Application method of adjustable wedge-shaped chuck for tensile strength tests

A tensile strength, adjustable technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of difficult disassembly of test piece residues, reduced bayonet durability, easy leakage of hydraulic cylinders, etc., to achieve easy clamping and The effect of disassembly, small expansion, easy clamping and locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

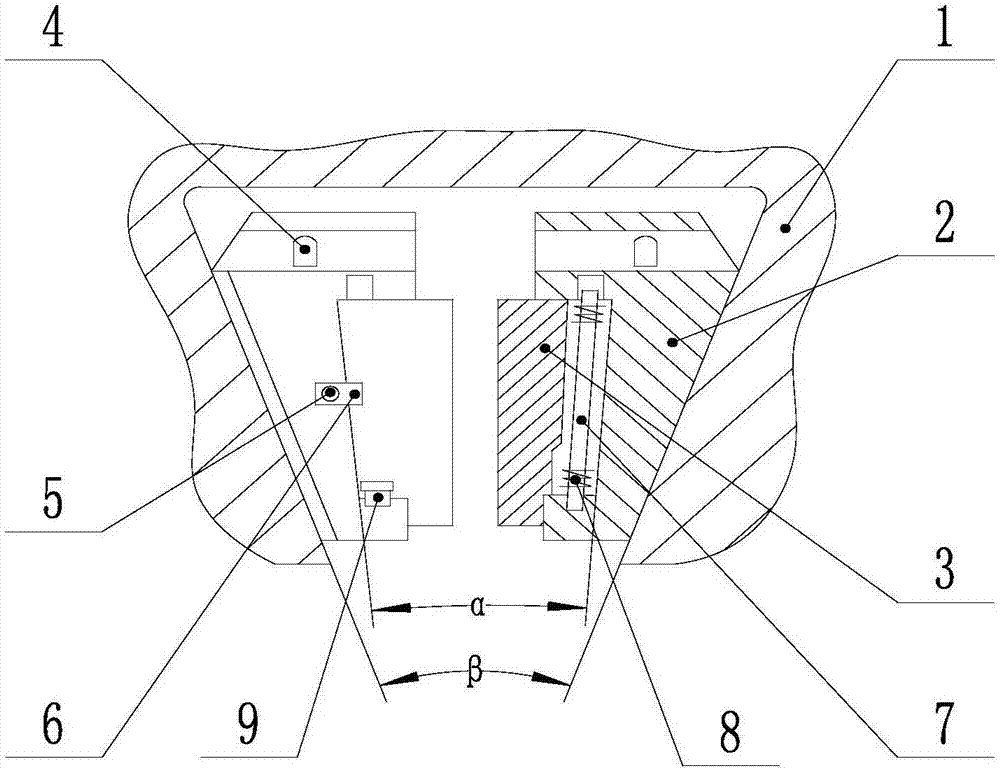

[0027] Such as figure 1 As shown, the method of using the adjustable tensile strength test wedge chuck includes the following steps:

[0028] S1: Set a wedge-shaped opening on the clamp body 1, and install a wedge-shaped splint 2 in the wedge-shaped opening. The wedge-shaped included angle α of the bayonet 3 is smaller than the wedge-shaped included angle β of the wedge-shaped splint 2, and the wedge-shaped bayonet 3 is provided with a convex portion, and the convex portion is embedded and engaged with the inner concave portion of the wedge-shaped splint 2, and the wedge-shaped bayonet 3 is convex The size of the internal part is smaller than the size of the inner concave part of the wedge-shaped splint 2, the ejector rod 4 is installed above the wedge-shaped splint 2, and the installation grooves 9 are arranged at both ends of the inner concave part of the wedge-shaped splint 2, and the two ends of the outer convex part of the wedge-shaped bayonet 3 have coaxial and different...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the wedge-shaped bayonet 3 is arc wedge-shaped, the installation groove 9 is an annular positioning groove, the installation groove 9 of the wedge-shaped splint 2, the through hole of the wedge-shaped bayonet 3 and the guide rod 7 The axis is in the same direction as the arc generatrix of the arc wedge, so as to ensure that the wedge bayonet 3 moves up and down along the wedge angle α.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com