Cross-laminated timber wall dovetail tenon connecting technology and manufacturing method

A connection technology and production method technology, applied in the field of cross-laminated wood wall dovetail joints, can solve problems such as not being able to give full play to the superior performance of CLT

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical advantages and solutions of the present invention clearer, the specific implementation methods will be described below in conjunction with the accompanying drawings.

[0028] The cross-laminated timber wall dovetail joint connection structure in the example is as follows:

[0029] 1. The standard timber used for cross-laminated timber is hemlock sawn timber imported from Canada, with a cross-sectional size of 38mm×140mm.

[0030] 2. The moisture content of cross-laminated wood is 10%.

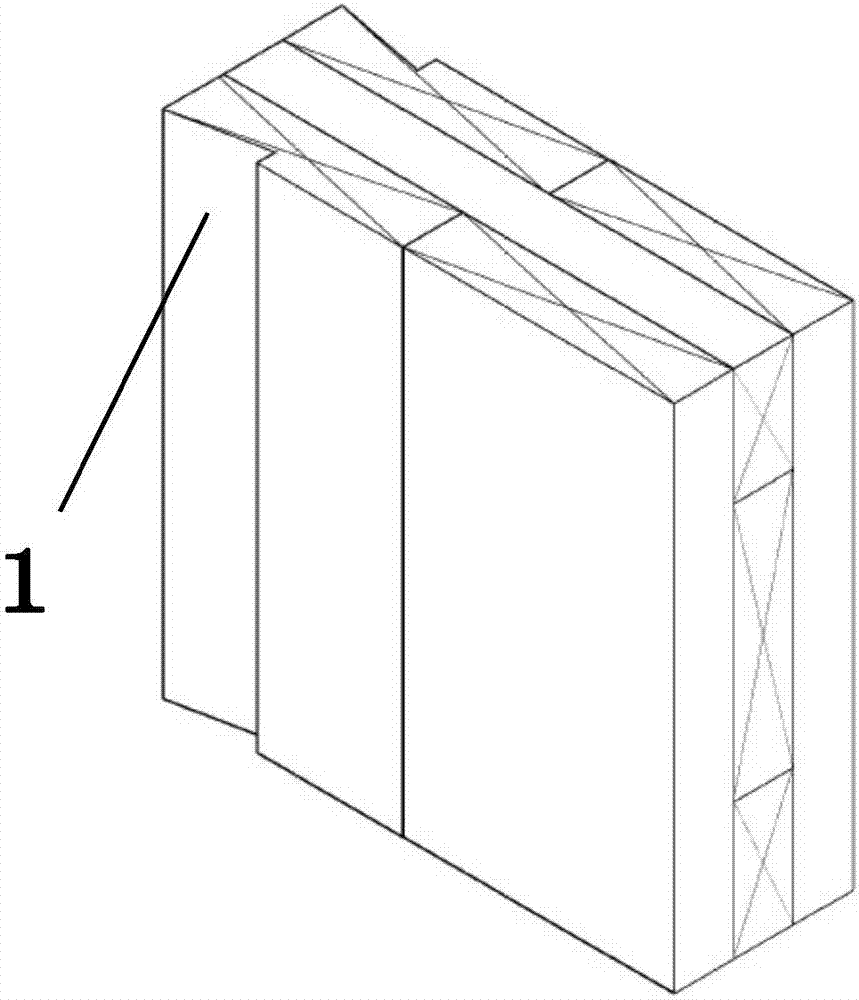

[0031] 3. If figure 1 It is the cross-laminated wood wall dovetail structure of the present invention.

