Plug-and-play type compression torsion coupling

A plug-and-play technology for press-torsion couplings, applied in couplings, elastic couplings, mechanical equipment, etc., to achieve the effect of being less likely to be stuck, reducing hysteresis, and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

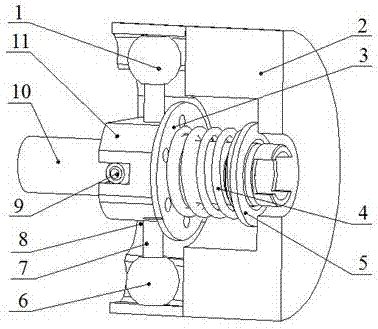

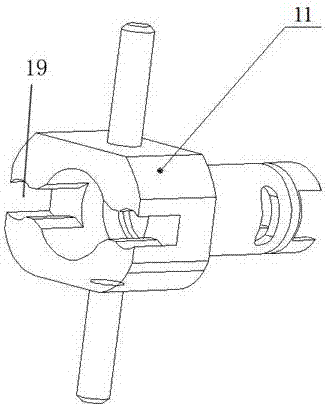

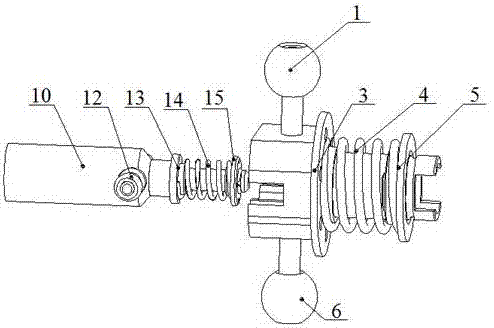

[0030] The plug-and-play compression-torsion coupling of the present invention is composed of a torsion shaft module (follower) and a wedge module (driver).

[0031] The torsion shaft module comprises a torsion shaft 10, a central shaft 12, the third roller 9, the fourth roller, the third spring seat 13, the fourth spring seat 15, inner spring 14 and the second snap ring 16, the central shaft 12 and the torsion The shafts 10 are tightly fitted and connected together in a cross shape, and the third roller 9 and the fourth roller are respectively fixed on both ends of the central shaft 12 with clip springs. When the torsion shaft moves axially, the rolling of the third roller 9 and the fourth roller The axial friction force is greatly reduced. At the same time, when the torsion shaft is twisted, the central shaft acts as a lever to reduce the torsional friction. The third sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com