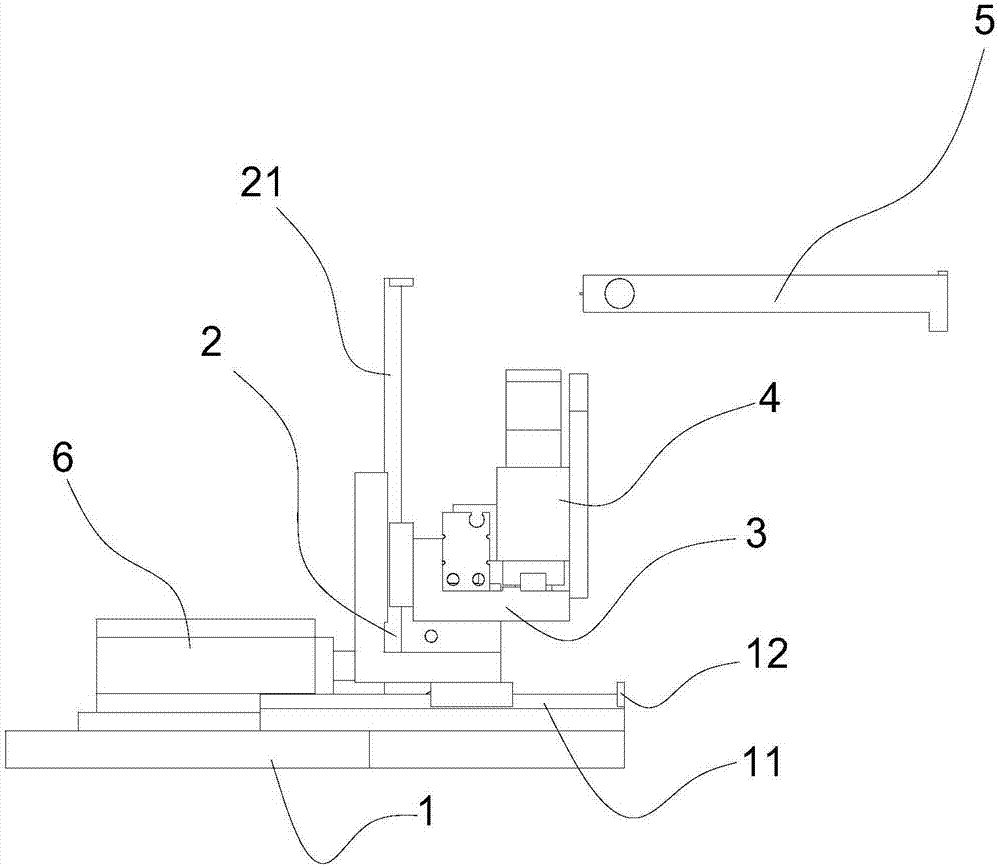

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] like Figure 1 to Figure 13 As shown, the slicer of the present invention includes a base 1 and a needle piece assembly 5; the needle piece assembly 5 includes a needle piece fixing bracket 51 and a plurality of needle pieces 52 parallel to each other; the needle piece 52 One end is fixed on the needle piece fixing bracket 51; the needle piece 52 is evenly distributed along the length direction of the fixing bracket 51;

[0034] The base 1 is provided with a laterally sliding base 2 which is slidably installed in the lateral direction, and the base 1 is provided with a first sliding drive device 6 which drives the laterally sliding base 2 to slide;

[0035] The horizontal sliding base 2 is provided with a vertical sliding base 3 slidingly installed vertically; the vertical sliding base 3 is provided with a slicer 4; the horizontal sliding base 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com