Installation method for aluminum door window frame with non-leakage rainwater collecting groove

A rainwater collection and installation method technology, applied in the direction of window/door frame, condensate water discharge, etc., can solve the problem of rainwater not being discharged, infiltrating into the steel attached frame, etc., to achieve the effect of simple and fast installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

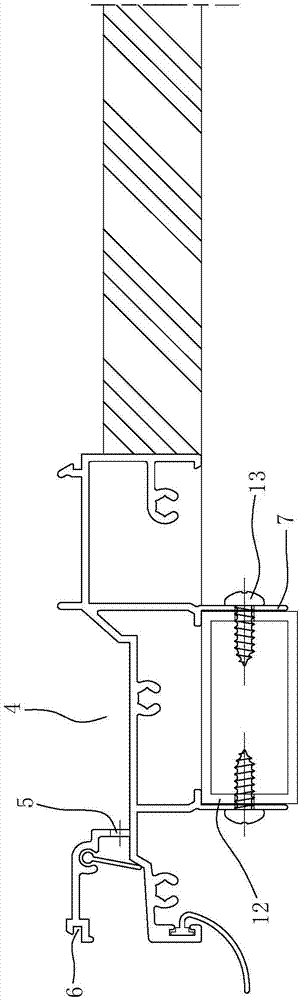

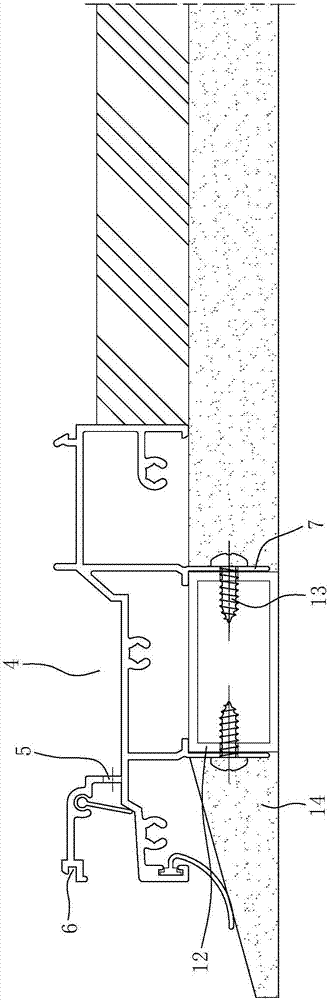

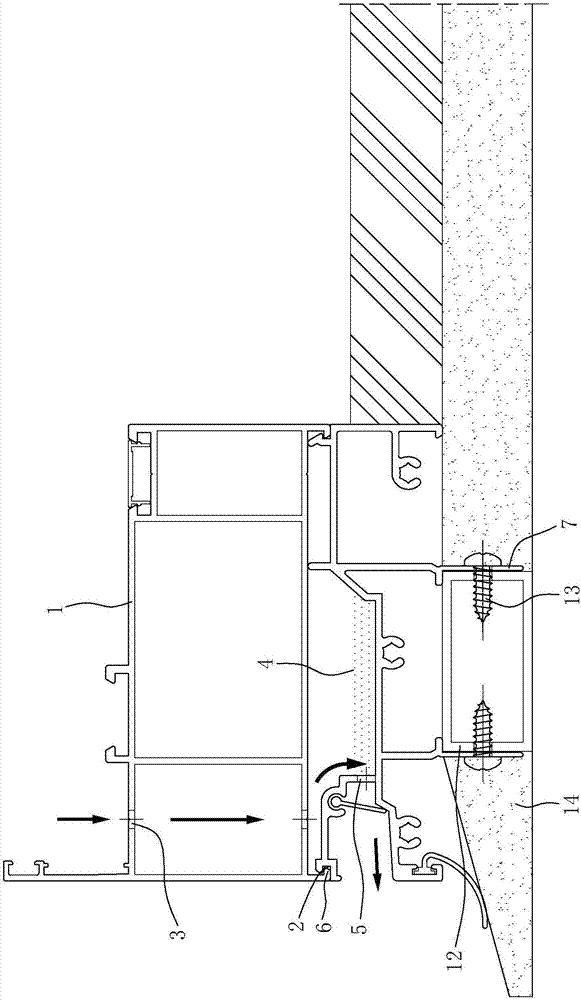

[0012] The technology will be further described below in conjunction with the accompanying drawings.

[0013] The installation method of the aluminum door, window and window frame with the non-seepage rainwater collection tank of the present embodiment is as follows: ① Prepare the clamps 2 on both sides of the lower frame 1 of the window frame, and the bottom of the lower frame 1 is provided with a leaking hole 3, ② Prepare a rainwater collection tank 4, the leak hole 3 on the lower frame 1 communicates with the rainwater collection tank 4, the outer surface of the rainwater collection tank 4 is processed with drainage holes 5, and the upper sides of the rainwater collection tank 4 are provided with card slots 6. The lower part is provided with a pair of side edges 7 protruding downwards. ③ On both sides of the lower frame 1, the first screw 8 is used to fix and install the water retaining plate 10 with the tongue 9, and the tongue 9 is inserted into the rainwater collection ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com