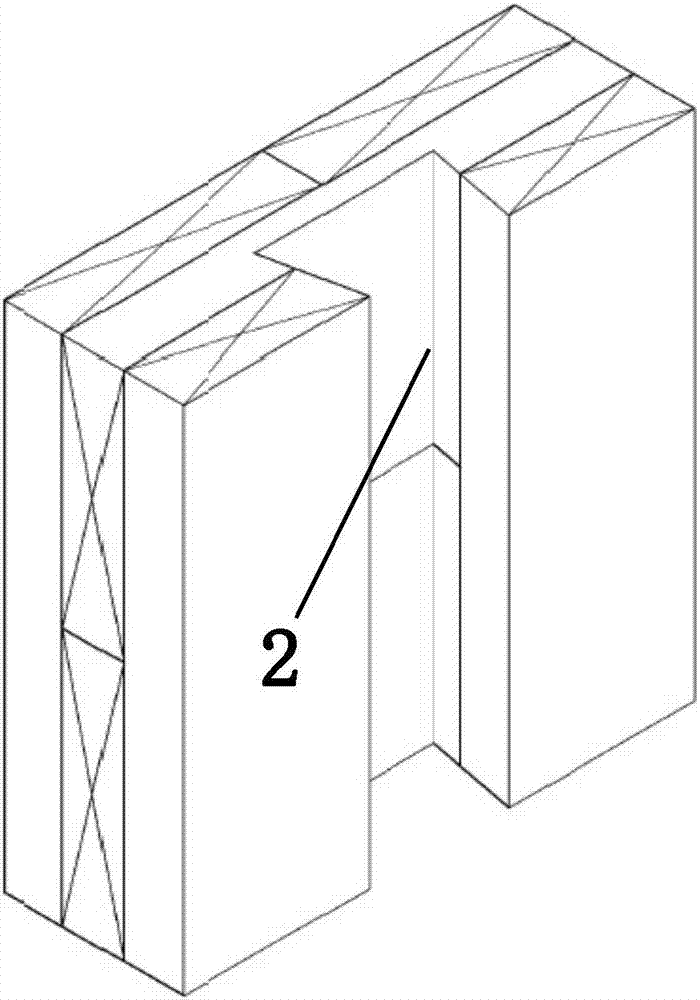

[0032] 4. If figure 2 It is the cross-laminated wood wall dovetail tenon-groove structure of the present invention.

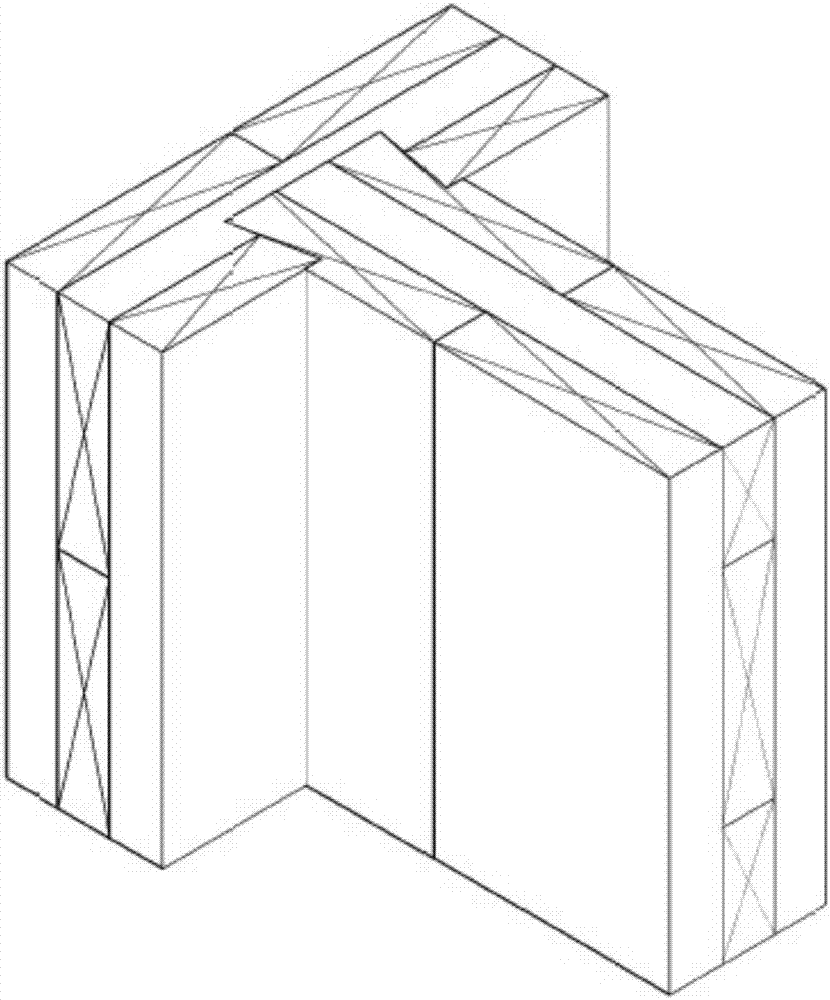

[0033] The dovetail tenons and dovetail tenon grooves of the cross-laminated timber walls are connected together. When constructing a CLT wooden structure building, the hoisting wall can be embedded into the fixed wall through the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com